WINTER Markiertechnik GmbH of Wilnsdorf-Niederdielfen, Germany is a leading supplier of the specialised equipment required to apply and, when necessary, remove structural and pavement markings from roadways, airports and other facilities.

WINTER’s product portfolio includes machines for nearly every marking technology and application including structural markings, thick-film markings and spray applications using air spray, airless or hot-spray processes.

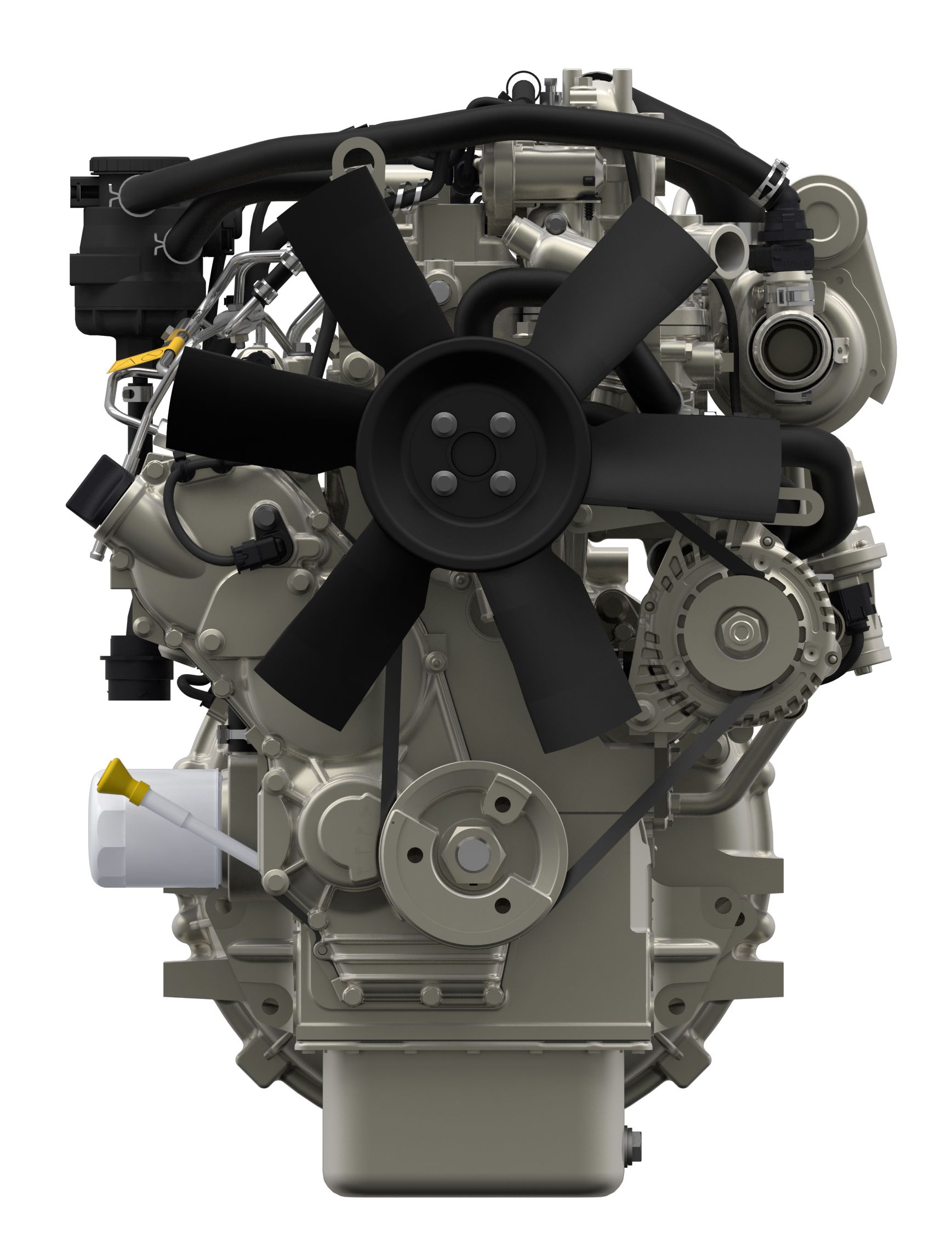

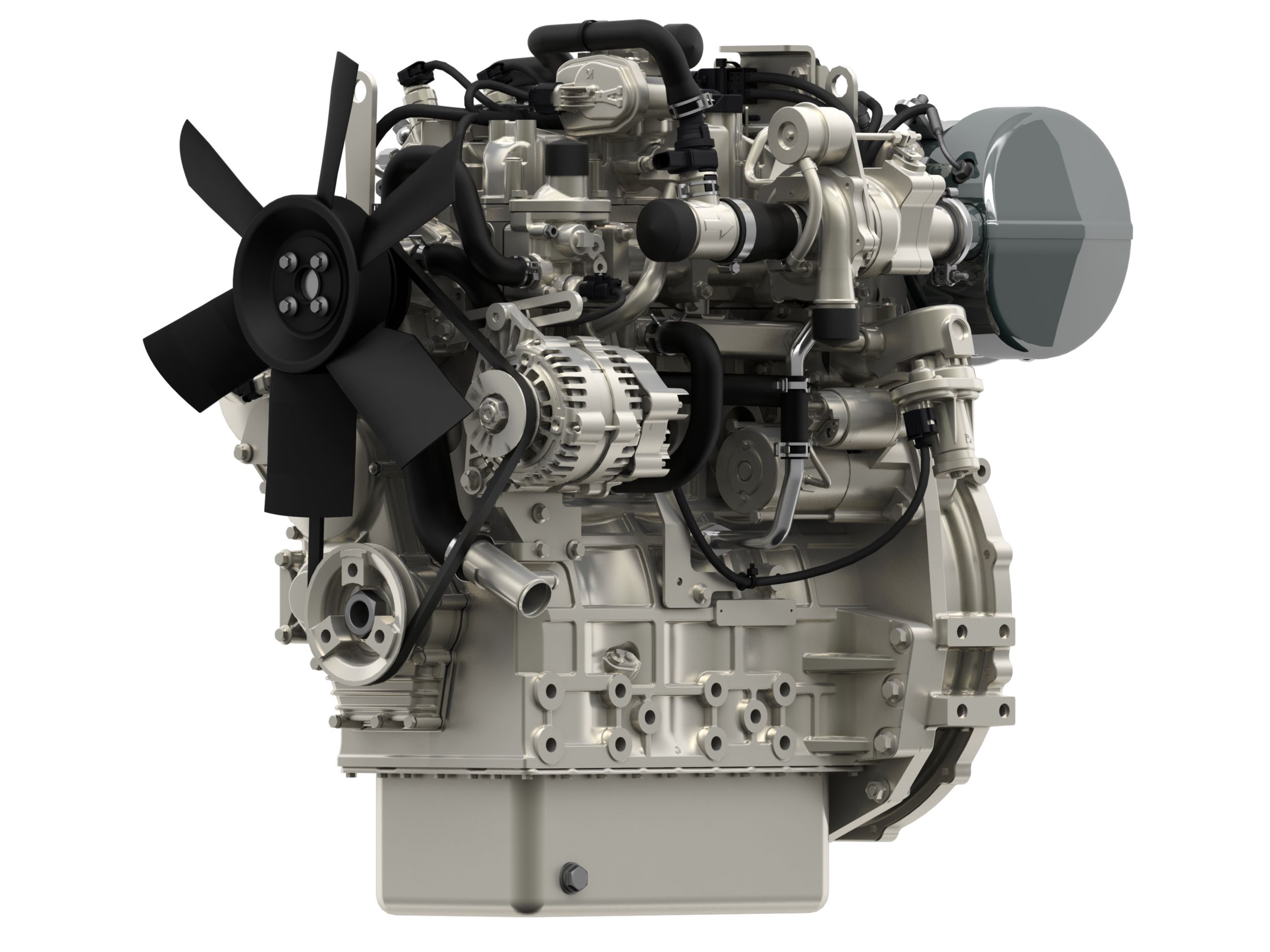

Engine

Read profile

Engine info

Product overview

Gallery

Related case studies

Making a mark

Like most technologies today, pavement marking has evolved from a simple paint spraying operation into an array of specialised processes applying everything from rolls of tape to thick, textured thermoplastics in addition to the traditional paint. WINTER Markiertechnik GmbH of Wilnsdorf-Niederdielfen, Germany is a leading supplier of the specialised equipment required to apply and, when necessary, remove structural and pavement markings from roadways, airports and other facilities.

WINTER’s product portfolio includes machines for nearly every marking technology and application including structural markings, thick-film markings and spray applications using air spray, airless or hot-spray processes. They also produce roadway dryers, demarking cutters, thermoplastic pre-heaters and bead spreaders plus hand-held, self-propelled and truck-mounted application systems.

Efficient, modular machines

