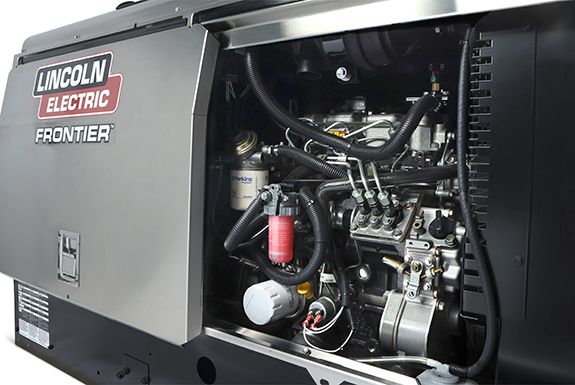

If you’re a general contractor working on structural framework or fabricating pipelines, the multi-process, portable Frontier 400X welder/generator from Lincoln Electric, powered by a Perkins® 403F-15T diesel-driven engine, is ready to perform and take on your every demand. Lincoln Electric has been known for reliable welding equipment since 1895.

Engine

Read profile

Engine info

Product overview

Gallery

Related case studies

Whether you’re a general contractor working on structural framework or you’re out in an oil field fabricating pipelines, having portable, reliable welding equipment is a must. Downed welding equipment not only derails timelines but it may even cause major negative financial consequences.

Contractors can have peace of mind that the multi-process Frontier 400X welder/generator from Lincoln Electric is ready to perform. Powered by a Perkins® 403F-15T diesel-driven engine, the Frontier 400X is designed to take on every demand thrown its way and then some.

Lincoln Electric has been known for high-quality welding equipment since 1895 when brothers John C. and James F. Lincoln founded the company in Cleveland, Ohio. The Frontier 400X is a culmination of more than 125 years of the company’s innovations, which have been leading the industry since the company’s first arc welder hit the field in 1912.

Next-gen technology

The Perkins powered Frontier 400X replaces analog features with modern, digital seven-inch user interface (UI). An industrial-grade system with many features built in, operators can access everything from arc controls to productivity metrics and maintenance reminders on one convenient, simple-to-use screen, even with gloves on.

“The UI gives operators the ability to make the most of the machine. It also gives us flexibility to enhance the user experience and the arc performance itself,” shared Jay Latchic, marketing communications supervisor for Lincoln Electric.

CrossLinc® controls

Lincoln Electric’s patented operator CrossLinc® control technology, accessed with the UI, improves welding quality, productivity and safety across every application. Power and communication is transmitted through a single standard weld cable, enabling greater voltage or current control right at the arc without the need for a control cable.

Fewer cables and wires means a tidier, safer workplace, a quicker setup and full output control at the arc with accurate compensation for voltage drop. This eliminates unnecessary steps back to the power source. Best of all, arc control functions can be finely tuned to suit any welding job with complete ease.

Productivity metrics

Using the UI, operators can review arc and auxiliary power hours. Combined, these factors produce a usage rate based off of the total engine hours. This feature also manages the machine’s Auto-Stop/Start mechanism, which shuts down the engine and the system after sitting idle. Operators can distinguish hours the machine spent for various functions as well as hours that the machine was placed in a standby state along with the associated fuel savings.

Operators also have the ability to set arc memories for key welding modes that are commonly used. These memories can be simply recalled, allowing for smooth transitions between applications and arc improvement.

Maintenance reminders

With uptime such a critical factor, understanding machine health and maintenance needs can’t be understated. The Perkins powered Frontier 400X makes it easy to keep the machine in top condition.

UI maintenance reminders track interval hours for air, oil and gas filters as well as alternator belts and coolant. Oil temperature, fuel level and engine speed can also be reviewed. The system provides notifications when a part is due for maintenance or when levels are outside of typical parameters. Right from the screen, operators can then view the part and associated part number for fast, efficient replacements.

