Geotec Bohrtechnik GmbH of Nordkirchen, Germany has been a leading producer of high-quality vertical drilling rigs for more than 25 years and their Rotomax products support all of these drilling technologies and applications.

Because they often are used under difficult conditions in remote locations, or in projects with strict time constraints, efficiency and reliability are key requirements for every component used in Rotomax rigs.

Engine

Read profile

Engine info

Product overview

Gallery

Related case studies

There's nothing boring about Geotec's drill rigs

Drilling into the earth may seem like a simple process, but in reality there are many different techniques available to meet a broad range of application requirements. Modern vertical drill rigs are used for near-surface geothermal energy extraction, geotechnical engineering, mining and well construction, using techniques including dry drilling with casing, cable percussion drilling with casing, suction drilling and core drilling plus drilling with endless or hollow stem augers.

Geotec Bohrtechnik GmbH of Nordkirchen, Germany has been a leading producer of high-quality vertical drilling rigs for more than 25 years and their Rotomax products support all of these drilling technologies and applications. Because they often are used under difficult conditions in remote locations, or in projects with strict time constraints, efficiency and reliability are key requirements for every component used in Rotomax rigs.

800 different Perkins powered machines

Norbert Zumholz, managing director of Geotec Bohrtechnik explains why they have used Perkins® 1200 Series engines in more than 800 different machine models over the years.

“For our drilling equipment, we need consistently reliable, robust and powerful engines, with as little maintenance as possible. In this respect, we are very satisfied with the performance of the Perkins 1200 Series.”

Reliable 24/7 operation

A good example of both the flexibility of Rotomax drill rigs and the reliability of Perkins 1200 Series engines is provided by a recent project supporting construction of a feeder tunnel from Munich to the Brenner near Kufstein in Tyrol. The surface location was 890 m above sea level on the German/Austrian border, but the actual drilling was done in a location 160 m below ground level.

