We have designed the Perkins 2000 range with optimised fluid (DEF and Fuel) consumption in mind, matching it to the operating cycles of a wide range of equipment and applications. Low cost maintenance is achieved through a minimum 5,000 hour aftertreatment service interval and 500 hour oil change intervals. Transparent regeneration of the aftertreatment provides minimum downtime.

The Perkins 2000 range is suitable for the toughest operating conditions. Built in a world class manufacturing facility, and with proven core engine designs you can be assured of many hours of productive life. Aftertreatment designed to perform through the whole work cycle of the engine, supporting productivity of machines in all conditions.

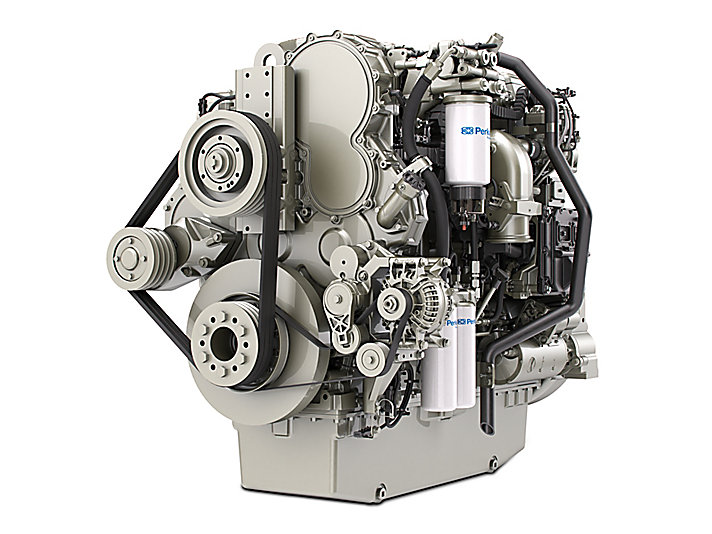

Features built into the 2000 Range provide opportunities to reduce the cost of installation into your machine. With a compact package size of the engine, supported by multiple options available to support optimisation for your application. Supported by our expertise of application installations, the knowledge required to improve total integration is at all times you work with Perkins. Flexibility in aftertreatment installation, including horiztonal and vertical options.