Power Rating

| Maximum Power | 577 hp 430 kW |

| Maximum Torque | 1943 lb-ft @ 1400 rpm 2634 Nm @ 1400 rpm |

| Rated Speed | 1800-2100 rpm 1800-2100 rpm |

| Minimum Power | 456 hp 340 kW |

Key Specs

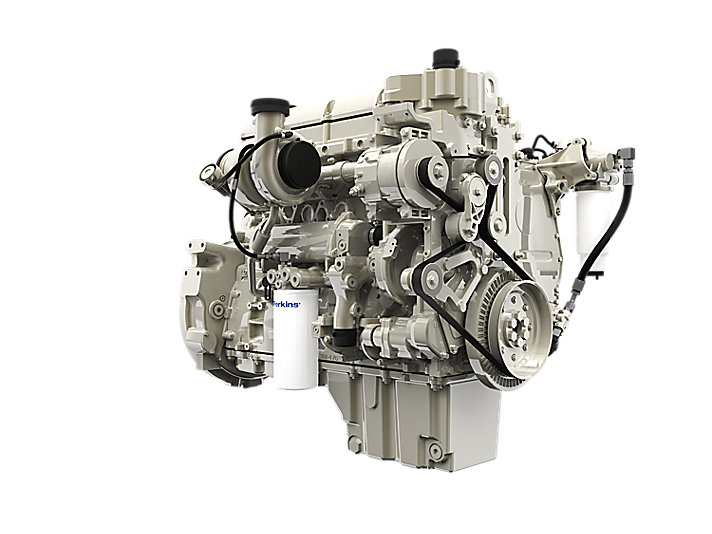

The 2406J/EA-E13TA is a 6 cylinder, 12.5 litre engine capable of producing up to 430 kW (577 hp) of power and 2634 Nm (1943 lb-ft) of torque out of a compact, lightweight package. The 2406J-E13TA is certified to EU Stage V/U.S. EPA Tier 4 Final, along with Japan 2014 (Tier 4 Final) and Korea Stage V. The 2406EA-E13TA is certified to China Nonroad (NR) Stage IV. This simplifies the decision-making process for global customers by allowing them to standardise their worldwide product offering and reap the benefits of common installation, maintenance and service requirements from a single supplier solution.

| Maximum Power | 577 hp 430 kW |

| Maximum Torque | 1943 lb-ft @ 1400 rpm 2634 Nm @ 1400 rpm |

| Rated Speed | 1800-2100 rpm 1800-2100 rpm |

| Minimum Power | 456 hp 340 kW |

| Emissions | EU Stage V, U.S. EPA Tier 4 Final, Japan 2014, Korea tier 4 Final EU Stage V, U.S. EPA Tier 4 Final, Japan 2014, Korea tier 4 Final |

| Number of Cylinders | 6 inline 6 inline |

| Cycle | 4 stroke 4 stroke |

| Bore | 5.1 in 130 mm |

| Stroke | 6.2 in 157 mm |

| Displacement | 762.8 in³ 12.5 l |

| Compression Ratio | 15.8:1 15.8:1 |

| Aspiration | Turbocharged aftercooled Turbocharged aftercooled |

| Combustion System | Direct injection Direct injection |

| Rotation from Flywheel End | Anti-clockwise Anti-clockwise |

| Aftertreatment | DOC+DPF+SCR DOC+DPF+SCR |

| Cooling System | Liquid Liquid |

| Length | 50 in 1274 mm |

| Width | 39 in 994 mm |

| Height | 45 in 1134 mm |

| Dry Weight | 2480 lb 1125 kg |

| Note 1 | *Final dimensions dependent on selected options *Final dimensions dependent on selected options |

Use the comparison tool to compare detailed specs of Perkins and competitor models.

Compare All Models