High power density and torque

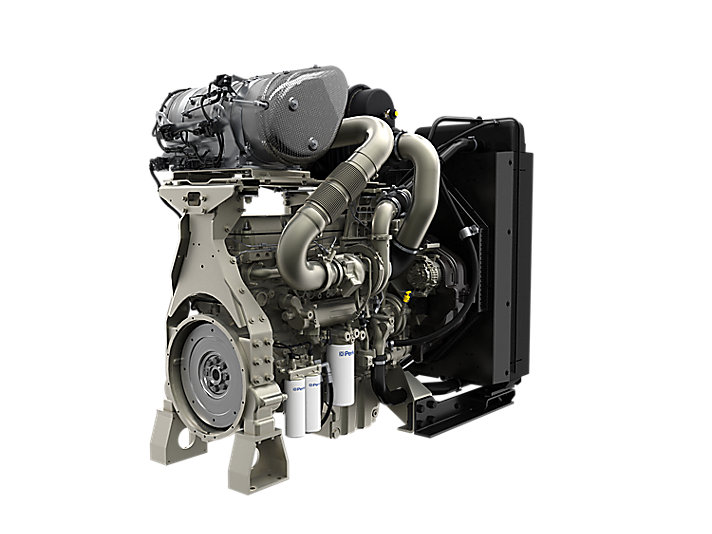

A 6 cylinder, 12.5 litre engine with power up to 430 Nm and peak torque of 2640 Nm to enable engine downsizing.

Low cost of ownership

Optimised design across all systems - fuel, air, electrical, thermal - driving efficiency and lowering total fluid consumption.

Innovative solutions

Perkins design technology and high-efficiency Selective Catalyst Reduction (SCR) enable a compact, lightweight aftertreatment with simple installation requirements.

Maximum uptime

Thermal management designed to provide transparent regeneration, without distraction to the operator or impact to machine performance.

Low installation costs

Fully configurable product with factory solutions such as engine mounted aftertreatment, cooling packs, electrical routing, air cleaners, and all lines necessary for a full power unit - limiting intallation complexity by providing a complete pre-packaged solution.

Think global, act local

The Perkins distributor network offers dedicated experience and knowledge of Perkins diesel engines and provides direct customer focus, protecting your assets through extended service contract options.