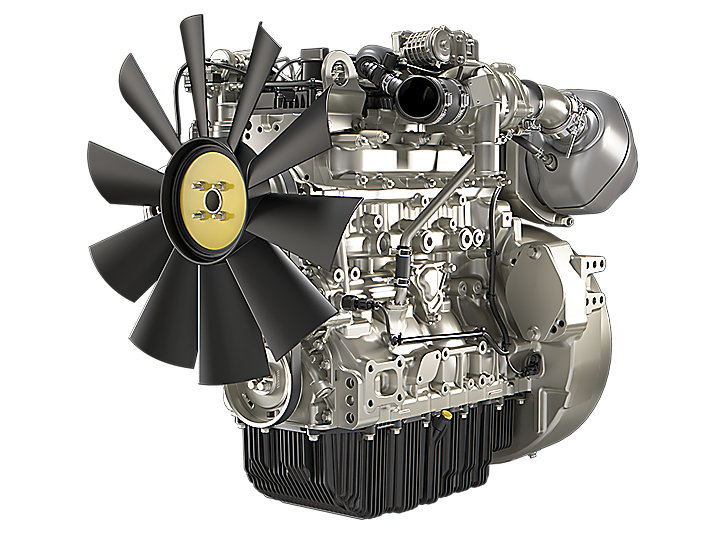

The fuel consumption is optimised to match the operating cycles of a wide range of off-highway applications.Hydraulic tappets, multi-vee belts and 500 hour service intervals enable low cost maintenance.

The engine has been designed using the latest predictive engineering methods, combined with an extensive fieldvalidation program to ensure reliable power in the toughest off-highway conditions.Quality, reliability and consistency are assured. Our facilities worldwide employ the same efficient processes,the same tested and validated components, and the same stringent quality controls wherever your engines aremanufactured.

A modular engine concept allows OEMs to design one engine installation for different regions. This reduces cost and development time for cooling pack, mounting, hydraulic and control interfaces

Perkins recognise that the customer relationship is important to machine manufacturers and we can offer a range of flexible solutions to help provide appropriate support, either to the OEM's network or directly to the machine customer.