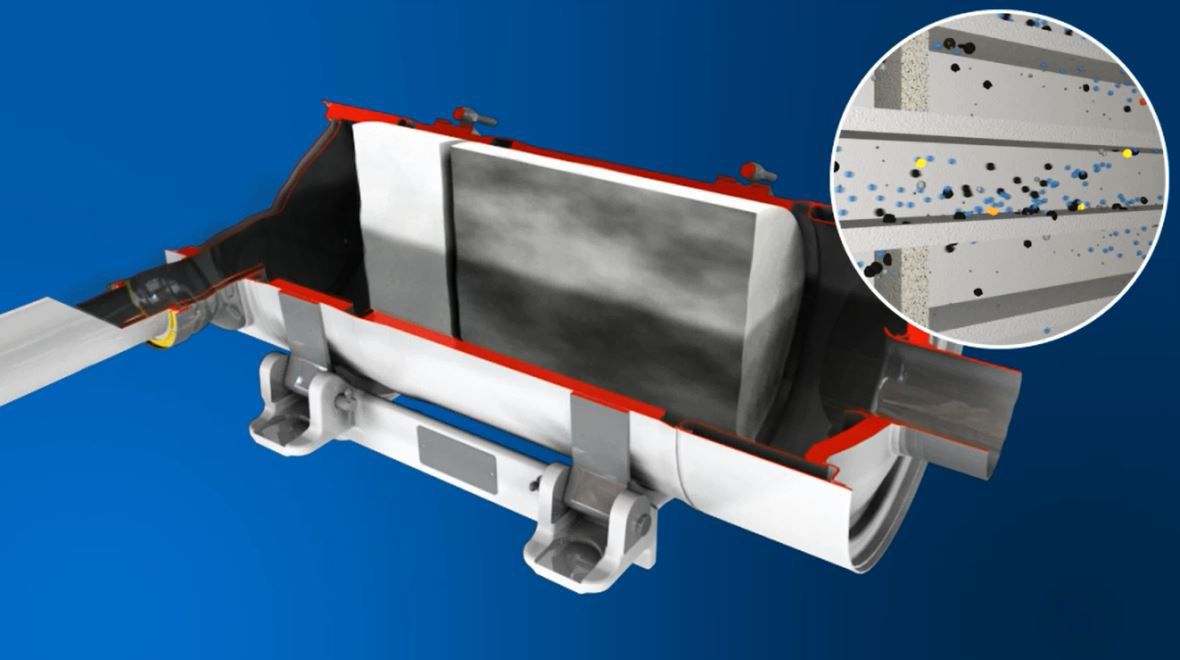

In contrast to higher temperature active regeneration, passive regeneration – sometimes referred to as ‘passive regen’ – uses normal exhaust temperatures and nitrogen dioxide (NO2) as the catalyst to oxidise PM in the DPF.

EU Stage IV/U.S. EPA Tier 4 Final emission standards have reduced the amount of PM or soot entering the atmosphere by up to 98 percent when compared with emissions from non-regulated engines. Ultra-fine particulates pass through and are captured by the DPF. This achieves the required reduction without compromising machine reliability and productivity. Over time, these particulates build up. To maintain the performance of the DPF, passive regeneration is used to oxidise the PM within the filter. It’s a continuous process that allows the DPF to perform as intended without the need to raise the temperature.

Passive regeneration occurs, to some extent, in all DPF systems. Perkins has engines are available that are passive only – so there’s no need for any active system.

If you’re looking for a simple solution that is invisible to the operator, passive regeneration is a logical choice. There are no extra lights or controls to increase the operator’s workload. It’s a continuous process, allowing the DPF to perform as intended. And with Perkins offering service-free systems, operators won’t have to worry during the life of the machine.

A DPF system utilizing passive regeneration delivers reliable operation over a wide variety of applications and duty cycles. Out in the field or on site, that means excellent fuel consumption,no disruption to the operator, no downtime and, therefore, increased productivity for the operator.

