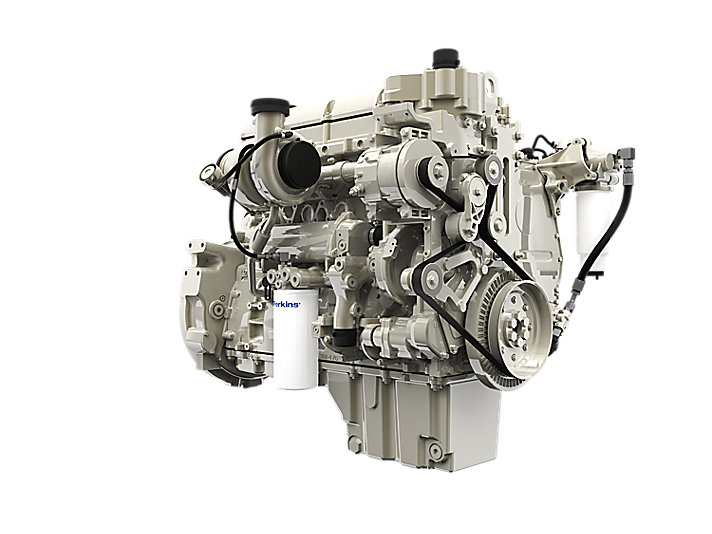

A 6 cylinder, 12.5 litre engine with power up to 430 Nm and peak torque of 2640 Nm to enable engine downsizing.

Optimised design across all systems – fuel, air, electrical, thermal – driving efficiency and lowering total fluid consumption.

Perkins design technology and high-efficiency SCR enable a compact, lightweight aftertreatment with simple installation requirements.

Thermal management designed to provide transparent regeneration, without distraction to the operator or impact to machine performance.

Fully configurable product with factory solutions such as engine mounted aftertreatment and full power units to limit installation complexity.

The 2406J will be available in single label certification for EU Stage V, U.S. EPA Tier 4 Final, Japan 2014 and Korea Tier 4 Final providing global customers a single source solution that streamlines design, installation and service processes.