Atlas Copco has approximately 40,000 employees and with customers in over 180 countries, it's a large global company that acts locally to serve its customers and keep projects going. Recognised as being one of the pioneers in technology and engineering with innovative products and solutions, Atlas Copco is proud to serve the US and Canadian markets with its global network and technologies.

Engine

Read profile

Engine info

Product overview

Gallery

Related case studies

Atlas Copco's XAS 950 Perkins-powered air compressor gets all the jobs done

Swimming pools. Communication cables. Refurbished metal ships. What do they all have in common? There’s a good chance they were all made ready to use courtesy of a whole lot of pneumatically-compressed air. Atlas Copco’s new XAS 950 air compressor provides high-compressed air flows for applications like gunite, horizontal directional drilling and old-school sandblasting. Specifically, the compressor shoots out up to a whopping 950 cubic feet of air per minute (with up to 200 PSI), making it as powerful as it is versatile.

“In the past, we had one compressor model that just tackled one application, and then we had another model right behind it that could do the next application. But the technology on the engine side pushed us to stay current and allowed us the opportunity to marry those applications together,” explained product marketing manager Clayton Jones.

“So from a control system standpoint, we have one of the most technologically versatile controllers. The technology is going away from old pneumatic regulation system, and it's now done through the user-friendly controller, with variable pressure and flow. To conquer all those applications, you need to have these technologies and versatilities built within.”

