Established in 1869, Ammann has over 150 years of innovation with dozens of patents under their belt. With a solid foundation established decades ago, customers are able to rely on continuous improvements in technology to help solve daily challenges with their machines.

Engine

Read profile

Engine info

Product overview

Gallery

Related case studies

Ammann is rolling on the jobsite

The Ammann ARX 140 Heavy Articulated Tandem Roller fits well on a wide range of jobsites but is most productive if used in high volume asphalt applications such as highways, industrial areas, or airfields. Its high static ‘dead’ weight is ideally suited as a finishing/ironing static roller or as a compaction tool for sensitive materials. The roller extends the product range from 9 tons up to 16 tons of operating weight. The machine design, drum construction, operator workplace and engine compartment are among the key features.

Immediately apparent on the ARX 140 is the absence of front and rear crossbeams along with a new symmetrical cab that improves safety and productivity. Well-designed and positioned fuel and water tanks add to the impressive appearance and improve access to components. The design changes make the machines more compact while improving sight lines to all drum surfaces and edges. The 360° visibility from the operator station establishes a new industry standard, providing operators with an exceptional view of the entirety of the machine, improving productivity and safety. The spacious cab is also extremely quiet. It is suspended and isolated from external heat and vibration from the operator station, keeping operators comfortable, fresh and focused.

The advanced operator station has integrated, centralised controls that are located near the operator and easy to reach at all times, regardless of the seat position, which reduces reaction times and improves safety. The machine is equipped with fingertip steering (FTS), making it more operator-friendly, comfortable and easy to control. The FTS replaces the traditional steering wheel and allows operators to keep both hands on the armrests for improved comfort. The FTS also offers advanced palm support that prevents fatigue and injuries from repetitive motions. A new 10-inch control display helps operators control all machine functions simply, safely and quickly. Additionally, it provides an overview of fluid levels, indicators and machine status and warnings. The display is installed on an adjustable support, located in front of the operator, and moves with the seat for easy viewing.

Serviceability, reduced downtime and total cost of ownership are essential to profitability. Machine data is collected from all regions and is now reflected in innovative machine development as well as the ECOdrop philosophy. ECOdrop is a technical solution that makes the machines mostly maintenance free. Maintenance is faster and more convenient thanks to a highly accessible engine compartment with a robust design that protects all major components. All maintenance and service points are accessible from the ground. Machines are equipped with external draining points for all operational fluids such as engine oil, hydraulic oil and coolant. All rollers are equipped with an auto-diagnostics system that communicates with service technicians. External testing ports on hydraulic components enable quick diagnosis and reduce machine downtime.

And it's powered by Perkins

Perkins is a well-known brand worldwide providing the most comprehensive range of reliable power solutions. Ammann has chosen Perkins for their latest generation of heavy tandem rollers to ensure global field support and serviceability to their customer base in regions such as Australia, New Zealand, North America, North Africa, and South Korea where Perkins’ local outlets can support their customer’s requirements and needs. A commitment to collaboration from Perkins and Ammann defines the mutual approach to doing business and adding value to Ammann’s customers.

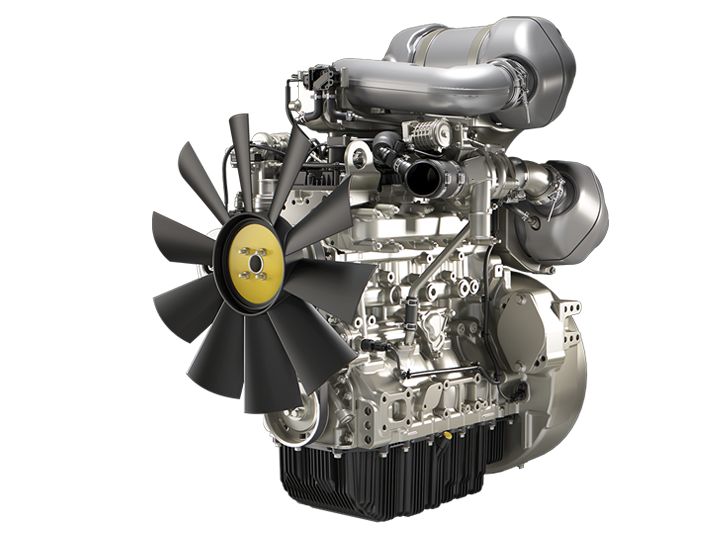

Perkins® 904 Series EU Stage IIIA and V or equivalent are well-established in the global market and are selected by Ammann to meet those emissions requirements and for the offering of high quality and reliable engine options. The 904 Series is a compact powerhouse that has undergone thousands of hours of real-life testing assuring Ammann they will have a high-quality engine at the heart of their machines with a reliable performance.

“With the new generation of heavy tandem rollers, Ammann has decided to connect its name with one of the world’s strongest engine manufacturers, Perkins. Its latest EU Stage V/U.S. EPA Tier 4 Final engines are well established in the market, known for their quality and reliability. Another important fact is global aftersales support of Perkins engines, which is one of the key values that Ammann is bringing to its clients through the complete product line.”

Vlasta Medek, head commercial manager

Services

Discover more about some of the additional services Perkins can offer you.