We have helped power success in the biggest machines that drive the most demanding industries worldwide for decades. Leading with innovative designs and technologies to get the most out of every engine we develop, our customers know that when their machine is powered by Perkins, they know they'll get the job done. Perkins engines are trusted to power over 3 million machines across the world.

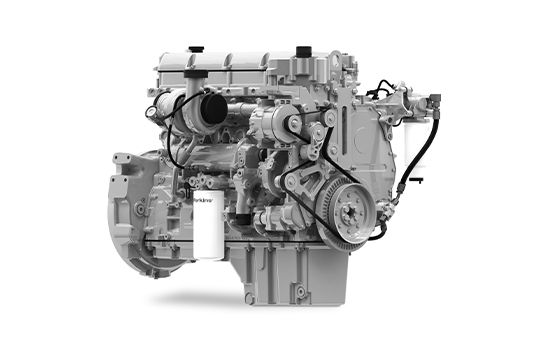

With proven reliability, compact package size, low maintenance costs and low emissions, Perkins engines have become the natural choice for any OEM looking to build high-end excavators, loaders, compactors and earthmoving equipment

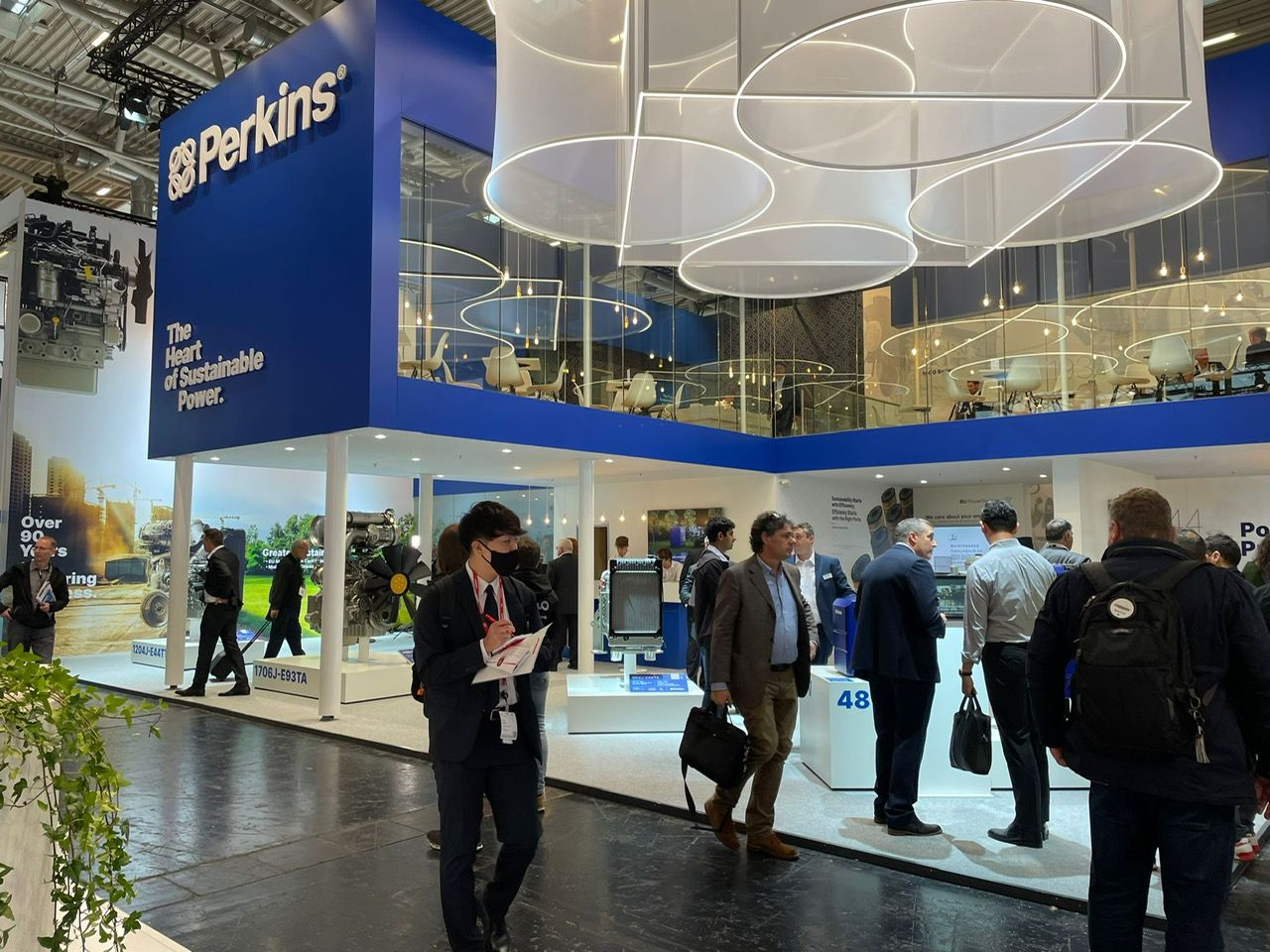

Driven by over 90 years of continual innovation, Perkins leads the field in the design and manufacture of high-end performance diesel engines.