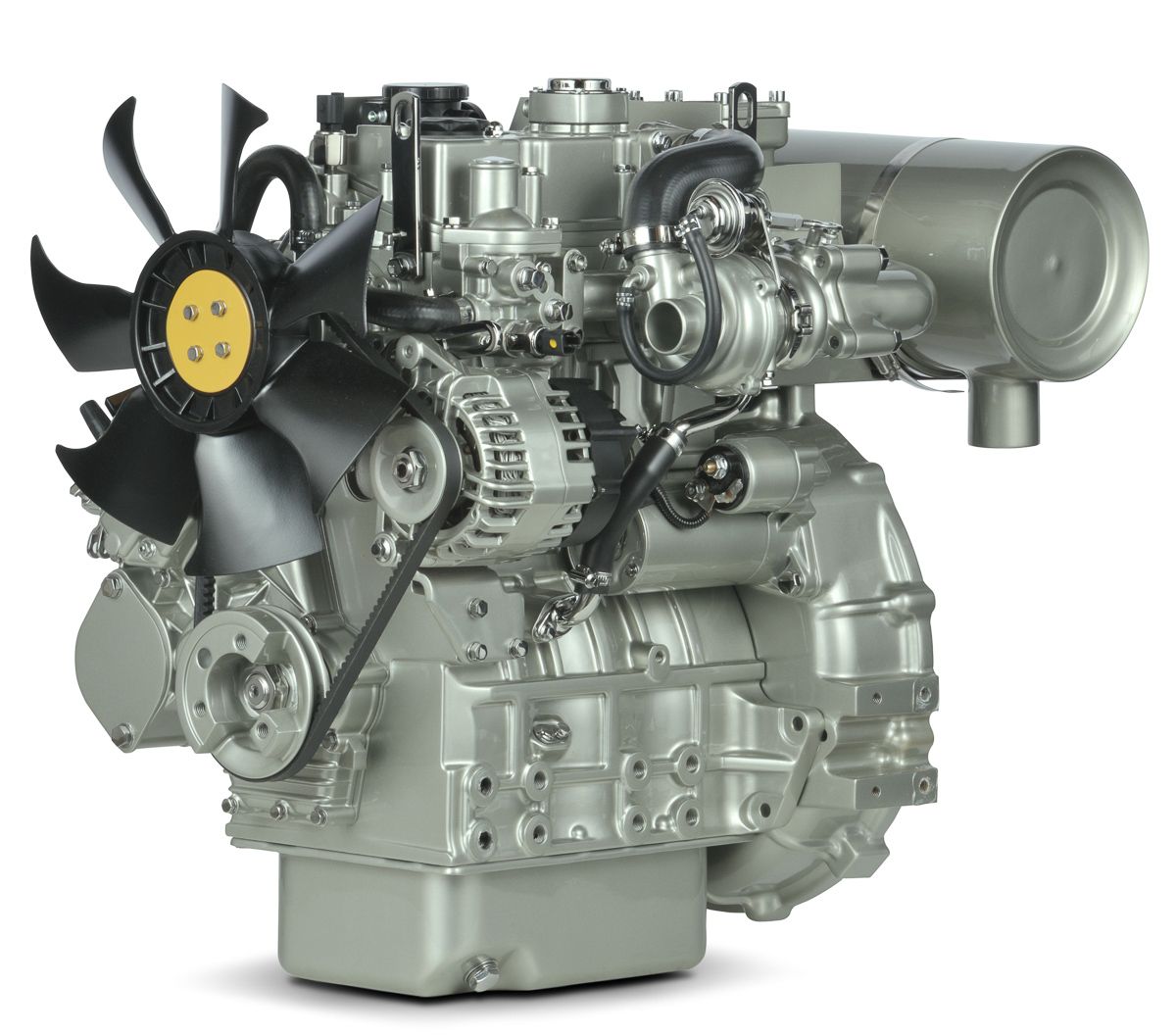

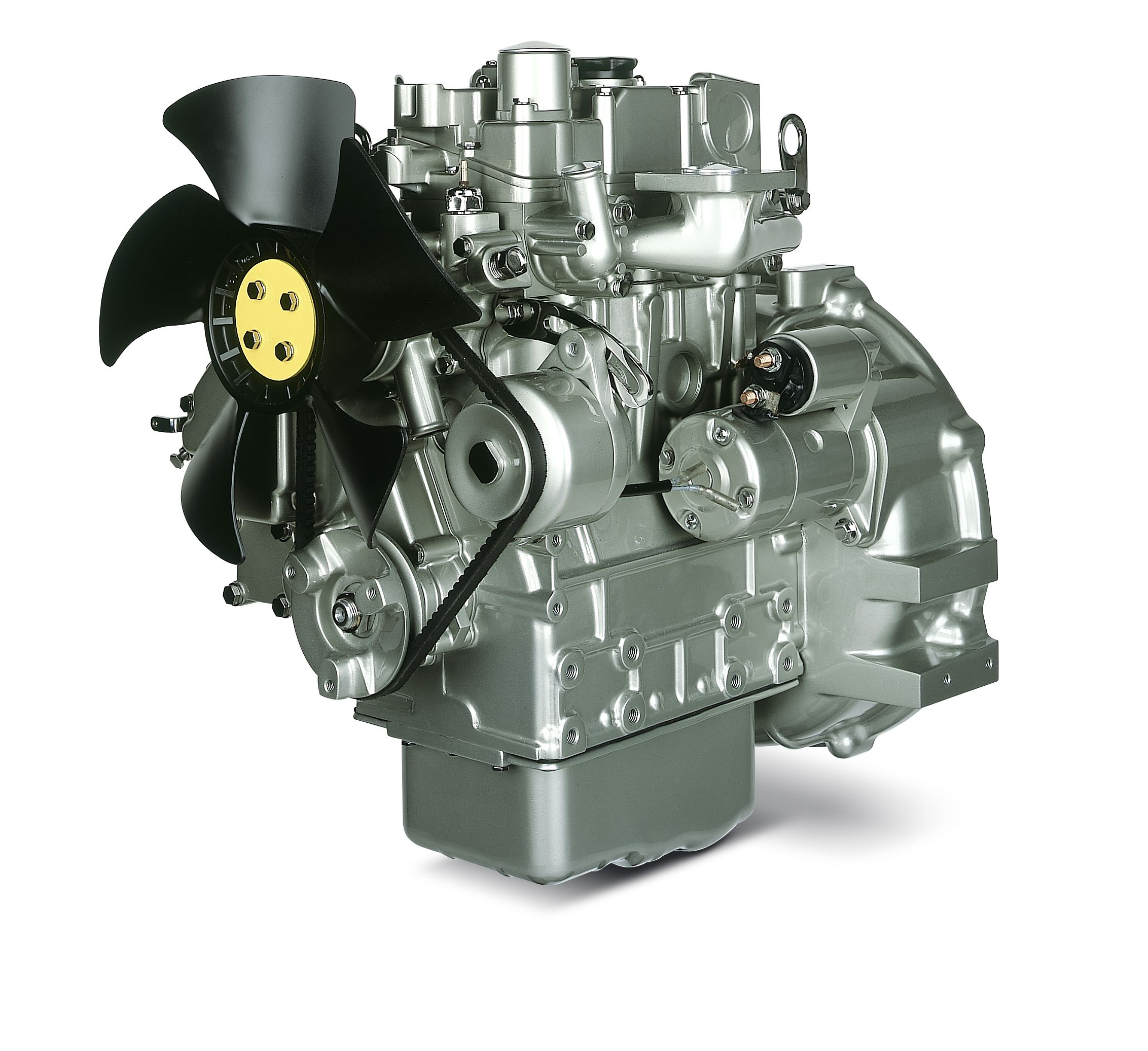

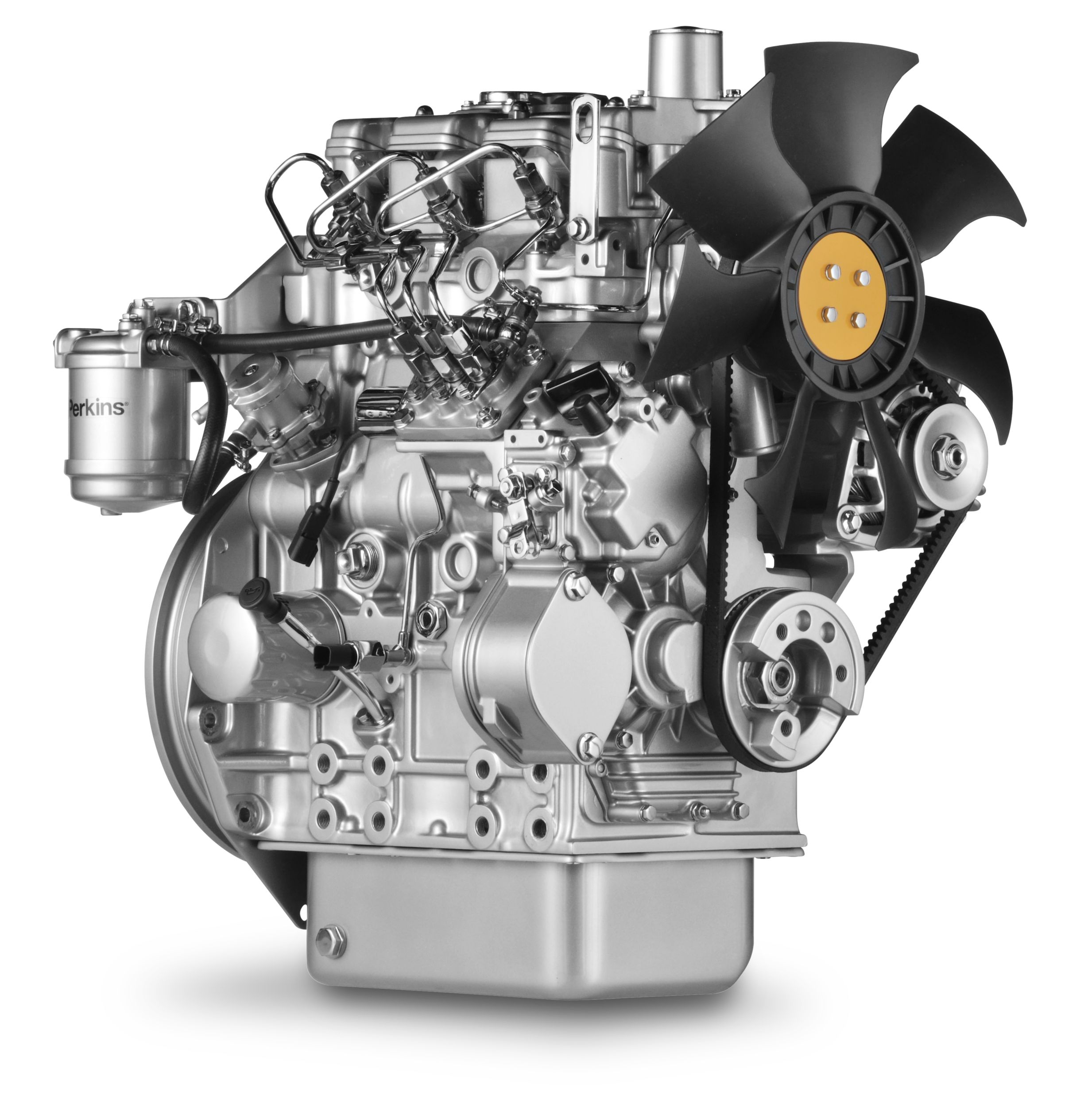

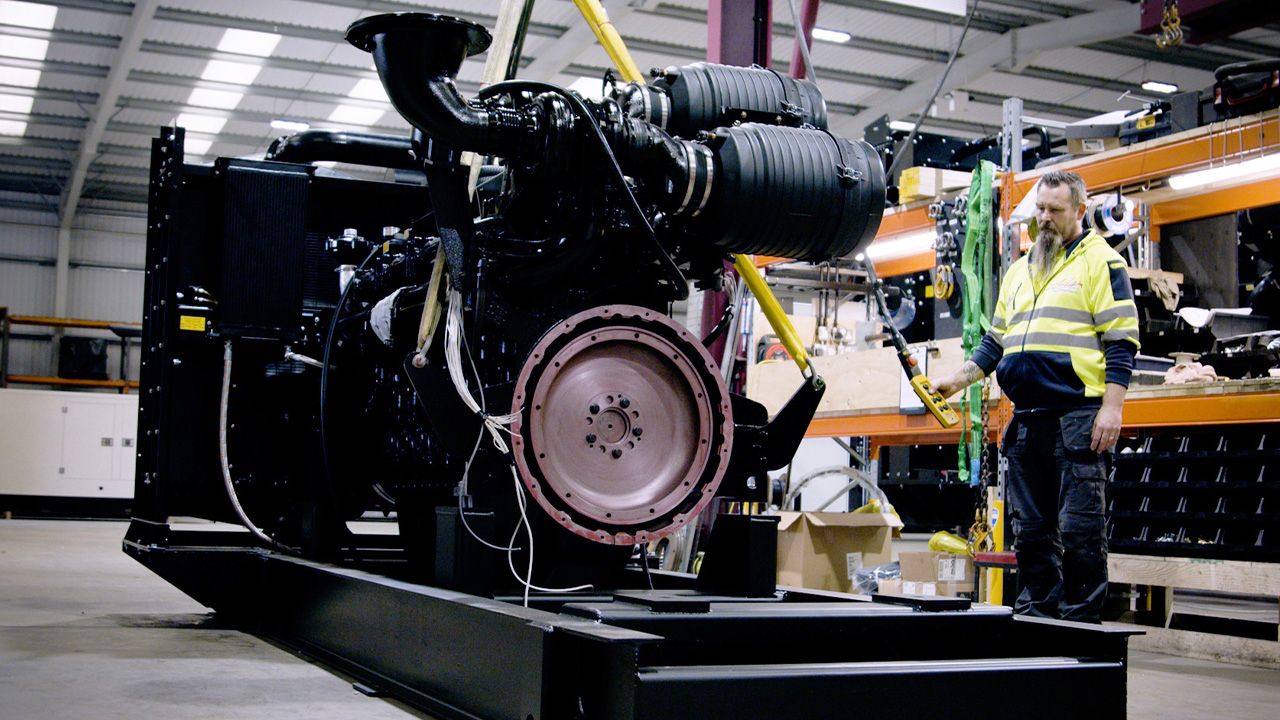

Powered by Perkins

The Frontier 400X welder packs a punch with its Perkins 403F-15T three-cylinder engine turbocharged. This small-but-mighty engine brings 24.7 horsepower while offering a low-noise output. Power dense, the Frontier 400X can achieve