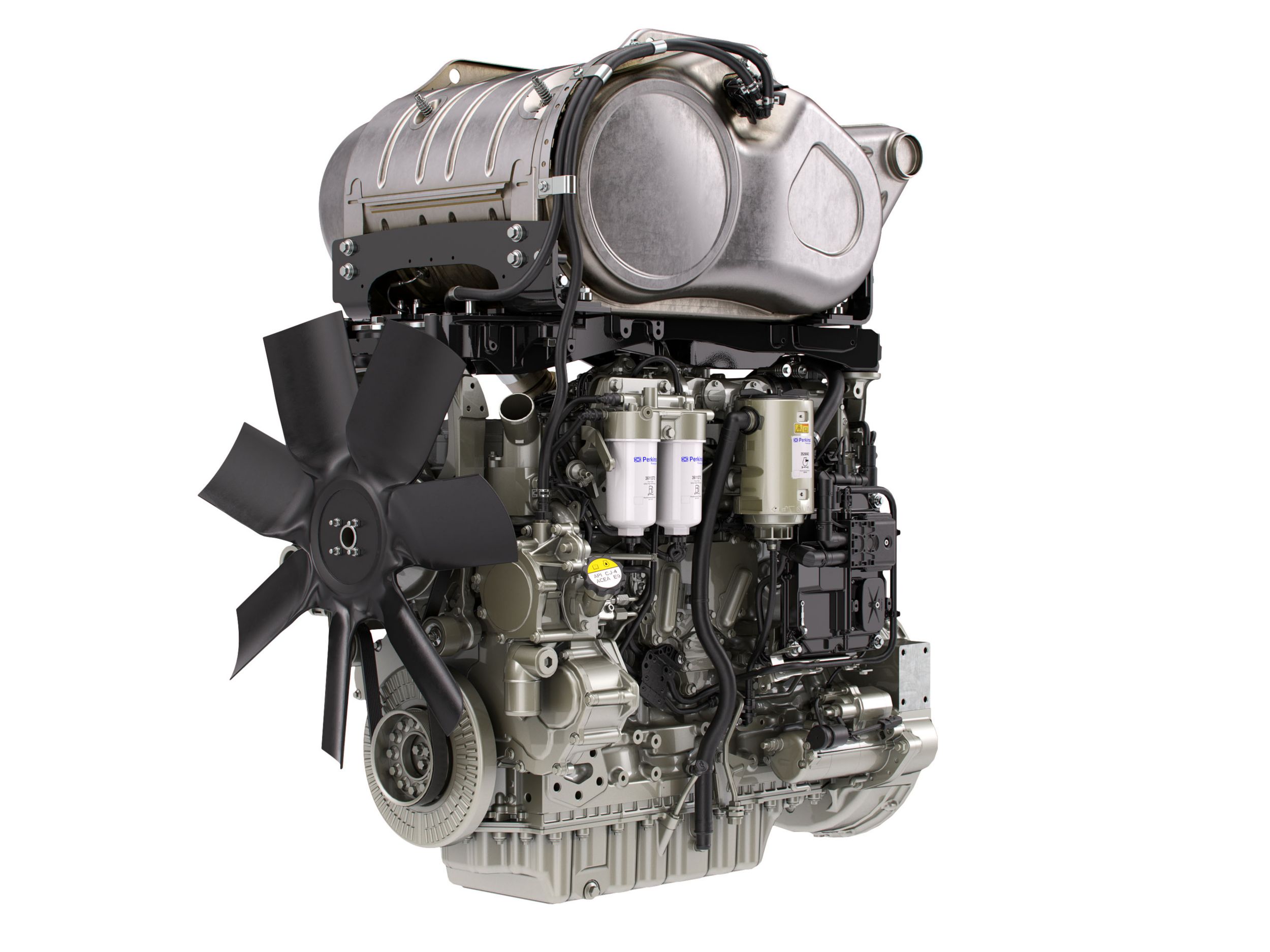

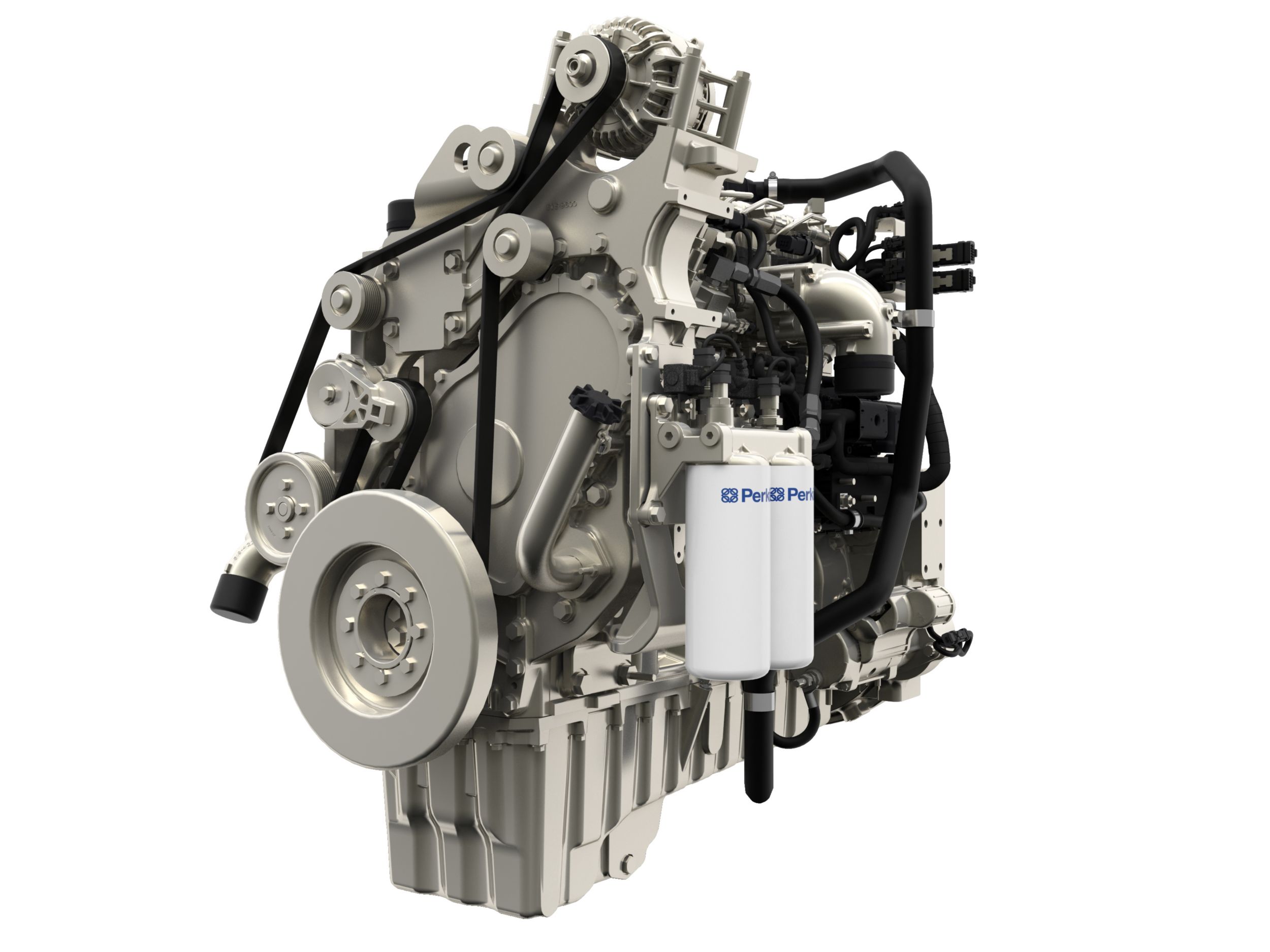

Power trip

Powered by a Perkins® 1206F-E70TTA engine, the XAS 950 is a single-axle, oil-injected mobile compressor offering up high flow in a small package to maximise onsite usage while minimising transportation costs. With the engine reaching up to 302 horsepower, the compressor truly can tackle any job put in front of it. Technological capabilities aside, the Atlas Copco engineers knew the Perkins® 1206F U.S. EPA Tier 4 Final engine was their winner when they realised they could hit the compact footprint they were going for. “The technology of the engine pushed us to stay current with our technology,” said Claytpn. “It allowed us the opportunity to marry those together.”

The 6-cylinder, 7-litre engine’s top-mount configuration would enable Atlas Copco to include their wrap-around canopy, a popular compressor feature that keeps the noise level down so it can be run in residential or densely populated areas with minimal complaints from fed-up nearby residents. After all, why completely redesign something when you can instead simply make it a tad taller—while simultaneously amping up the power? Turns out, the marketplace agrees.

“Using the Perkins® 1206 engine has really opened up a completely new market for us. We could essentially hopefully sell about double what we had forecasted,” Clayton revealed. “We haven't even hit the two-year mark and we've already done some pretty good damage from a production standpoint.”

Make it easy

The XAS 950 was designed with usability at the forefront. Its small size allows for enhanced mobility, which comes in especially handy in tight spots. And no added costs of logistics companies since the machine can simply be pulled behind a truck. Users can even save money on fuel, because the highly versatile controller being powered by the Perkins 1206 engine at the heart of the machine allows the compressor to run lower loads as needed.

“A lot of times in drilling, it's not going to be 24 hours a day that they need this full load. And so our machines will automatically recognise this and cut down on fuel consumption,” Clayton said. “You start adding those figures up over a year's time, and it can be pretty substantial savings.”

Even the air compressor’s serviceability is all about the user-friendliness (much like the Perkins engine inside). Fluids are plumbed to the outside of the containment for simple draining. Gull wing doors make for easy (not to mention safe) access to engine and electrical components, the air end and just about any filter you can imagine. Basically, no crawling needed here. “If we can cut a two-hour service job down to one hour, that's a saving. So it’s a trickle effect,” explained Clayton.

“The technology of the engine pushed us to stay current with our technology. It allowed us the opportunity to marry those together.”

Clayton Jones, product marketing manager

Services

Discover more about some of the additional services Perkins can offer you.