With more than 70 years’ experience in development and production, Mecalac continues to innovate, boasting a comprehensive portfolio of compact equipment specifically developed to revolutionise operations for construction professionals – saving time, money and labour.

Mecalac is a global leader in the design and manufacture of compact construction equipment. Renowned for stylish design, rental-tough build quality and safety-critical operator technologies, its extensive range is used on sites worldwide.

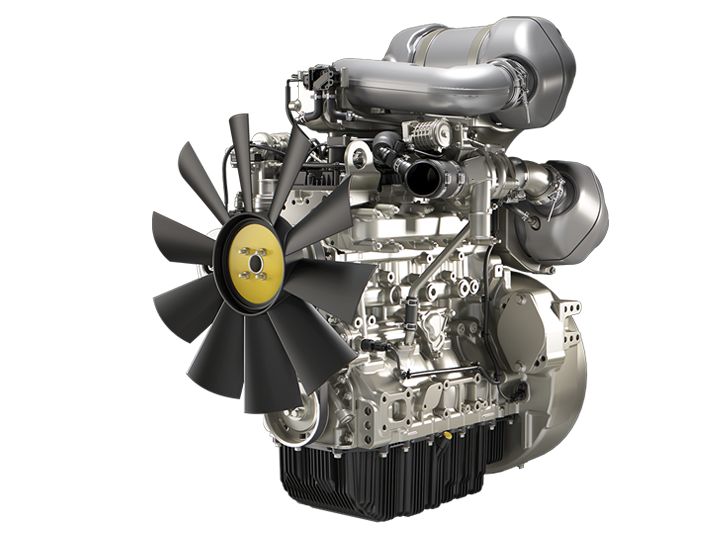

Engine

Read profile

Engine info

Product overview

Gallery

Related case studies

Mecalac is the choice for transport and unload

The challenge

Almost one third of transport accidents on construction sites occur on dumpers. This is mainly due to the front load that obstructs visibility when driving forward, exposing drivers to major accidents. Existing solutions offer limited two-way views or force the operator to physically manoeuvre to get the best view.

The solution

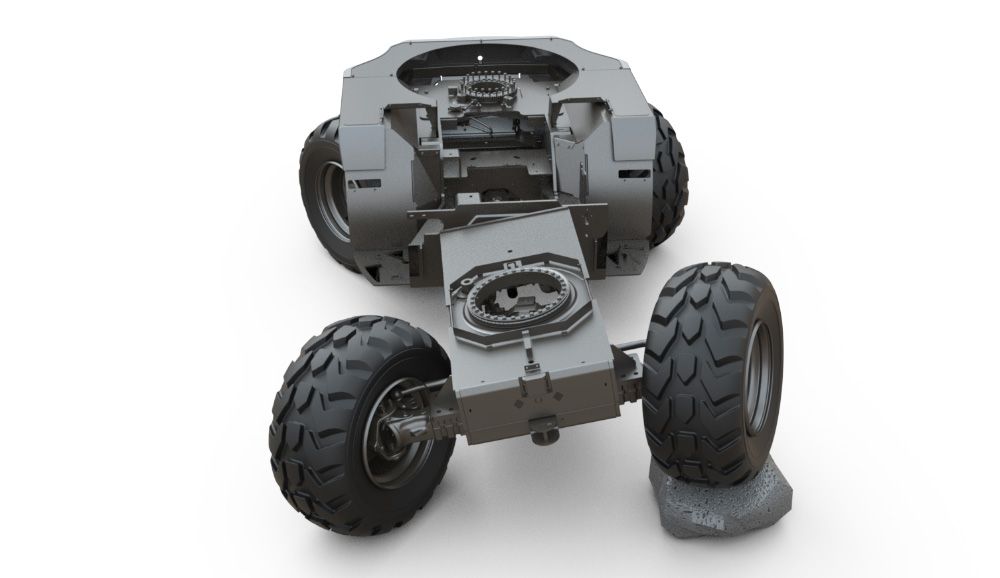

Operators of Mecalac’s new Revotruck can now rotate the entire cab to keep their vision and focus on the job and a view of potential obstacles on the site. The exclusive chassis with central oscillation ensures stability and traction in all conditions. Associated with extreme ease of use and accessibility, the Revotruck makes material transport smarter and safer. The infinite cab positions of the Revotruck open up visibility in all directions, allowing maximum concentration for the drivers on the job and their surrounding elements.

Business impact

With drivers at the heart of the Revotruck design, the revolution of the cab is now possible at the touch of a button. As a result, drivers constantly maintain the correct body posture and help protect themselves against back problems. Additionally, the machine automatically adapts its behaviour to the actual position of the cab (driving direction, speed, steering). This installed intelligence makes the Revoutruck one of the most and safest transport solution available on construction sites. No need to turn a heavy console, just press a button to start a revolution!

Inspired by slope tractors, the Revotruck delivers exceptional stability. The central linkage between the two parts of the chassis offers up to 18° of oscillation, ensuring permanent stability and traction in all conditions. This unique chassis is completed by four equally sized wheels with a switchable steering mode that opens up possibilities for working with superior agility in the tightest spaces. The result is a revolutionary product that combines unlimited visibility from the rotating cab with outstanding stability thanks to its unique chassis. Associated with extreme ease of use and accessibility, the Revotruck takes safety and well-being on the jobsite to a new level.

