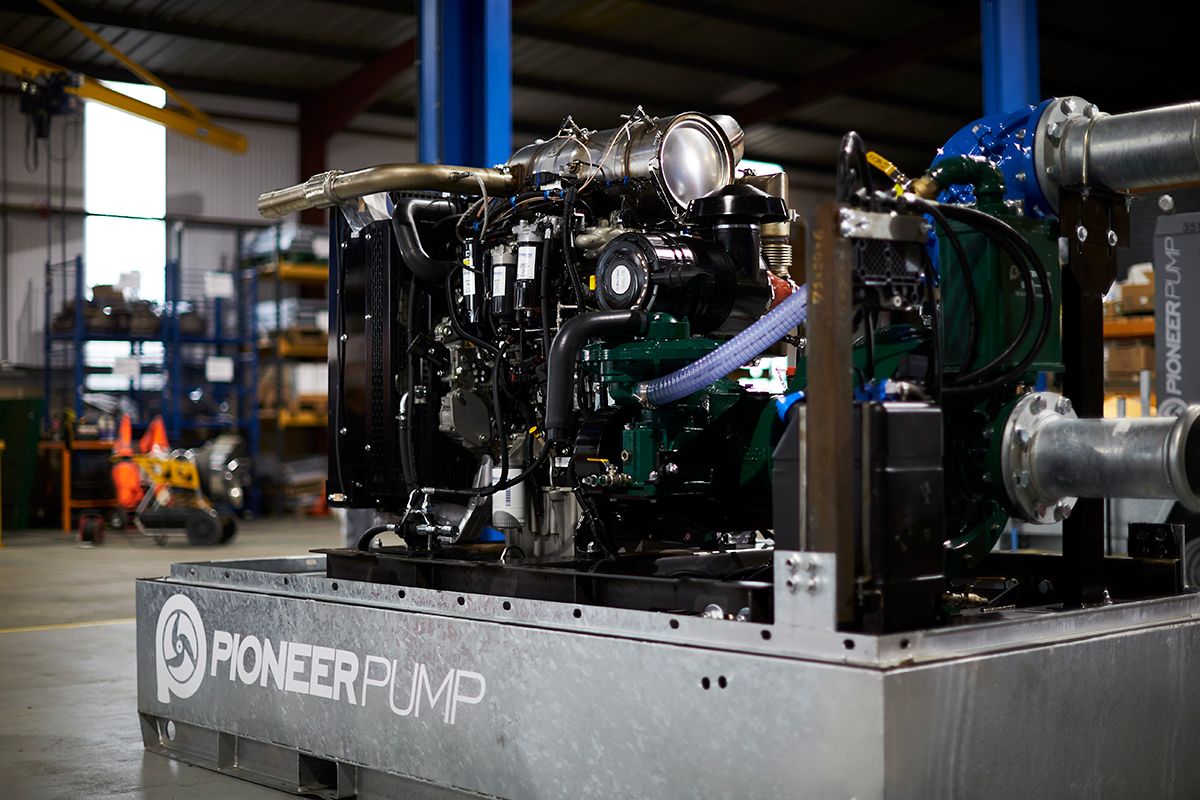

High-pressure and high-volume units like Pioneer Pump’s 8” to 14” Pioneer Prime diesel- driven packages act as the workhorse for a wide range of applications. Powered by a Perkins® 1706J-E93TA engine, these pumps dewater and transfer water in mines, quarries and oil fields. They also assist with municipal bypass and storm water management after major disasters. A brand of Franklin Electric, Pioneer Pump was established in 1998 and is a global leader in the centrifugal pumps industry.

Engine

Read profile

Engine info

Product overview

Gallery

Related case studies

Transferring water and wastewater from point A to B is often one of the first critical steps that must be completed before a job can truly get underway. Having a reliable pump that you can install, operate and trust to meet your demands cannot be understated.

