Renewable fuels are derived from renewable resources such as planted crops (soy, palm, rapeseed, etc.), used cooking oil, animal fat, biomass, algae, and others. When considering the life cycle of the fuel, renewable fuels have lower-carbon footprints. Renewable fuels that are derived from fats and oils may be processed through hydrotreating. The result is a high paraffinic renewable diesel (RD), also called hydrotreated vegetable oil (HVO), that can be used in diesel engines.

Biomass and syn gas can be converted into liquid fuels through various processes and their products are typically know as biomass-to-liquid (BTL) or gas-to-liquid (GTL). Depending on the original feedstock these products may be renewable. BTL, GTL and HVO have similar chemistries and performance specifications, and all can be used in diesel engines.

Note that lower-carbon intensity fuels covered in this paper are different than biodiesel fuel.

Lower-carbon intensity fuels are typically paraffinic hydrocarbons, hence these fuels, whether at 100% or blended, can be used as drop-in replacements for diesel fuel. These fuels have many potential benefits:

In order to be applicable for Perkins diesel engines, Perkins recommends that renewable and lower-carbon intensity fuels meet the latest version of any of the following specifications:

Renewable and lower-carbon intensity fuels that meet the requirements listed above can be used at:

* see your engine’s Operation Maintenance Manual for specific biodiesel limits on your engine

Here is Perkins’ guidance and potential impacts for the use of renewable and lower-carbon fuels according to the specifications detailed above:

Perkins is continuously following the development of renewable and lower-carbon intensity fuels, and is involved in the development of appropriate specifications to ensure the successful application of these fuels in Perkins engines.

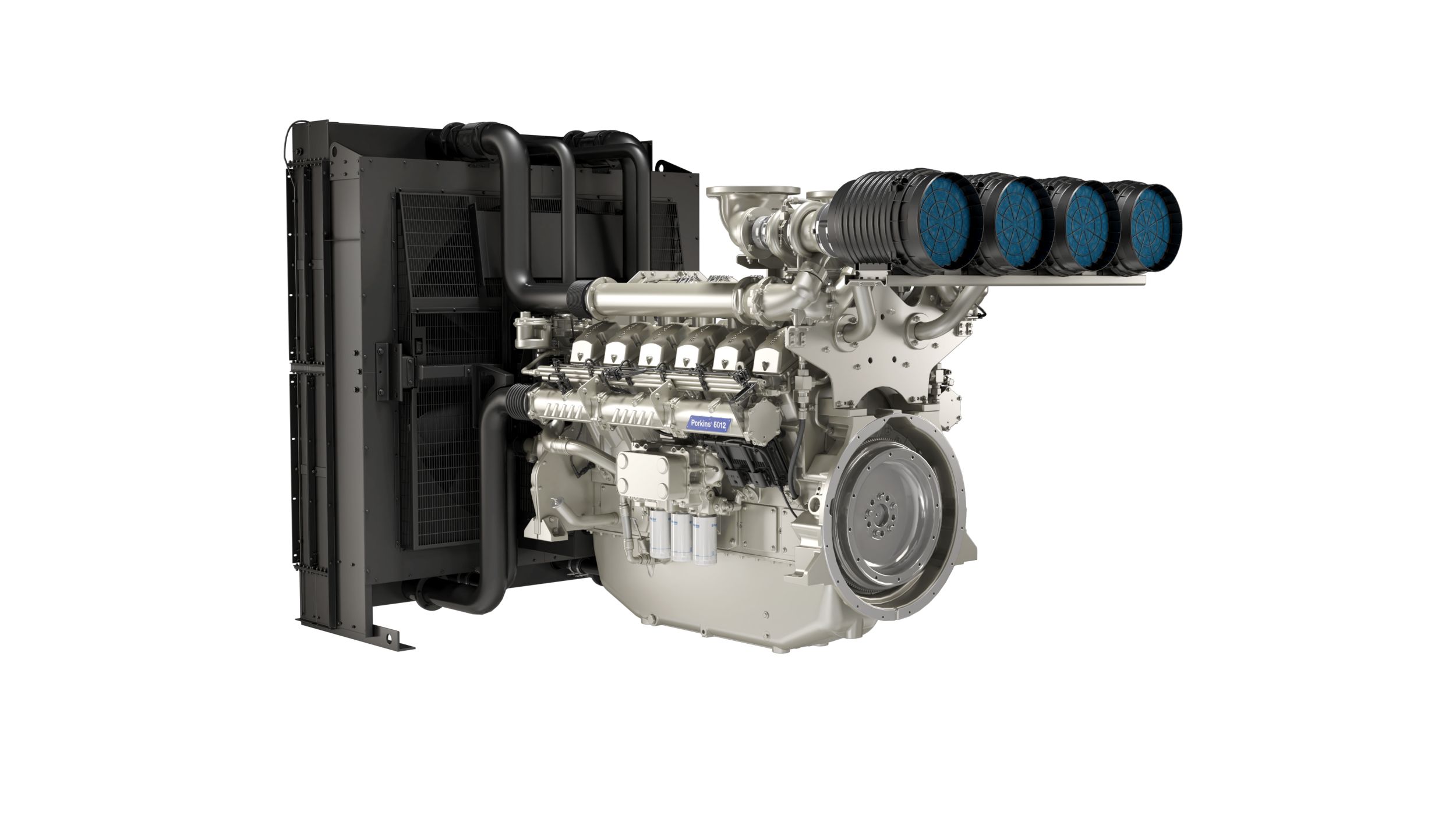

As large-scale infrastructure projects spawn economic development throughout the Middle East, reliable, energy-efficient power is a key element for sustained prosperity.