And it’s powered by Perkins

Manufactured in Peterborough, United Kingdom, the Perkins® 904J-E28TA engine was selected by Mecalac for its compact design and outstanding power density delivering 55 kW and 380 Nm of torque, which are essential engine performance requirements for this application where Mecalac’s customers expect dumpers to be used for a variety of worksite surroundings and conditions.

Mecalac equipment is used on jobsites all over the world. From site managers and rental firms, to owner-operators across numerous sectors, its customers span numerous roles, but all share the common requirements of performance, productivity, reliability and the highest levels of environmental performance. Perkins engines help Mecalac to deliver upon these requirements. For years, Perkins has worked closely with Mecalac’s product managers and engineers on integrating Perkins Stage V engines. This collaboration has ensured that the 904J-E28TA engine meets operational and service requirements.

- Performance is optimised for Mecalac’s dumpers.

- Fuel consumption is optimised to match the operating cycles of the dumper application.

- No additional fluids or additives are required which lowers operating costs and operator training.

- 904J-E28TA’s 500-hour service intervals and single-side service components provide ease of serviceability.

- The 904J-E28TA engine can run on renewable and low carbon intensity fuels including 100% HVO, GTL, BTL and blends of up to 20% biodiesel.

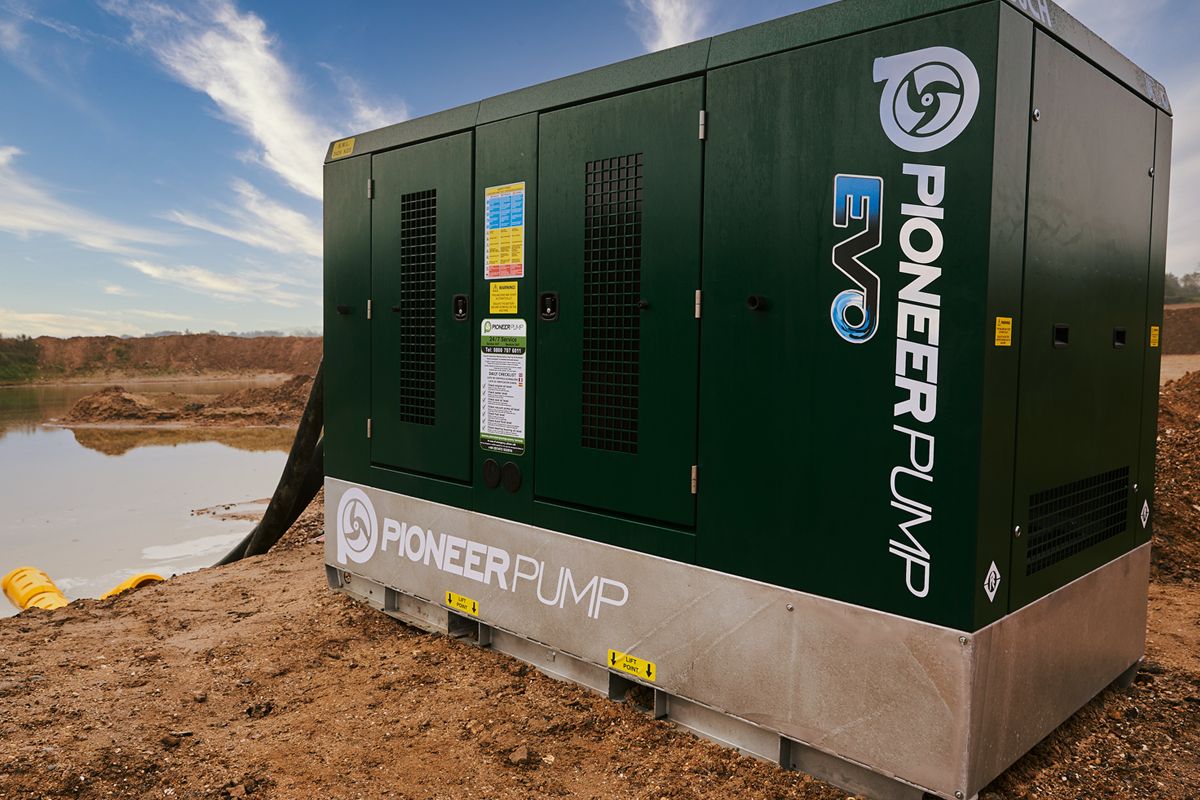

From site dumpers and backhoe loaders, to compaction rollers, wheel loaders and a unique portfolio of excavators, Mecalac delivers superior performance, flexibility and speed.

With a global reputation for engineering excellence, Mecalac’s customers know that a Perkins engine offers the reliability and performance they demand. Mecalac equipment not only delivers excellent power and practicality; it also offers outstanding durability. Indeed, some of Mecalac’s products fitted with Perkins technology are still operational on sites decades after first rolling off the production line.

Services

Discover more about some of the additional services Perkins can offer you.