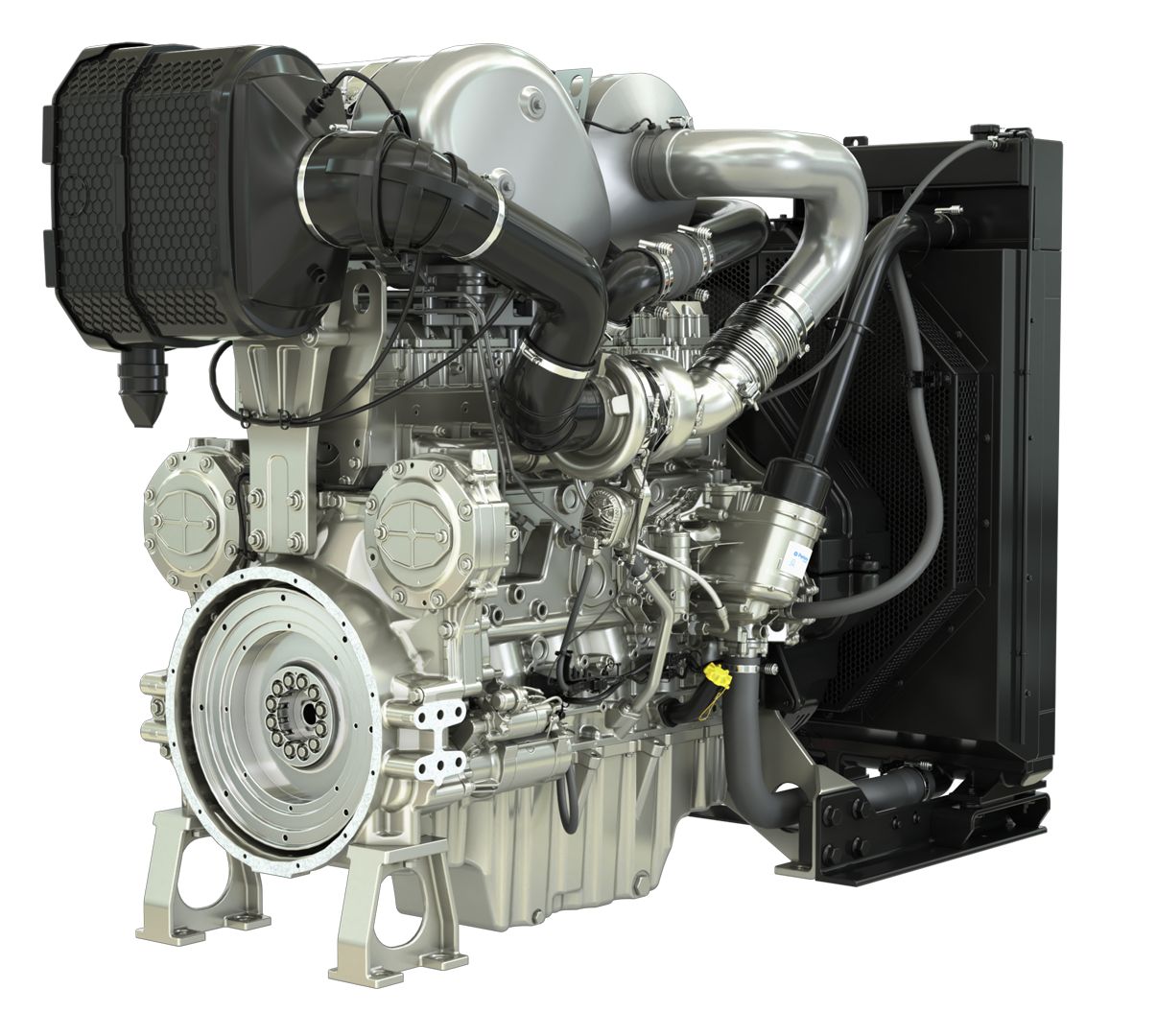

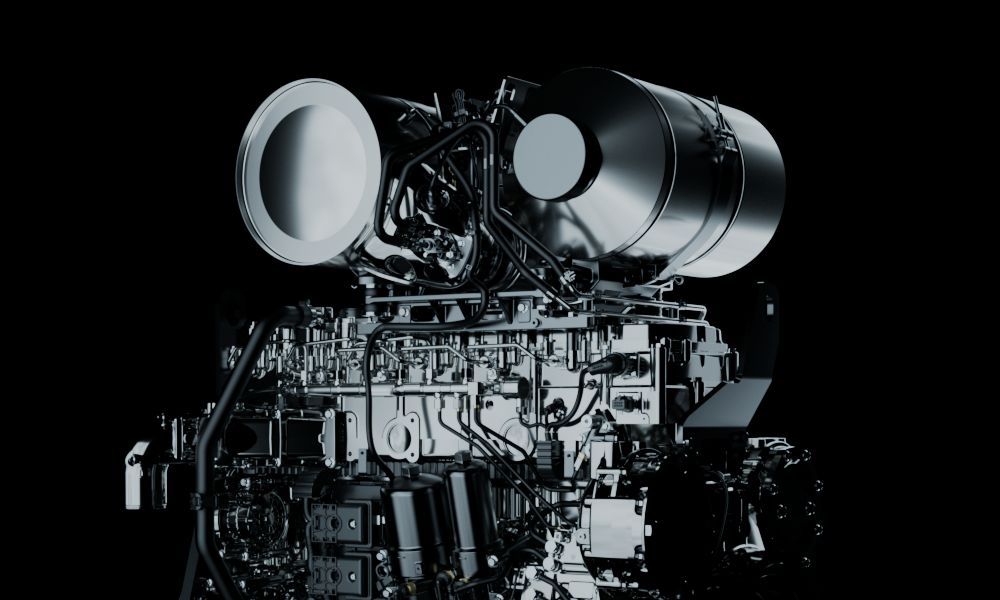

With full industrial engines from 0.5 to 18 litres , Perkins engines power more than five thousand different applications throughout the world. Whether it's to power an excavator, a loader, or a compactor, we have an engine to meet your needs, ranging from the ultra-compact 400 Series to our powerful 2800 Series to keep operations at peak efficiency.

6 cylinder

18.1 litre

429 - 597 kW (575 - 800 hp)

6 cylinder

12.9 litre

340 - 515 kW (456 - 690 hp)

6 cylinder

15.2 litre

354 - 444 kW (475 - 595 hp)

6 cylinder

12.5 litre

340 - 430 kW (456 - 577 hp)

Ranging from 8 to 800hp (6 to 600kW), Perkins engines cater to all machine sizes and meet the most stringent emission standards, including EU Stage V and U.S. EPA Tier 4 Final. Designed specifically for off-highway operating cycles and tested in real-world conditions, Perkins engines offer straightforward installation, dependable performance, and optimised fuel consumption to keep operating costs under control and productivity at its peak.

Click here to download our Engine Ratings Guide

Through using the latest technologies and best in engineering expertise, our engines are designed to:

For most OEMs, the biggest engine challenge is establishing the right fit and getting the machine to market quickly and cost-effectively. At Perkins we work with you to streamline this process. Whether you're looking to power a backhoe loader, a soil compactor or a motor grader – we'll make integration seamless.

To support the industry navigate the energy transition Perkins has evolved to deliver smarter solutions that advance sustainable power. Leveraging our expertise in the off-highway sector, we help customers navigate the energy transition with intelligent, sustainable power solutions and cutting-edge low emission power systems including batteries, hybrid engines, and optimised engines designed for use with renewable fuels.

Wacker Neuson’s new EW100 10-ton-mobile excavator has been developed in close cooperation with customers, attachment manufacturers and companies across the construction industry.

