2400 Series

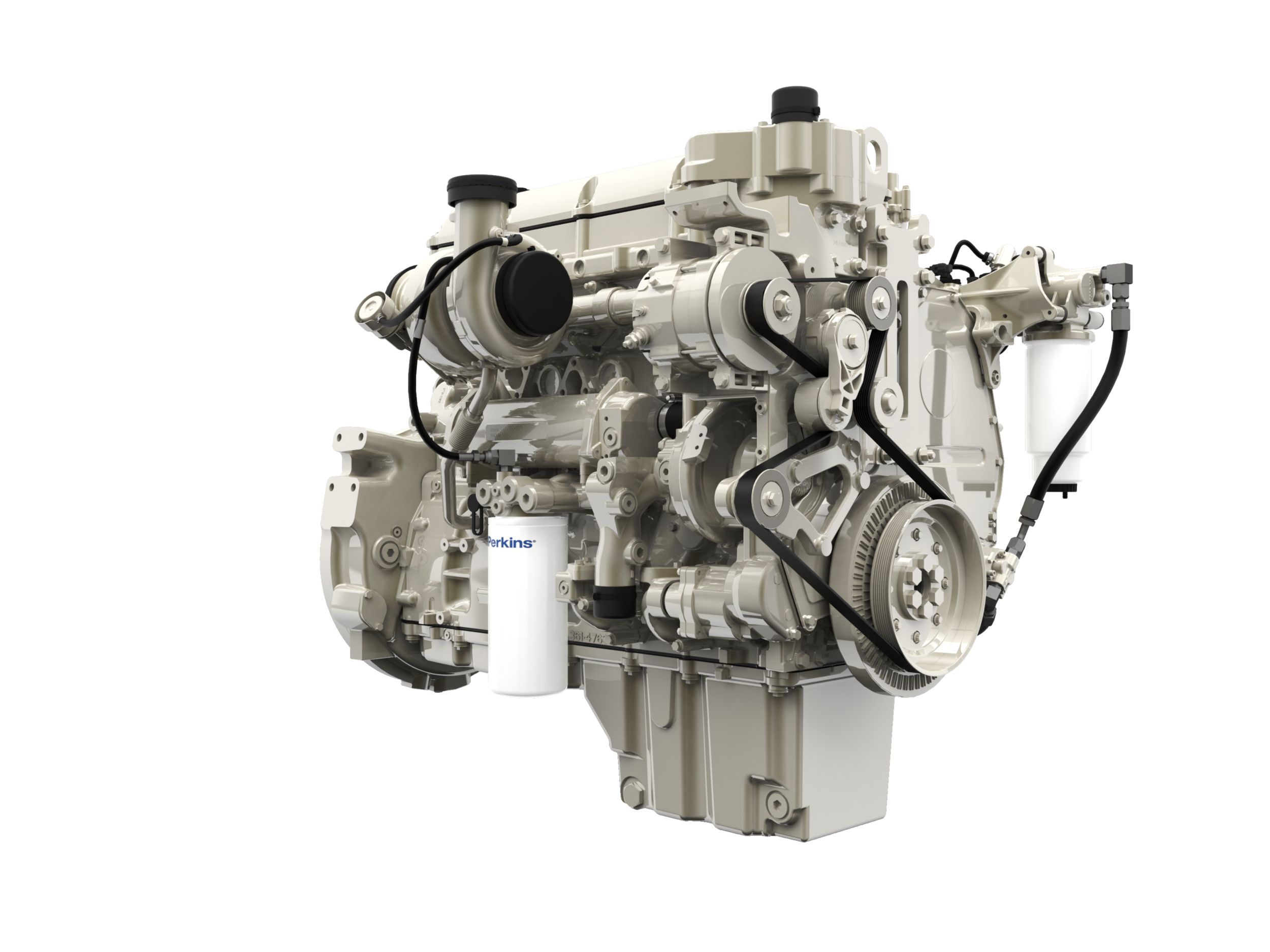

Perkins has expanded its industrial engine range with the addition of the 2400 Series. Focused on delivering power density and performance, the 12.5 litre engine will be capable of power up to 430 kW (577 hp).

The 2406J utilises advanced technologies including a compact aftertreatment, non-EGR (Exhaust Gas Recirculation) air system and the latest electronics to provide high performance characteristics while lowering the customer’s cost of ownership. The engine also offers outstanding power density, enabling OEMs to downsize their engine platform without sacrificing performance or reliability. It is designed to allow simple, low-cost installations with low heat rejection for optimal cooling package sizing and features like engine mounted aftertreatment and installed radiators from the factor to reduce installation cost.

The 2406J is certified to EU Stage V, U.S. EPA Tier 4 Final, Japan 2014 and Korea Tier 4 Final. This simplifies the decision-making process for global customers but allowing them to standardise their worldwide product offering and reap the benefits of common installation, maintenance and service requirements from a single supplier solution.

Perkins® 2400 Series engine range

-

- Maximum Power

- 577 hp

- 430 kW

- Maximum Torque

- 1943 lb-ft @ 1400 rpm

- 2634 Nm @ 1400 rpm

- Emissions

- China NR IV

- China NR IV

2406EA-E13TA

The 2406J/EA-E13TA is a 6 cylinder, 12.5 litre engine capable of producing up to 430 kW (577 hp) of power and 2634 Nm (1943 lb-ft) of torque out of a compact, lightweight package. The 2406J-E13TA is certified to EU Stage V/U.S. EPA Tier 4 Final, along with Japan 2014 (Tier 4 Final) and Korea Stage V. The 2406EA-E13TA is certified to China Nonroad (NR) Stage IV. This simplifies the decision-making process for global customers by allowing them to standardise their worldwide product offering and reap the benefits of common installation, maintenance and service requirements from a single supplier solution.

Learn More -

- Maximum Power

- 577 hp

- 430 kW

- Maximum Torque

- 1943 lb-ft @ 1400 rpm

- 2634 Nm @ 1400 rpm

- Emissions

- EU Stage V, U.S. EPA Tier 4 Final, Japan 2014, Korea tier 4 Final

- EU Stage V, U.S. EPA Tier 4 Final, Japan 2014, Korea tier 4 Final

2406J-E13TA

The 2406J/EA-E13TA is a 6 cylinder, 12.5 litre engine capable of producing up to 430 kW (577 hp) of power and 2634 Nm (1943 lb-ft) of torque out of a compact, lightweight package. The 2406J-E13TA is certified to EU Stage V/U.S. EPA Tier 4 Final, along with Japan 2014 (Tier 4 Final) and Korea Stage V. The 2406EA-E13TA is certified to China Nonroad (NR) Stage IV. This simplifies the decision-making process for global customers by allowing them to standardise their worldwide product offering and reap the benefits of common installation, maintenance and service requirements from a single supplier solution.

Learn More

High power and density torque

A 6-cylinder, 12.5 litre engine with power up to 430 kW and peak torque of 2640 Nm to enable downsizing.

Maximum uptime

Thermal management designed to provide transparent regeneration, without distraction to the operator or impact to machine performance.

Dependable power

World-class manufacturing capability and processes coupled with proven core engine designs. Over 109 million off-highway field hours assure reliability, quiet operation and many hours of productive life.’

-

Request Consultation

If you're ready to receive trusted advice from a Perkins expert, speak to our team today.

Connect with us -

Powernews Q4 2025

Our digital magazine with the latest news, interviews and analysis.

Read more -

Distributor locator

Your regional Perkins Distributor can provide local, on-the-ground engine support.

Learn More