Their popular W 351 GTLR series of machines features an innovative, modular design that enables one machine to apply a whole range of different marking technologies. An integrated operator station and power unit can be quickly mated with a range of different application systems to efficiently and economically apply anything from paint to the thickest, textured thermoplastics.

Quiet, reliable Perkins power

WINTER powers the W 351 series with a 4-cylinder Perkins® 404J-E22TA, EU Stage V 2.2 litre engine producing 55 kW (74 hp) and 279 Nm of torque at only 1600 rpm. In addition to its low operating costs, the 404J-E22TA also offers extremely low noise levels which can reduce operator fatigue and expand working time in noise-sensitive environments.

A flexible, user-friendly solution

WINTER’s team leader for sales marking technology, Lisa Parczanny explains the decision. “Easy maintenance, low fuel consumption and a maintenance-free aftertreatment system makes the 400 Series engine particularly user-friendly for us. A special feature of the W 351 is the modular design of the machine. Different application requirements can be processed with different front carriages. The engine fits harmoniously into the machine design of the W 351 series and is suitable for a wide range of application requirements.”

“In addition, the ATMOS PDP series compressors can be flexibly configured. Depending on the location and the customer’s requirements, there are a wide variety of options. With the Perkins 400 Series engine, we have chosen a motor that can respond flexibly to these wishes and that runs robustly and reliably.”

“Easy maintenance, low fuel consumption and a maintenance-free aftertreatment system makes the 400 Series engine particularly user-friendly for us.”

Lisa Parczanny team leader, sales marking technolog

Services

Discover more about some of the additional services Perkins can offer you.