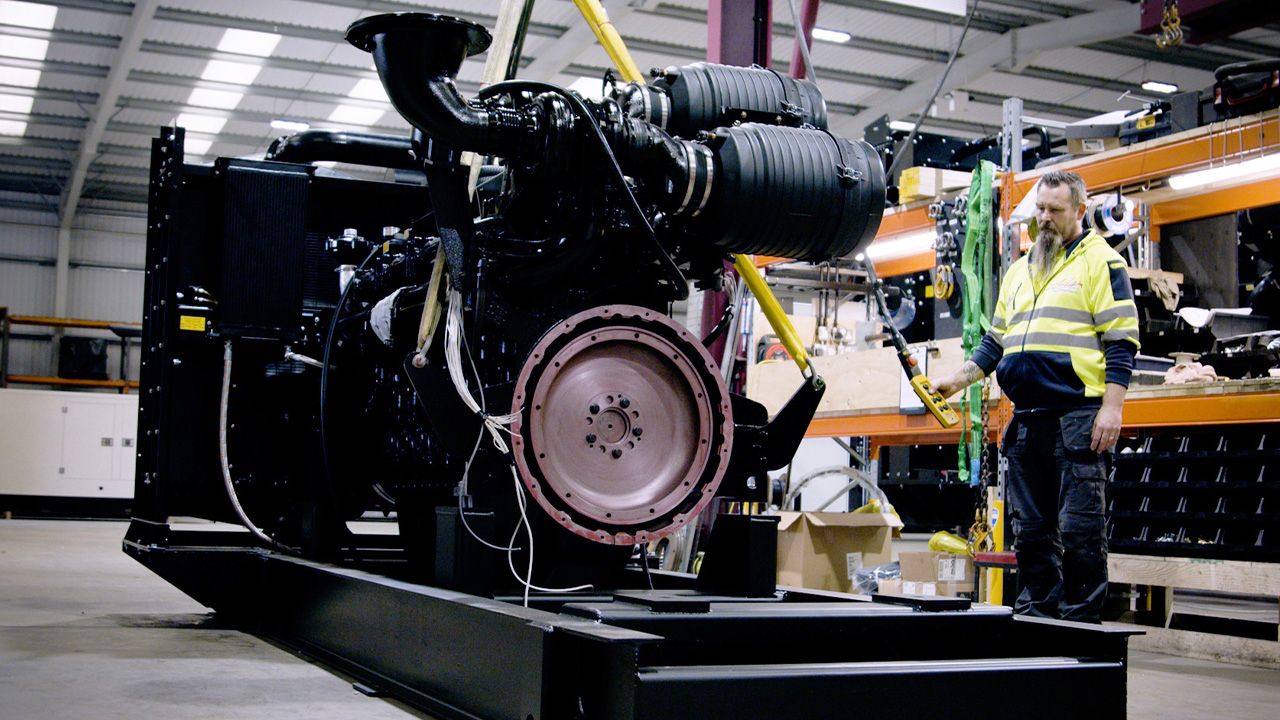

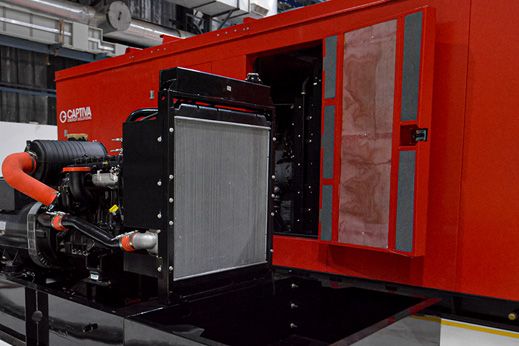

High-pressure and high-volume units like Pioneer Pump’s 8” to 14” Pioneer Prime diesel-driven packages act as the workhorse for a wide range of applications. Powered by a Perkins® 1706J-E93TA engine, these pumps dewater and transfer water in mines, quarries and oil fields. They also assist with municipal bypass and storm water management after major disasters.

A brand of Franklin Electric, Pioneer Pump was established in 1998 and is a global leader in the centrifugal pumps industry. The company selected Perkins for the last decade to support its portable diesel-driven trailer and skid-mounted packages with reliable Perkins power.

