Total Power Range

| Gross Mechanical Output | 623-821 kWm 623-821 kWm |

| Typical Electrical Output | 706 - 938 kVA (565 - 750 kWe) 706 - 938 kVA (565 - 750 kWe) |

| Rated Speed | 1500/1800 rpm 1500/1800 rpm |

Key Specs

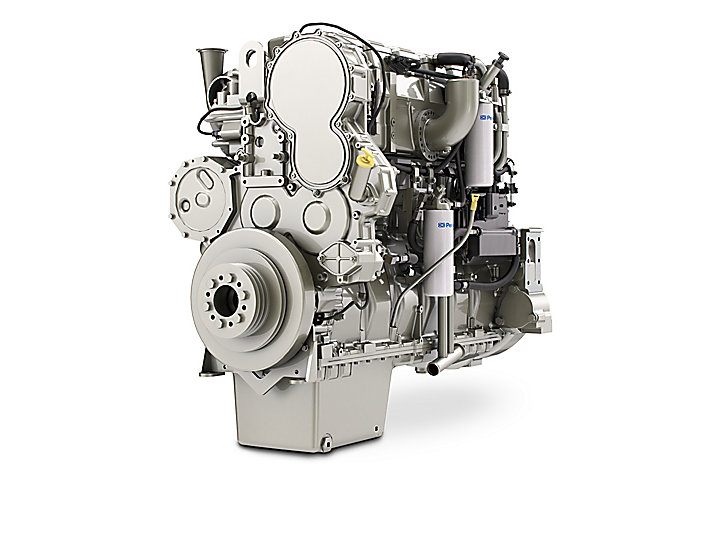

The Perkins 2800 Series is a family of well-proven 6 cylinder, 18 litre in-line diesel engines, designed to address today’s uncompromising demands within the power generation industry with particular aim at the standby market sector. Developed from a proven heavy-duty industrial base, the engine offers superior performance and reliability. The 2806A-E18TTAG is a series turbocharged and air-to-air charge cooled, 6 cylinder diesel engine of 18 litres capacity.

Its premium features provide economic and durable operation, low gaseous emissions and advanced overall performance and reliability.

• Low emissions result from electronic control of fuel injected

• High compression ratios also ensure clean rapid starting in all conditions

• Perkins global product support is designed to enhance the customer experience of owning a Perkins powered machine. We deliver this through the quality of our distribution network, extensive global coverage and a range of Perkins supported OEM partnership options. So whether you are an end-user or an equipment manufacturer our engine expertise is essential to your success

• Designed to provide excellent service access for ease of maintenance

• The availability of a low emissions specification allows minimum environmental impact through operation, and complies with US EPA emissions legislation. The standard specification model provides superior fuel consumption which maximises engine efficiency

| Gross Mechanical Output | 623-821 kWm 623-821 kWm |

| Typical Electrical Output | 706 - 938 kVA (565 - 750 kWe) 706 - 938 kVA (565 - 750 kWe) |

| Rated Speed | 1500/1800 rpm 1500/1800 rpm |

| Emissions | Fuel Optimised Fuel Optimised |

| Prime | 706-770 kVA 706-770 kVA |

| Standby | 780-850 kVA 780-850 kVA |

| Prime | 642-680 kWe 642-680 kWe |

| Standby | 710-750 kWe 710-750 kWe |

| Number of Cylinders | 6 vertical inline 6 vertical inline |

| Bore | 5.71 in 145 mm |

| Stroke | 7.2 in 183 mm |

| Displacement | 1104.53 in³ 18.1 l |

| Compression Ratio | 14:01 14:01 |

| Aspiration | Parallel turbocharged and air-to-air charge cooled Parallel turbocharged and air-to-air charge cooled |

| Combustion System | Direct injection Direct injection |

| Rotation from Flywheel End | Anti-clockwise Anti-clockwise |

| Cooling System | Liquid Liquid |

| Aftertreatment | - - |

| Typical Alternator Efficiency | 95% 95% |

| Switchable | Yes Yes |

| Length | 100 in 2538 mm |

| Width | 67 in 1691 mm |

| Height | 84 in 2126 mm |

| Dry Weight | 5206 lb 2361 kg |

| Note 1 | *Final dimensions dependent on selected options *Final dimensions dependent on selected options |

| Prime Power | Power available at variable load in lieu of a main power network. Overload of 10% is permitted for one hour in every 12 hours of operation. Power available at variable load in lieu of a main power network. Overload of 10% is permitted for one hour in every 12 hours of operation. |

| Standby Power | Power available at variable load in the event of a main power network failure. No overload is permitted. Power available at variable load in the event of a main power network failure. No overload is permitted. |

Use the comparison tool to compare detailed specs of Perkins and competitor models.

Compare All Models