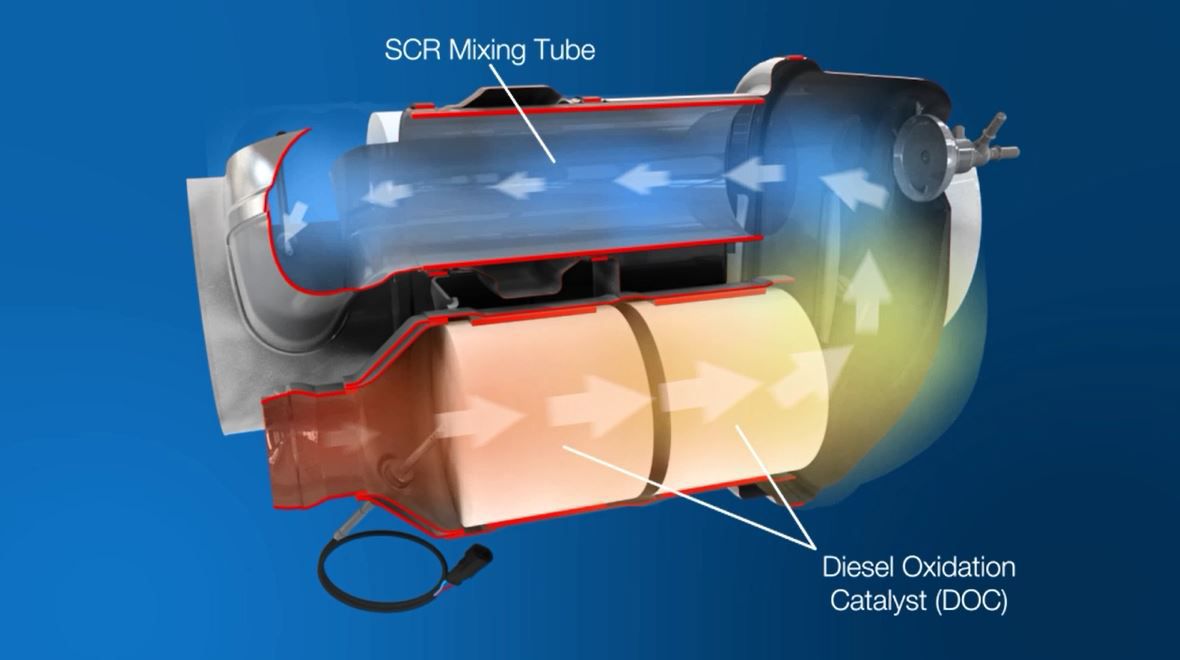

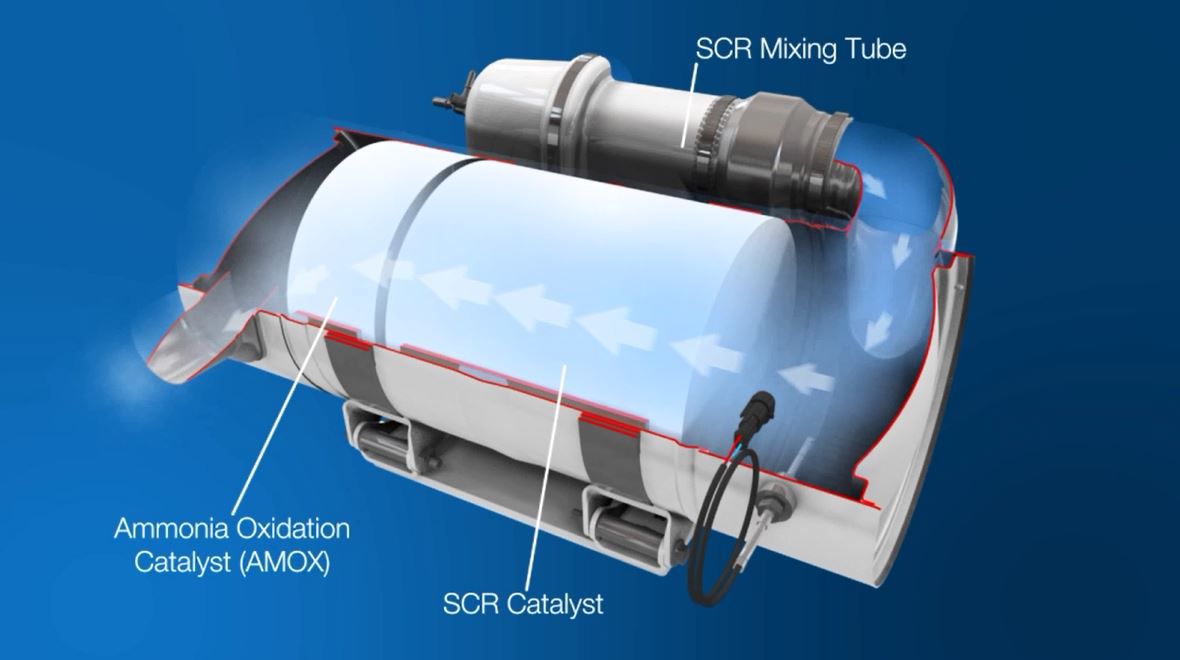

If you’re using a selective catalytic reduction (SCR) system you need diesel exhaust fluid (DEF) for the system to work.

