Power Rating

| Maximum Power | 74 hp 55 kW |

| Maximum Torque | 221 lb-ft @ 1600 rpm 300 Nm @ 1600 rpm |

| Rated Speed | 2200 - 2400 rpm 2200 - 2400 rpm |

| Minimum Power | 74 hp 55 kW |

Key Specs

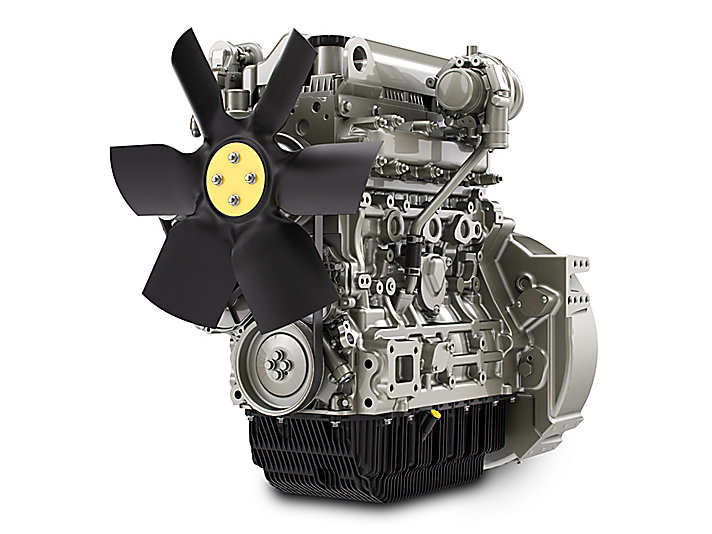

The 904 Series engines offer a compact power solution for off-highway applications in construction, agriculture and industrial.For our customers these compact, 4 cylinder engines provide excellent performance in power, peak and low speed torque, fuel consumption and transient response.Reliability and easy service access are integral to the design of the engines. It is available with a range of installation options to enable OEMs to minimise the size of the engine bay of their machines.

Hydraulic tappets, multi-vee belts and long service intervals enable low cost maintenance

Quality, reliability and consistency are assured. Our facilities worldwide employ the same efficient processes, the same tested and validated components, and the same stringent quality controls wherever your engines are manufactured.

| Maximum Power | 74 hp 55 kW |

| Maximum Torque | 221 lb-ft @ 1600 rpm 300 Nm @ 1600 rpm |

| Rated Speed | 2200 - 2400 rpm 2200 - 2400 rpm |

| Minimum Power | 74 hp 55 kW |

| Emissions | UN ECE R96 Stage IIIA, Brazil MAR-1 UN ECE R96 Stage IIIA, Brazil MAR-1 |

| Number of Cylinders | 4 inline 4 inline |

| Cycle | 4 stroke 4 stroke |

| Bore | 3.5 in 90 mm |

| Stroke | 4.3 in 110 mm |

| Displacement | 171 in³ 2.8 l |

| Compression Ratio | 17.0:1 17.0:1 |

| Aspiration | Turbocharged Turbocharged |

| Combustion System | Direct injection Direct injection |

| Rotation from Flywheel End | Anti-clockwise Anti-clockwise |

| Aftertreatment | - - |

| Cooling System | Liquid Liquid |

| Length | 24.9 in 633 mm |

| Width | 21.2 in 538 mm |

| Height | 30.9 in 786 mm |

| Dry Weight | 705 lb 320 kg |

| Note 1 | *Final dimensions dependent on selected options *Final dimensions dependent on selected options |

Use the comparison tool to compare detailed specs of Perkins and competitor models.

Compare All Models