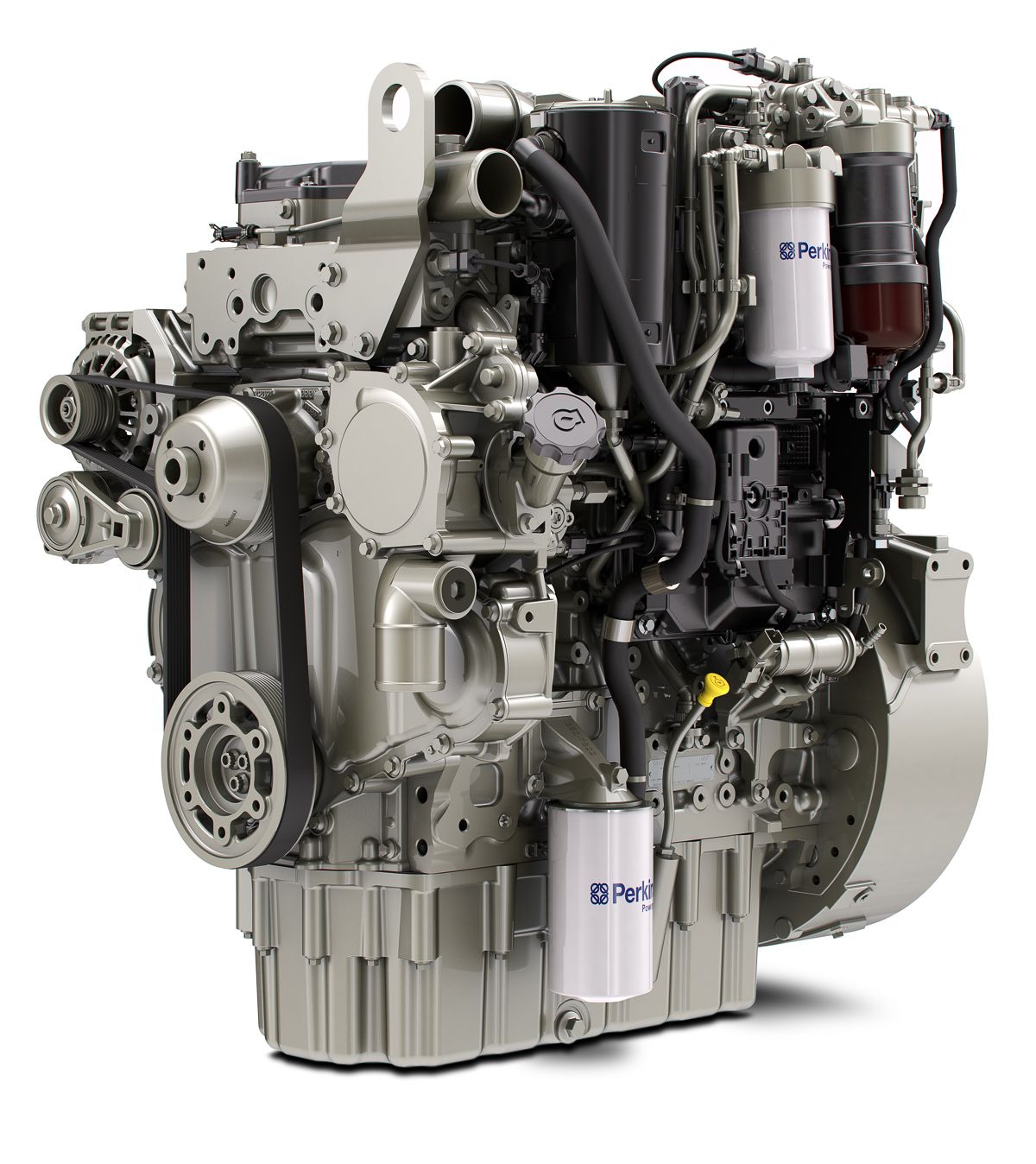

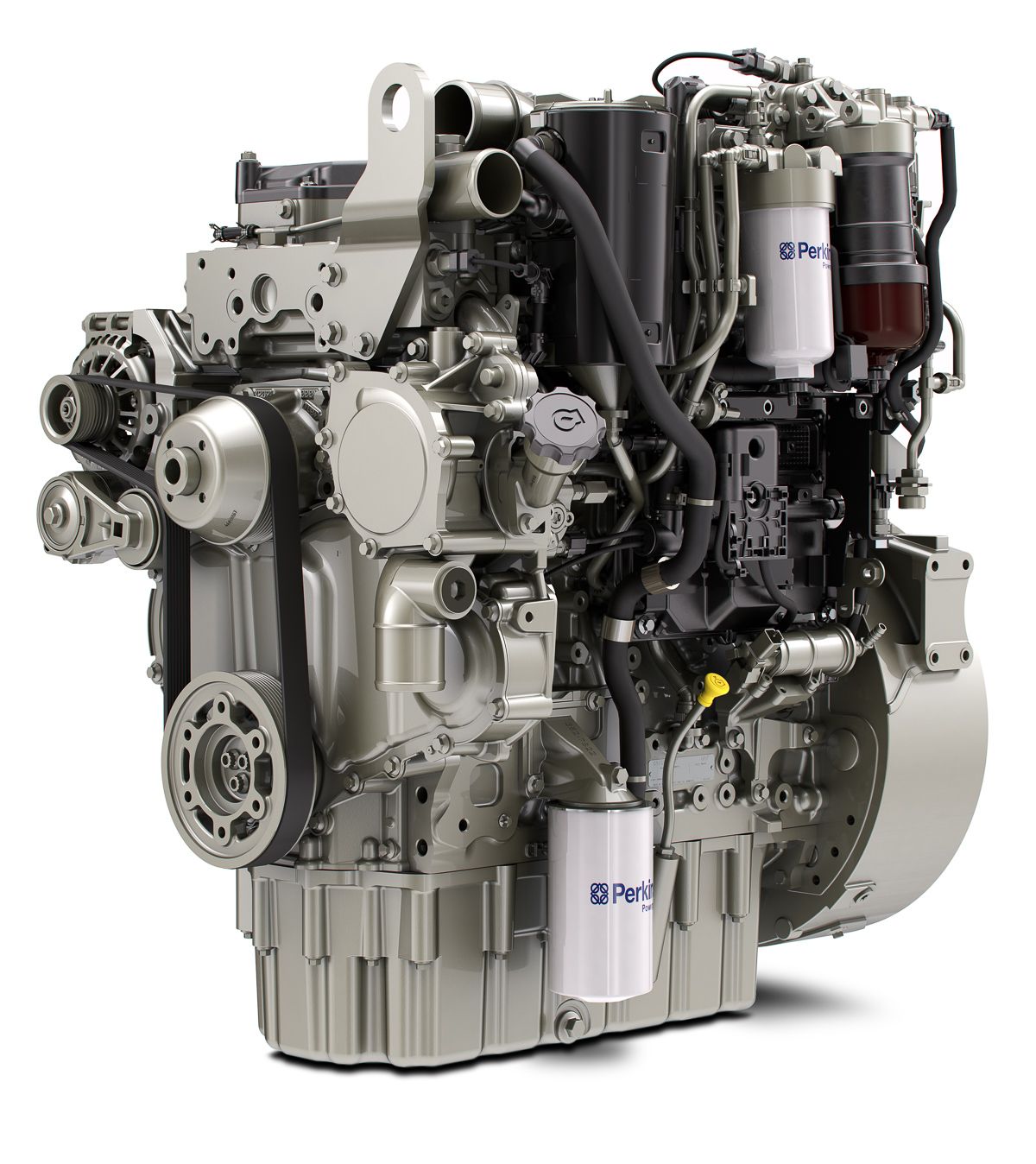

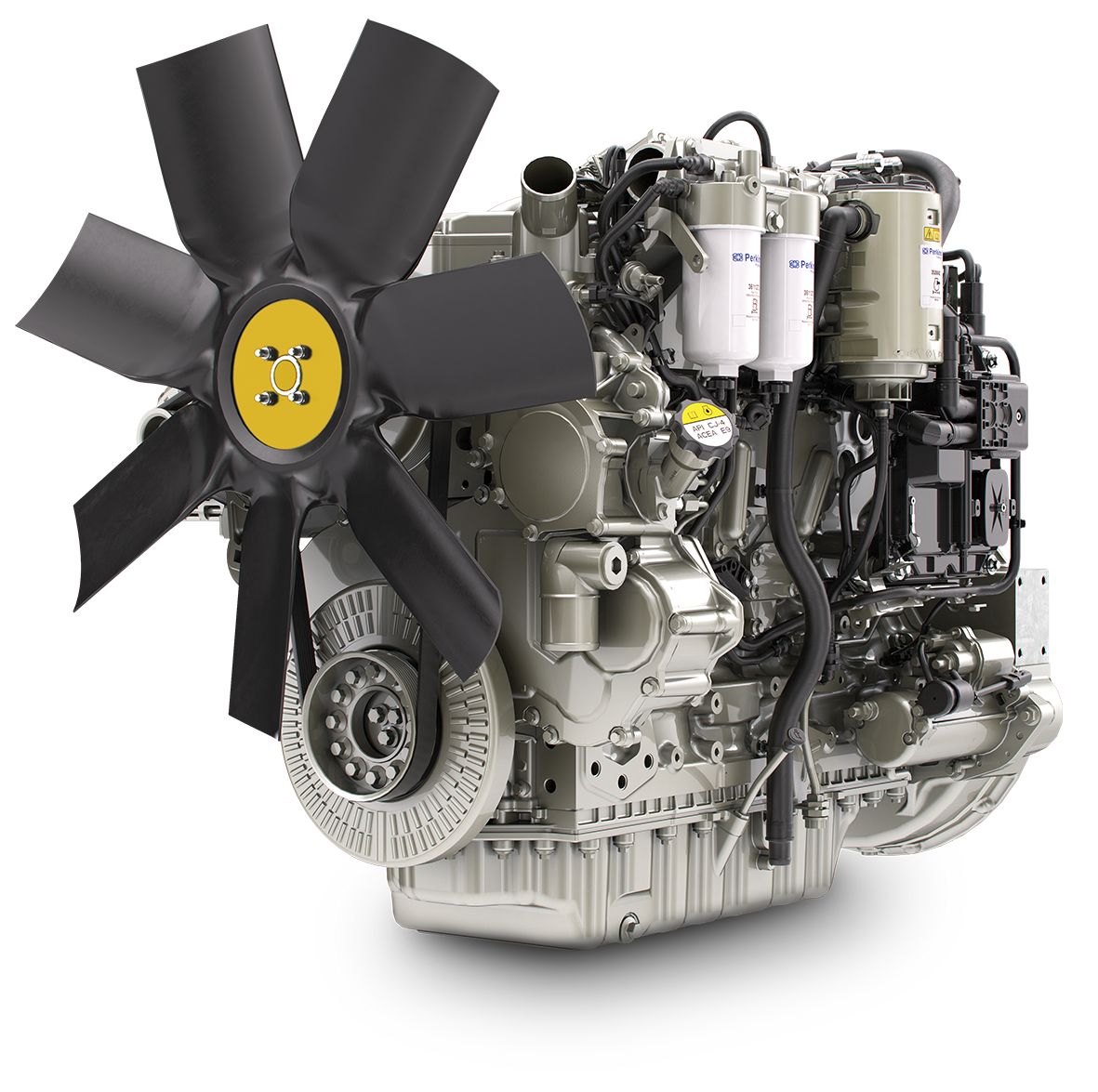

The Geotec Rotomax XL-B rig used to drill the geotechnical exploration bores is powered by a 4-cylinder diesel that meets EU Stage V emission standards and produces 140 kW and 825 Nm of torque. The 1204J-E44TTA powered the Rotomax XL-B 24 hours a day continuously for six weeks to complete the project on-time.

A machine for every application

The same Perkins® 1204J-E44TTA powers the Geotec Rotomax XL-GT used in a geothermal boring project for a Welch housing estate that included several solar plants. Again, the 1204 engine – the 4-cylinder option of the 1200 Series – provides Geotec with a complete drive solution that meets the latest emission standards with robust technology delivering reliable performance.

