The process of fusing pipe by machine, which involves joining two pieces of thermoplastic pipe with heat and pressure, was pioneered by McElroy Manufacturing in 1969. The company created the world’s first centreline-guided, semi-automatic, hydraulic machine for fusing 2” to 6” pipe. Today, McElroy’s lineup of fusion machines includes more than 20 manual, rolling hydraulic, tracked hydraulic and specialty models.

Engine

Read profile

Engine info

Product overview

Gallery

Related case studies

The future of fusion is here

Wherever there’s water, oil, natural gas or other liquids to move, you’ll find fused pipe. It’s seamless, leak-free and resistant to corrosion, vibration and pressure surges — all of which means it lasts longer (up to 100 years) and requires less maintenance than traditional piping systems, bringing down costs.

The process of fusing pipe by machine, which involves joining two pieces of thermoplastic pipe with heat and pressure, was pioneered by McElroy Manufacturing in 1969. The company created the world’s first centreline-guided, semi-automatic, hydraulic machine for fusing 2” to 6” pipe. Today, McElroy’s lineup of fusion machines includes more than 20 manual, rolling hydraulic, tracked hydraulic and specialty models.

For operations fusing long pipelines and working on tough terrain, the pipe fusion machine of choice is McElroy’s TracStar®. Self-propelled via rugged, dual rubber tracks, it can traverse mud, snow, loose soil and grades of up to 30 percent with ease. The chassis-mounted carriage allows for easy pipe loading and movement along the pipe, and it’s removable for access to tight spaces. And because every TracStar can drive itself up and down the ramps of a trailer, there’s no need to bring a crane on site.

Making every operator a star

In 2021, McElroy launched the next generation of TracStar machines. New iSeries models feature the FusionGuide Control System, integrated software that guides the operator through every step of the process. After the operator prepares the pipe and enters all joint details, the system manages machine pressures, heater actions, shift sequences and more to ensure every fusion meets standards.

“Our customers continue to face labour challenges in terms of finding qualified operators,” says Geoff Koch, McElroy’s vice president for product development. “Our goal is to make it easy for anyone to run these machines and deliver a repetitive, reliable fusion joint every time.”

One way McElroy aims to achieve that goal is by providing options for different operator experience levels and jobsite requirements. iSeries models are the only pipe fusion machines available with three levels of control in a single machine: manual, semi-automatic and fully automatic modes.