a 60 percent duty cycle rating at 400 amps at 26 volts and a 100 percent duty cycle rating at 325 amps at 33 volts. That lends to reliable, steady output for a variety of applications and processes.

“Perkins provides a highly reliable product. We have customers who specifically ask for Perkins products,” explained Nicholas Winarski, product manager of industrial engine drives for Lincoln Electric.

Durability you can depend on

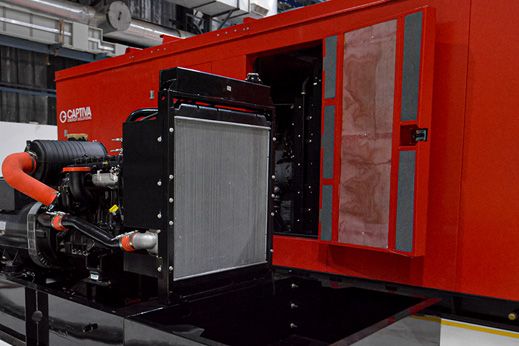

Working out in the field, operators don’t have a choice but to contend with weather conditions. The Frontier 400X has been designed to meet these needs. The machine has been tested for a wide range of conditions, including high and low humidity, rain and snow to meet IEC and CSA certification standards.

Distributors here for you

In addition to the internal parts ordering system, operators can always turn to Perkins for engine maintenance and service. Through its nationwide distributor network, Perkins has technicians readily available to keep Frontier 400X welders and other Perkins powered Lincoln Electric welders in top condition to deliver the premium performance that customers expect.

Services

Discover more about some of the additional services Perkins can offer you.