Like you, we believe there is no need for a trade-off between meeting emission standards and delivering on performance. The 1200 Series™ tackles the emissions challenge head-on and gives you improved productivity levels and fuel consumption.

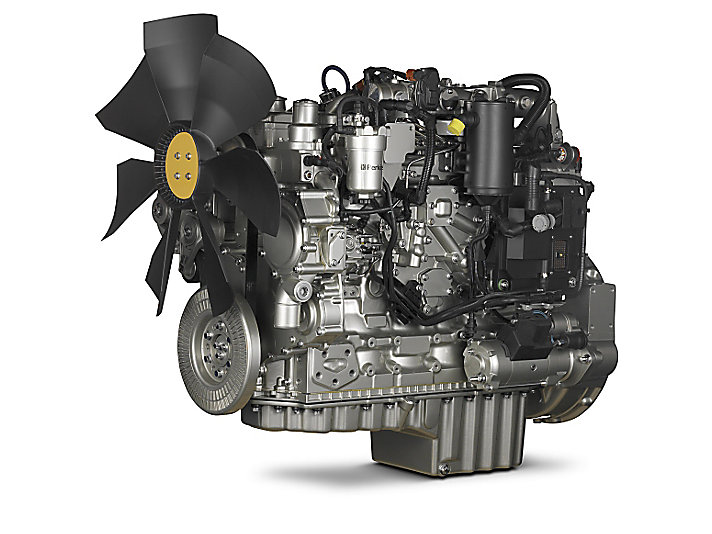

The high power density and excellent torque in our 1206 range gives machine manufacturers the opportunity to use our 6 cylinder engine instead of a larger engine. Downsizing in this way can save you money and create more space to package new aftertreatment units. The 1206 range is an ideal engine solution for large and medium-sized machines for construction, agriculture, materials handling and general industrial applications.

Your needs are our top priority, which is why we provide tailored technology solutions. Working closely with OEMs, we have developed the 1206 range with hundreds of variables so that it easily fits into your machine

Our 1206 range engines come with two year warranties as standard and and can also be supported by extended service contracts

Building on more than 80 years of experience, the 1200 Series benefits from our engineering experience and heritage. Its improved productivity and fuel consumption reduces the total cost of ownership.