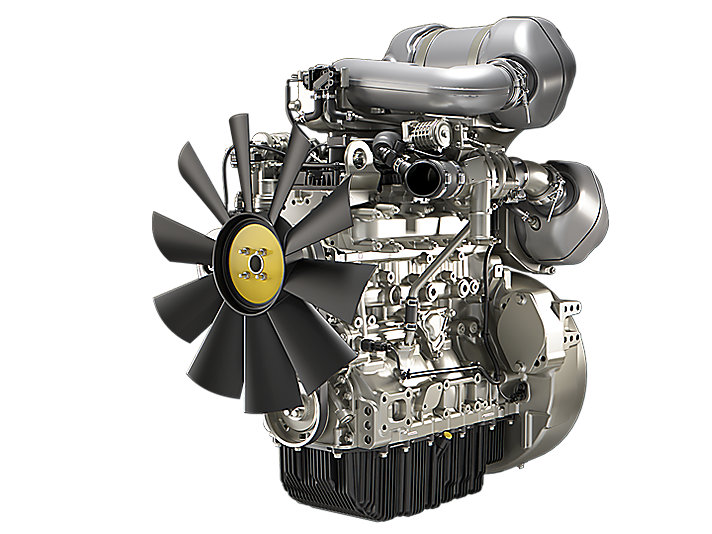

These engines have been designed using predictive engineering methods, with extensive field validation to ensure reliable power in the toughest conditions. Worldwide facilities employ efficient processes, tested and validated components, and stringent quality controls wherever your engines are manufactured.

Fuel consumption is optimised to match the operating cycles of a wide range of off-highway applications. One-year warranties for constant speed engines and two-year warranties for variable speed models, as standard. For further peace of mind, there is also the option to extend the warranty period through Perkins® Platinum Protection.

A modular engine concept allows OEMs to design one engine installation for different regions. This reduces cost and development time for cooling pack, mounting, hydraulic and control interfaces.

A range of flexible solutions available to help provide appropriate support to an OEM’s network or directly to the machine customer. The Perkins logistics operation have the ablility to dispatch parts from stock, reaching the customer within 24 hours helping to maximise the productive life of your engine.