Power Rating

| Maximum Power | 416 hp 310 kW |

| Maximum Torque | 1335 lb-ft @ 1400 rpm 1810 Nm @ 1400 rpm |

| Rated Speed | 1800-2200 rpm 1800-2200 rpm |

| Minimum Power | 308 hp 230 kW |

Key Specs

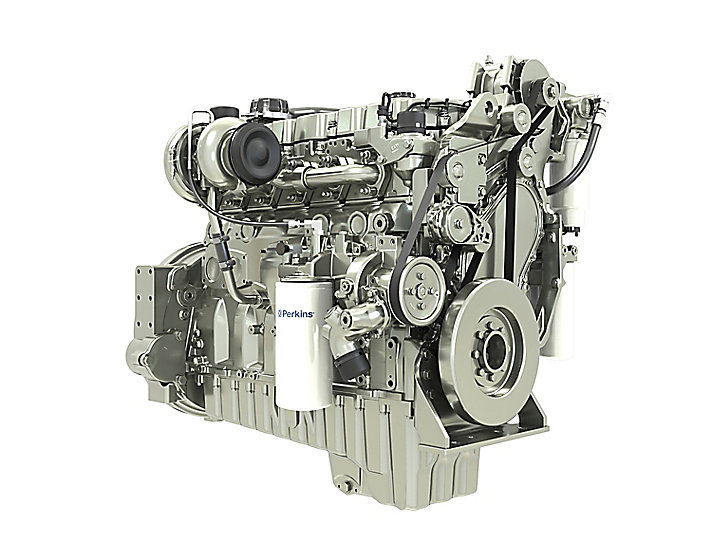

The Perkins® 1706D-E93TA is a 6 cylinder, 9.3 litre engine that produces up to 310 kW (416 hp) of power and 1810 Nm (1335 lb-ft) of torque out of a compact, lightweight package. The 1706D model is a platform extension of the 1706J and meets China Nonroad Stage III, Brazil MAR-1, and UN R96 Stage IIIA emission standards and UN R120 performance standard for measurement of net power and specific fuel consumption.

| Maximum Power | 416 hp 310 kW |

| Maximum Torque | 1335 lb-ft @ 1400 rpm 1810 Nm @ 1400 rpm |

| Rated Speed | 1800-2200 rpm 1800-2200 rpm |

| Minimum Power | 308 hp 230 kW |

| Emissions | China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA |

| Number of Cylinders | 6 inline 6 inline |

| Cycle | 4 stroke 4 stroke |

| Bore | 4.5 in 115 mm |

| Stroke | 5.8 in 149 mm |

| Displacement | 567.5 in³ 9.3 l |

| Compression Ratio | 16.5:1 16.5:1 |

| Aspiration | Turbocharged aftercooled Turbocharged aftercooled |

| Combustion System | Direct injection Direct injection |

| Rotation from Flywheel End | Anti-clockwise Anti-clockwise |

| Aftertreatment | - - |

| Cooling System | Liquid Liquid |

| Length | 44 in 1125 mm |

| Width | 31 in 791 mm |

| Height | 42 in 1068 mm |

| Dry Weight | 1907 lb 865 kg |

| Note 1 | *Final dimensions dependent on selected options *Final dimensions dependent on selected options |

Use the comparison tool to compare detailed specs of Perkins and competitor models.

Compare All Models