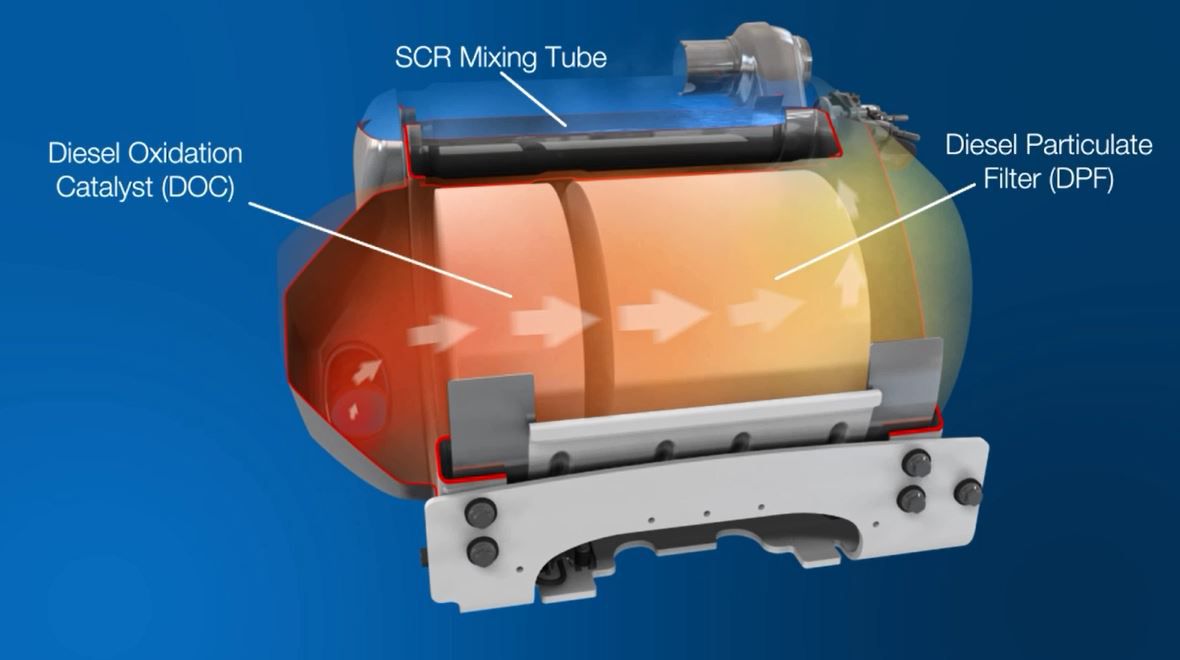

Learn MoreA diesel oxidation catalyst (DOC) is an aftertreatment component that is designed to convert carbon monoxide into carbon dioxide and water.

Learn MoreOur diesel particulate filter (DPF) solutions capture a high percentage of particulate matter or soot.