Smaller size, full horsepower

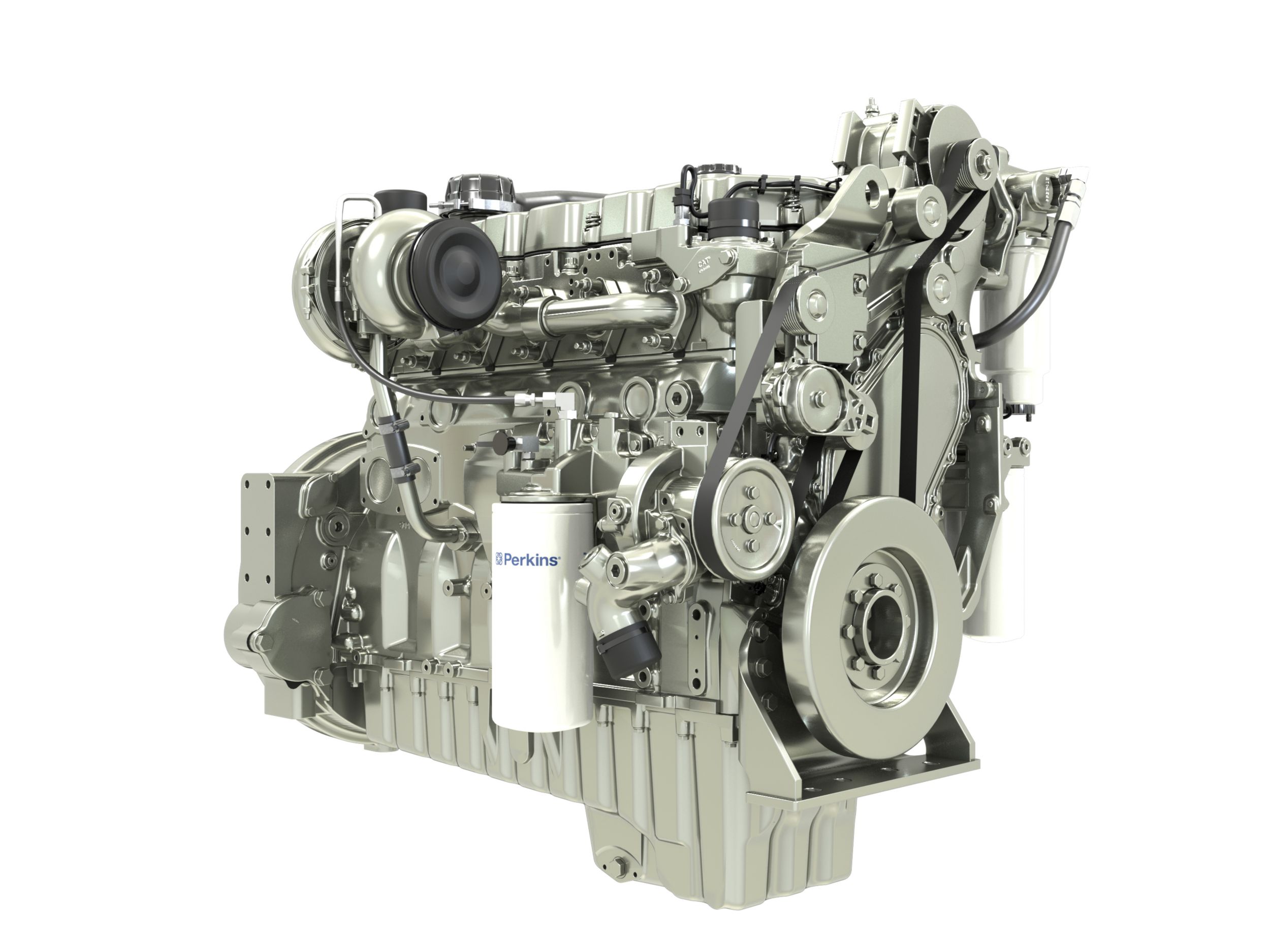

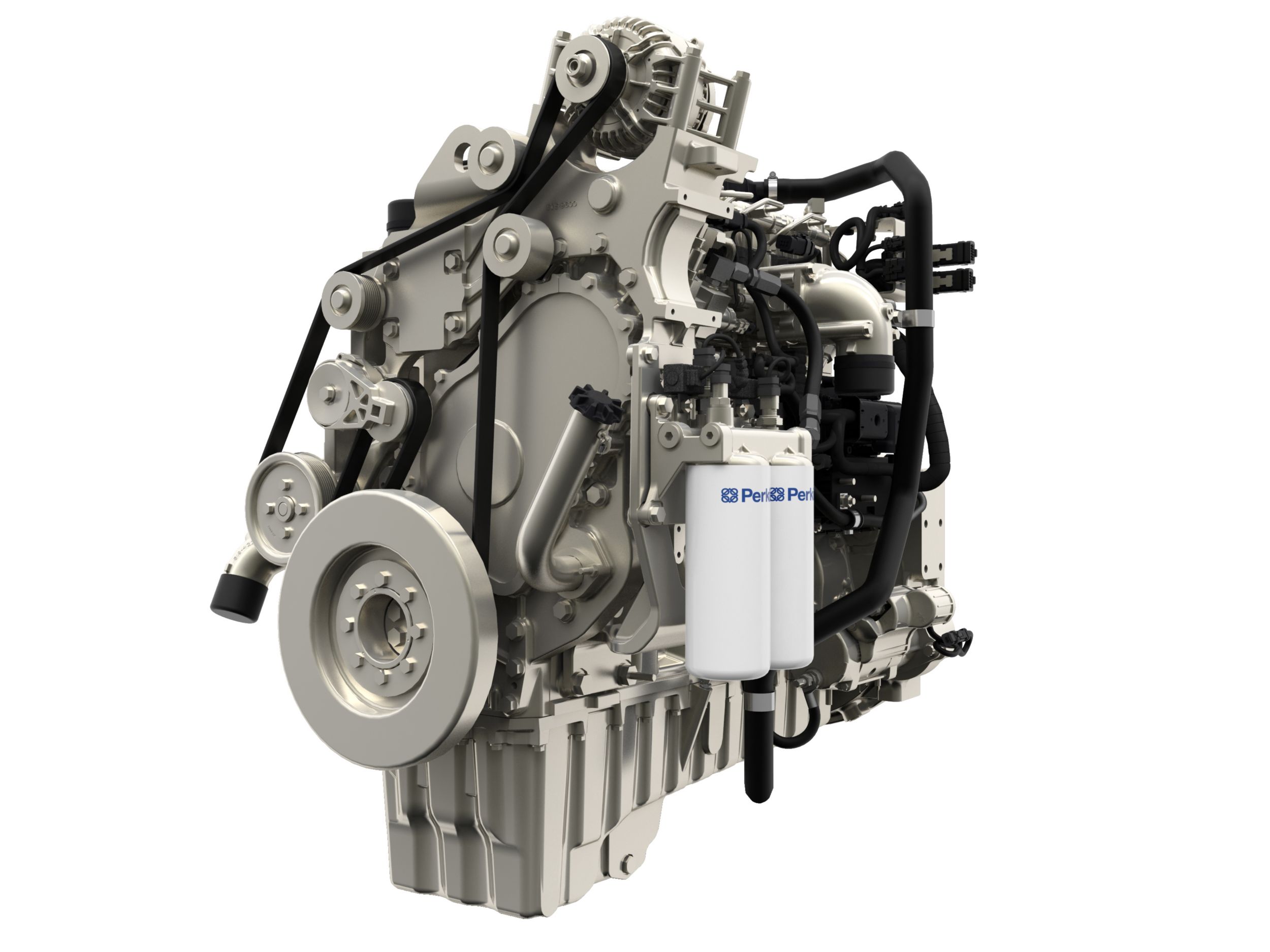

The six-cylinder, turbocharged Perkins 1706J-E93TA engine brings a max of 456 horsepower. Extremely power dense, the engine offers optimum fuel consumption and low heat rejection for reduced overall operating costs.

Even the engine’s size adds to its benefit. Most other competing engines at this horsepower are bigger, requiring a larger, more expensive platform for placement on DOT-compliant trailers, skids and enclosures. That’s not the case with the Perkins 1706J-E93TA.

“With the smaller footprint for the horsepower from Perkins, we can fit a smaller, less expensive platform. That’s a real cost savings for the customer,” explained Chris Nelson, director of sales for Franklin Electric.