Compliant, convenient, quiet

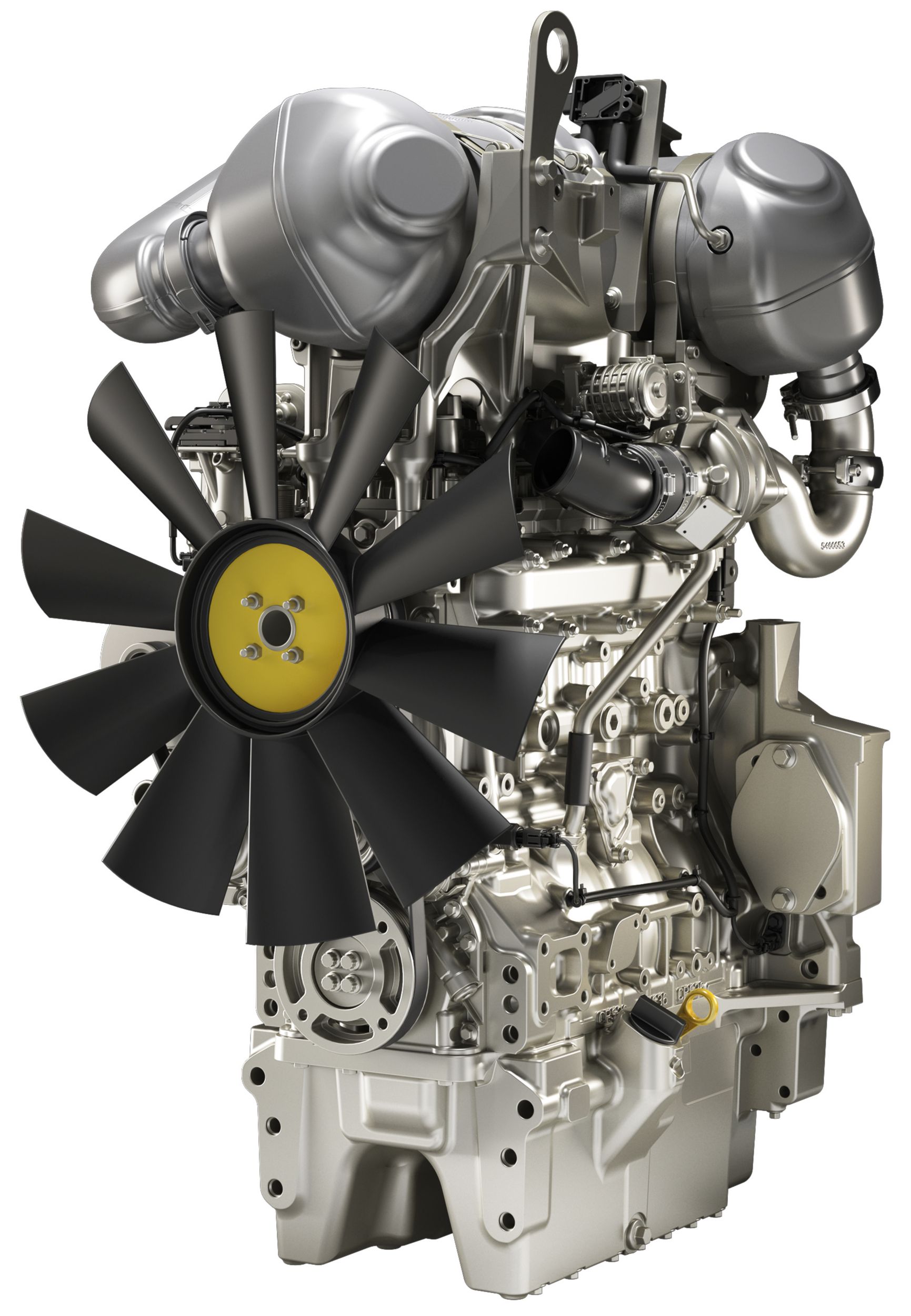

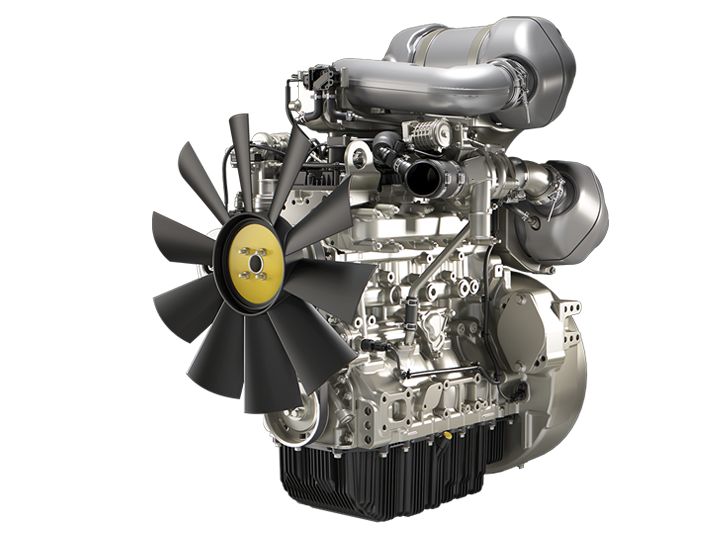

Another update on iSeries machines is a move to the latest emissions-compliant engines. All three models — 630i, 900i and 1200i — are powered by Perkins® 904J-E36TA U.S. EPA Tier 4 Final/ EU Stage V engines. “Stage V is a requirement for Europe, but we also chose Perkins because the Stage IIIA previous model is so similar,” Geoff says. “With equipment running worldwide, we need a dual-certified platform to sell into certain countries. The commonality between the models reduces the amount of design differences on our end.”

McElroy also is taking advantage of the engine’s Power Take-Off (PTO) to drive some hydraulics on iSeries machines. “One thing that makes the TracStar unique is that our primary engine load powers an onboard electric generator, which adds convenience since the customer doesn’t have to transport a generator on site,” Geoff says. “The PTO on the Perkins engine provides the opportunity for a very streamlined package.”

In a series of product showcases held before the first iSeries models were shipped, another feature of the Perkins engine stood out — a lack of noise. “People commented on how quiet it was, even running at full throttle,” Geoff says. “That’s becoming more important for anyone working in urban areas.”

Support in the pipeline

iSeries machines are the first McElroy products with Perkins engines, but Geoff has great confidence in the brand’s reputation for service and support. “If there’s an engine issue, we know our customers can access the Perkins service network locally wherever they are. And as equipment ages, they’ll have access to the parts they need to keep it running,” he says. “The Perkins name carries that commitment of support.”

“People commented on how quiet it was, even running at full throttle. That’s becoming more important for anyone working in urban areas.”

Geoff Koch, McElroy’s vice president for product development

Services

Discover more about some of the additional services Perkins can offer you.