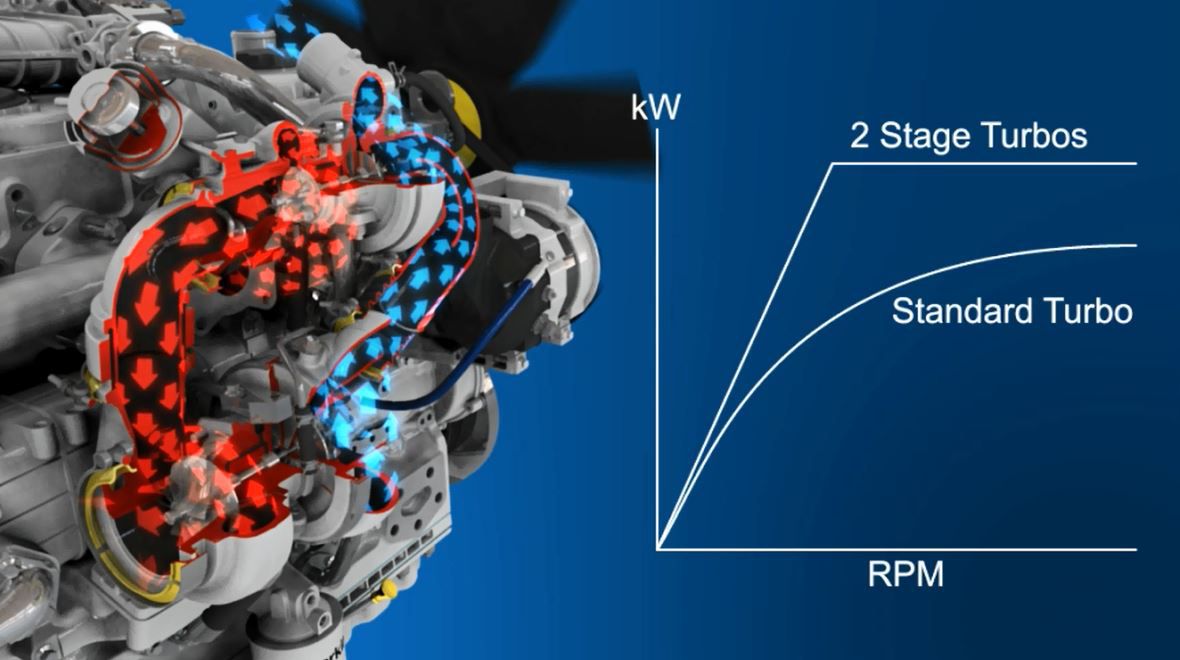

Learn MoreA series turbo set-up involves two turbochargers installed to operate in sequence.

Learn MorePassive regeneration is an approach used to oxidise particulate matter (PM) in the diesel particulate filter (DPF).

Learn MoreOne of the options available for reducing NOx emissions is selective catalytic reduction (SCR), used on a number of our engines.

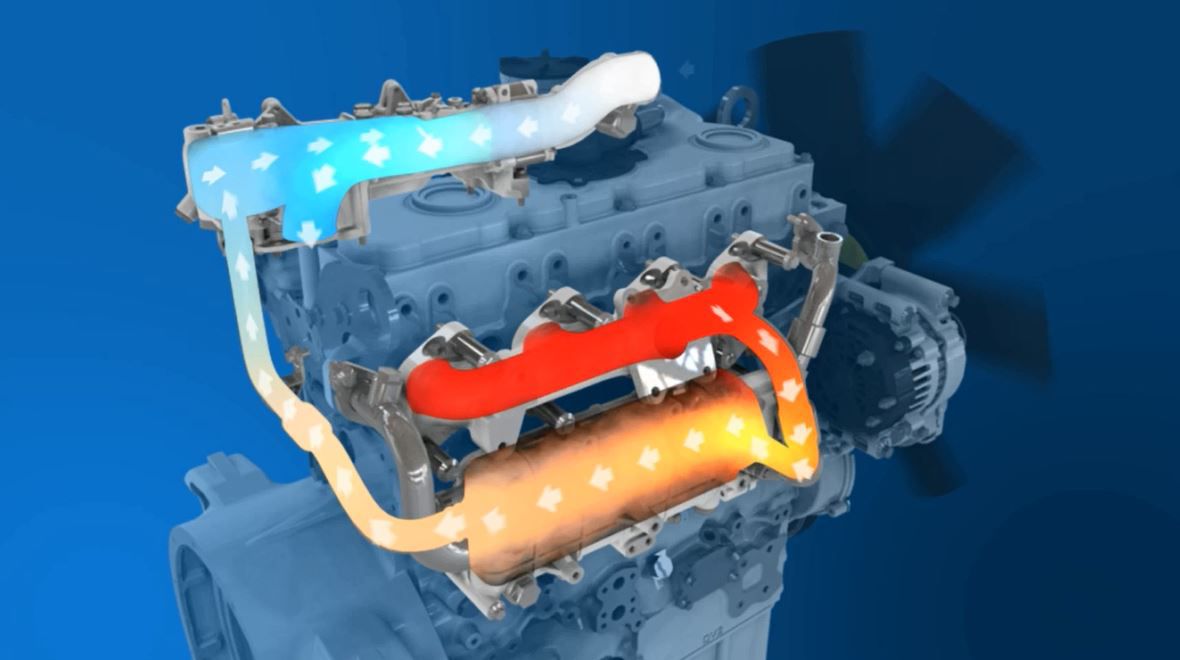

Learn MoreOne of the technologies available for the reduction of oxides of nitrogen (NOx) is exhaust gas recirculation (EGR).

Learn MoreReducing particulates and optimising fuel consumption are primary reasons for adding high pressure common rail to our engines.

Learn MoreIf you're ready to receive trusted advice from a Perkins expert, speak to our team today.

Connect with usOur digital magazine with the latest news, interviews and analysis.

Read moreYour regional Perkins Distributor can provide local, on-the-ground engine support.

Learn More