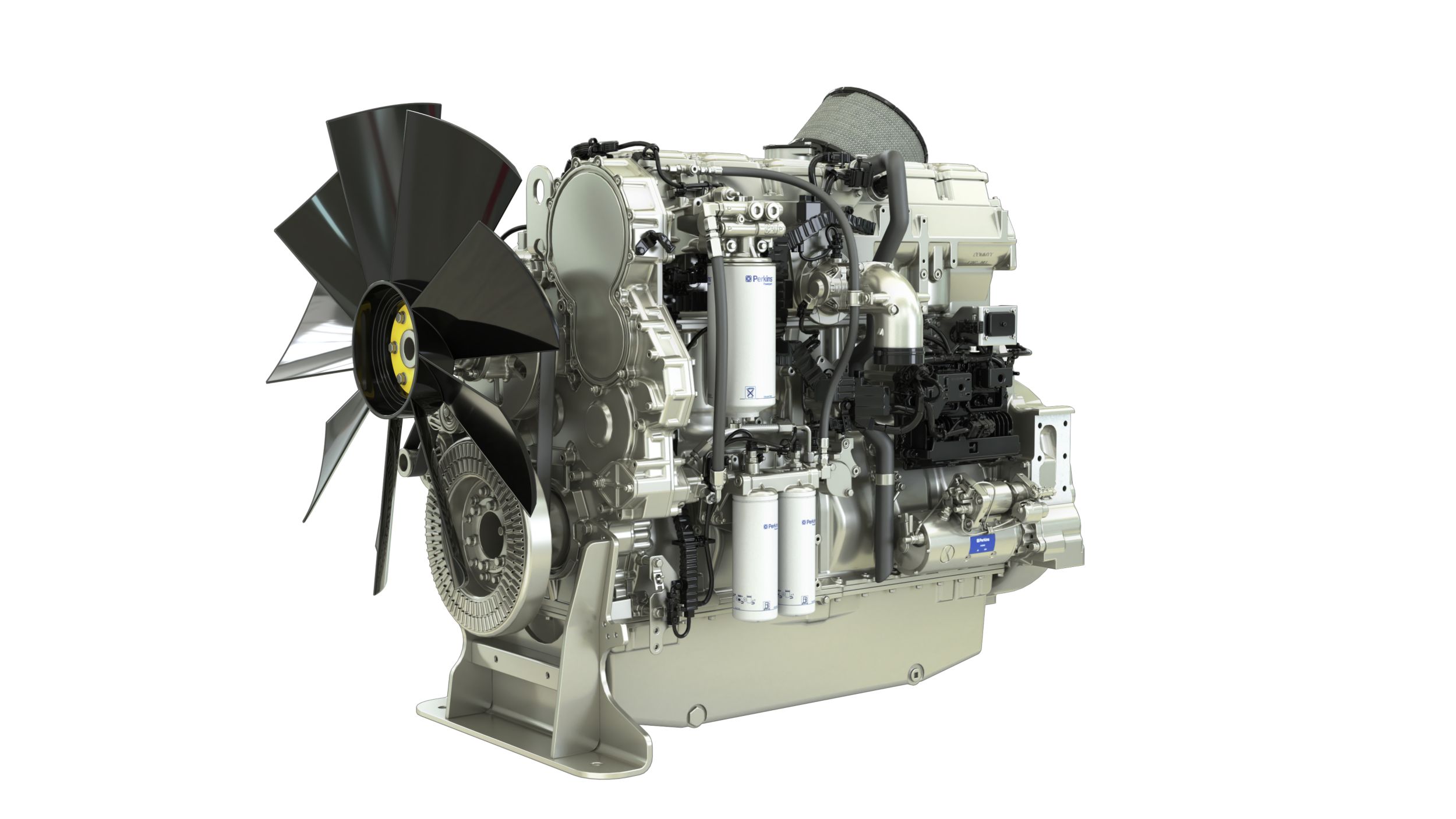

Learn morePerkins introduces CPCBIV+ certified engines designed specifically for the Indian electric power generation industry.

Learn morePerkins marine is set to launch its new Perkins® E44 and E70B auxiliary engines for use on inland waterways, tugs, governmental, fishing and ferry services.

Learn more

If you're ready to receive trusted advice from a Perkins expert, speak to our team today.

Connect with usOur digital magazine with the latest news, interviews and analysis.

Read moreYour regional Perkins Distributor can provide local, on-the-ground engine support.

Learn More