Supreme efficiency and leading lifetime value

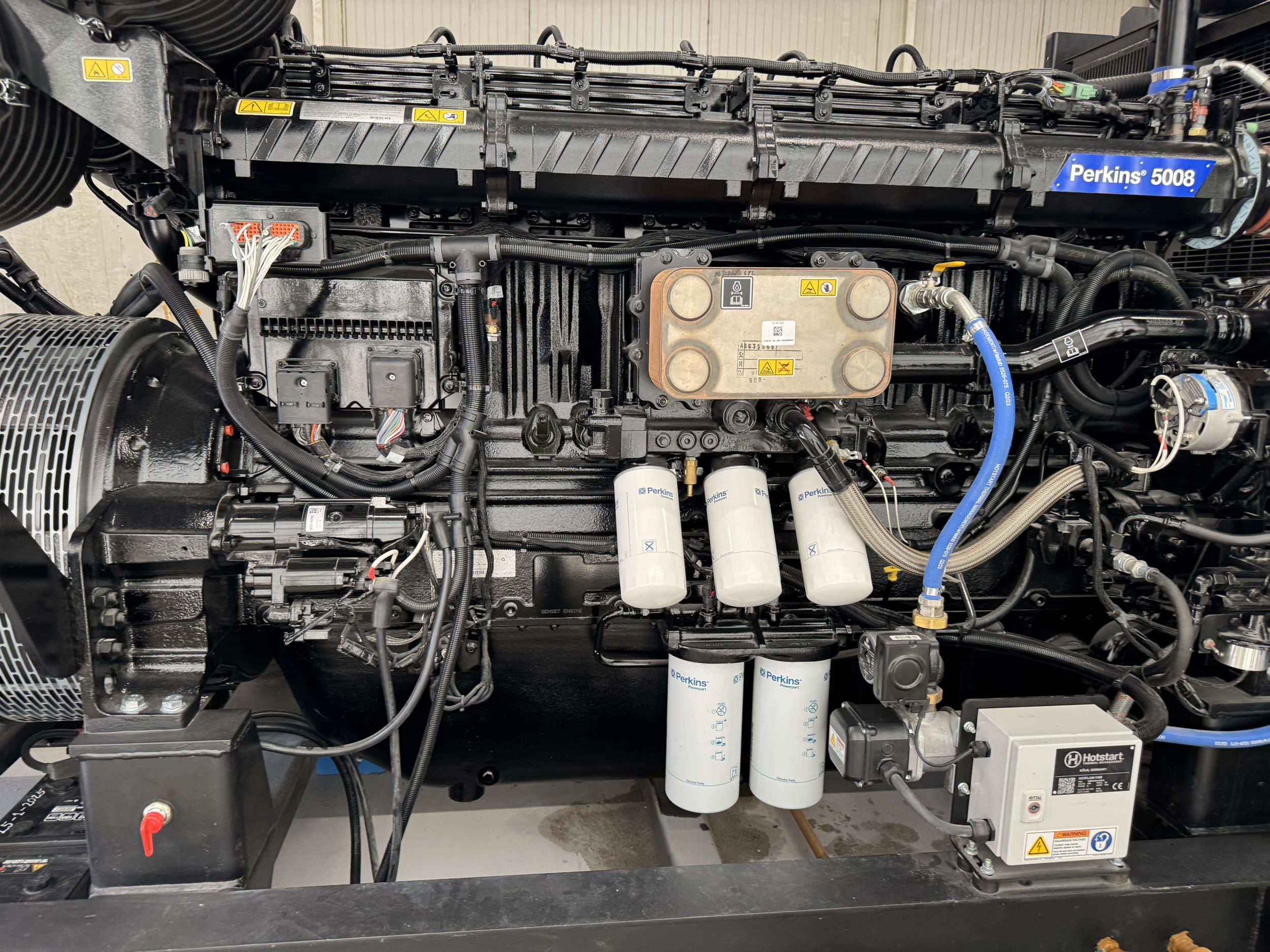

The last thing that operators want is worry about how the pumps they’re overseeing are performing. That means that reliability and efficiency are paramount. With a Perkins-powered Pioneer Pump, you can be sure its packages will deliver. Using its environmentally safe priming system, Pioneer Prime, Pioneer Pump says its vacuum-assisted centrifugal pumps prime much faster than competitors.

“Less time to prime means less time your engine has to be running. That results in less fuel usage while improving the efficiency of the entire operation,” said Will Hatcher, business development manager for Franklin Electric. Even the pumps’ design offers a high return on investment. With features like an oversize shaft and Pioneer’s innovative impeller, pumpage can be transferred more efficiently size-for-size. Those factors help decrease energy usage and improve longevity.

Pioneer and Perkins performance curves

In early 2021, engineering teams from Pioneer Pump and Perkins worked together to introduce unique, color-coded package curves. Traditional pump curves illustrate the performance range of a pump regardless of the engine that’s powering it. The new color-coded curves highlight the ideal operating range for every engine and pump combination.

Purchasers can input head and flow calculations to determine the best engine and pump fit for their desired application. These performance curves make it much simpler for users to decrease the chance of overheating the engine or operating in ranges that the engine may not support. That helps to foster better performance and overall longevity.

Maintenance made easy

Maintaining the most durable and reliable pumps on the market doesn’t have to be a hassle. Preventive service helps to support these pumps and engines, even when they are pushed to the max. Perkins boasts an extensive nationwide distributor network for faster, more efficient service and maintenance.

Services

Discover more about some of the additional services Perkins can offer you.

Services

Discover more about some of the additional services Perkins can offer you.