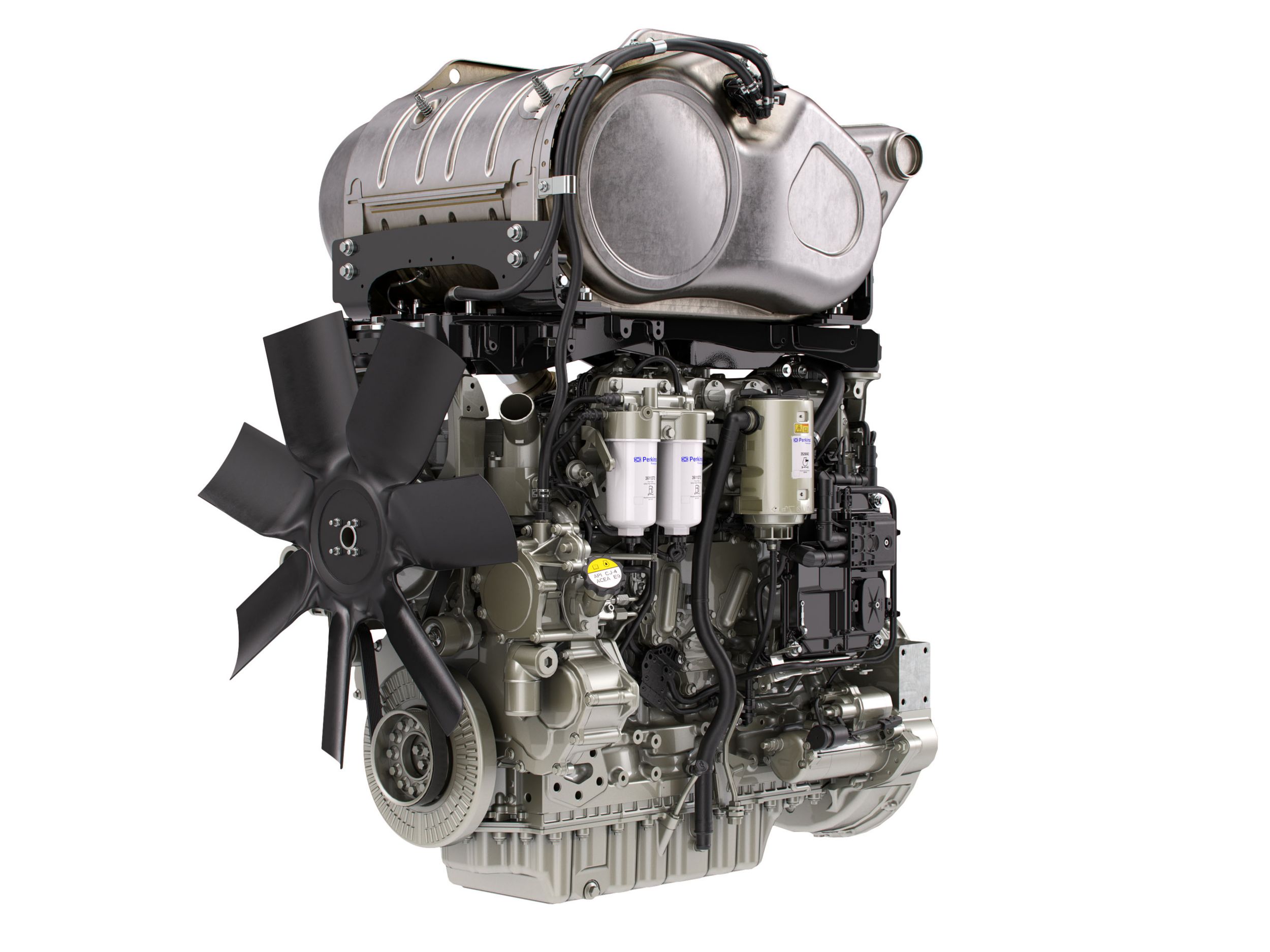

The larger Rotomax XL-GTCi rig was used to drill a service water well for a horse stud farm in Wales using a double-head drill. Weighing up to 18 t, the Rotomax XL-GTCi stores drill pipe in an on-board magazine and moves to the drill site on rubber tracks after unloading from its tandem transport trailer.

It’s powered by a Perkins® 1206J-E70TTA engine – the 6-cylinder option of the 1200 Series – that produces 205 kW and 1257 Nm of torque. Like the 4-cylinder versions of the 1200 Series, the 1206J-E70TTA meets Stage V emission standards.

Dependable service and support

Reliable engines require reliable service and support, and for Geotec that comes from their Perkins authorised distributor, BU Power Systems. “We benefit from good advice – no matter whether it’s about choosing the right engine for our drilling equipment, to service and spare parts availability. BU Power Systems, supports us reliably and competently at all times,” says Norbert.

“For our drilling equipment, we need consistently reliable, robust and powerful engines, with as little maintenance as possible. In this respect, we are very satisfied with the performance of the Perkins® 1200 Series.”

Norbert Zumholz, managing director of Geotec Bohrtechnik

Services

Discover more about some of the additional services Perkins can offer you.