Learn MoreThe smaller DV45 Dual View Dumper allows users to navigate smaller worksites with greater ease and safety, without compromising on the power necessary to move heavy loads.

Learn MorePerkins applied its deep understanding of engine technology to help Liechtenstein manufacturer Kaiser develop a new generation of Stage V walking excavators that delivers on emissions, efficiency and mobility.

Learn MoreThe Perkins brand, which is synonymous with quality, has quickly become the preferred power solution for China’s high-end excavator manufacturers. Perkins distributor, Elco Power continues to be instrumental in shaping this success.

Learn More

Stay updated with the latest news from Perkins

Join Perkins at bauma 2025, the world's leading trade fair for construction and mining machinery, to explore our advancements in power technology designed to elevate your machinery offerings by combining cutting-edge technology with our deep knowledge and industry expertise.

Read moreAt Perkins, we are committed to investing in optimised diesel technologies to ensure our customers receive the best in performance and efficiency.

Read moreIn the world of off-highway equipment, the quest for more power and efficiency never stops. Manufacturers are constantly seeking ways to enhance performance while maintaining or even reducing the size of their machinery.

Read moreIn today's world, there is an increasing emphasis to reduce greenhouse gas emissions. As a result, renewable fuels have emerged as a promising alternative to traditional fossil fuels.

Read moreOur digital magazine with the latest news, interviews and analysis.

Read more

Speak directly with the experts at Perkins and learn how our customised solutions can power your machines and support your business. Whether you need reliable engines, or you want to discuss which engines can power your machines, or how to navigate the energy transition - our team is ready to help drive your success. Contact us today.

false

*See your engine's Operation Maintenance Manual for specific biodiesel limits on your engine