The introduction of a new range of EU Stage V engines has coincided with Perkins achieving 1.3 billion hours with diesel particulate filters (DPFs).

“We’ve been able to deliver outstanding value to our customers, with our team taking a huge amount of pride and care when it comes to developing durable and reliable aftertreatment systems,” said Ajay Prasher, product marketing. “Knowing that our emissions technology has helped the industry to build hospitals, universities and infrastructure projects is very satisfying.”

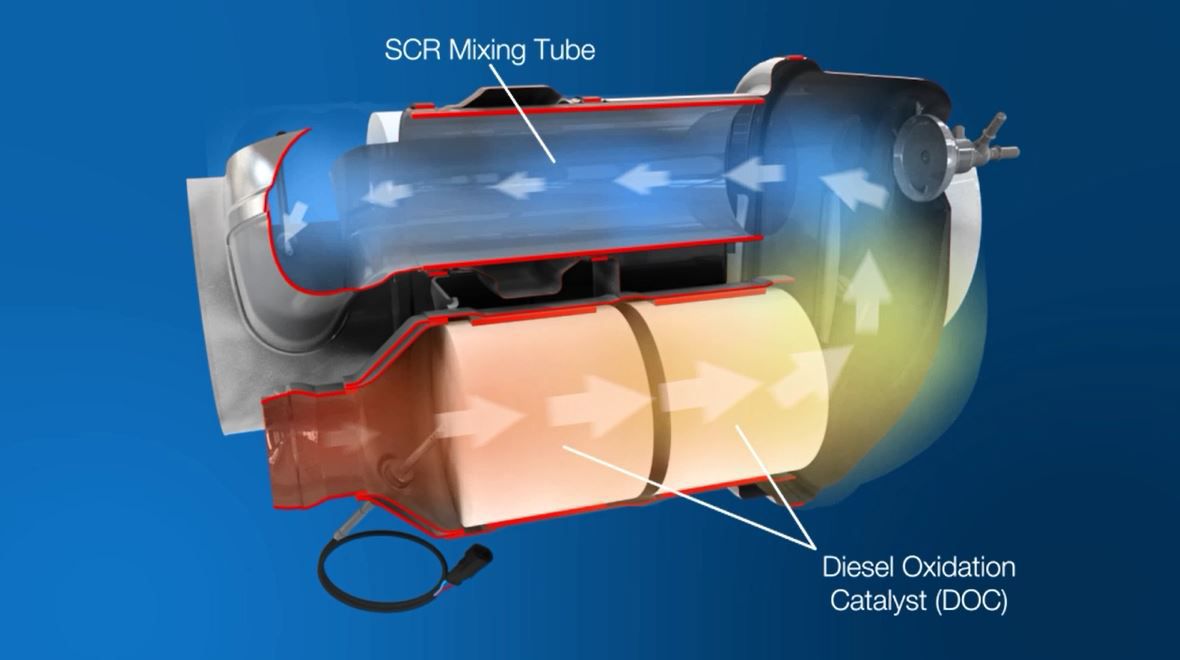

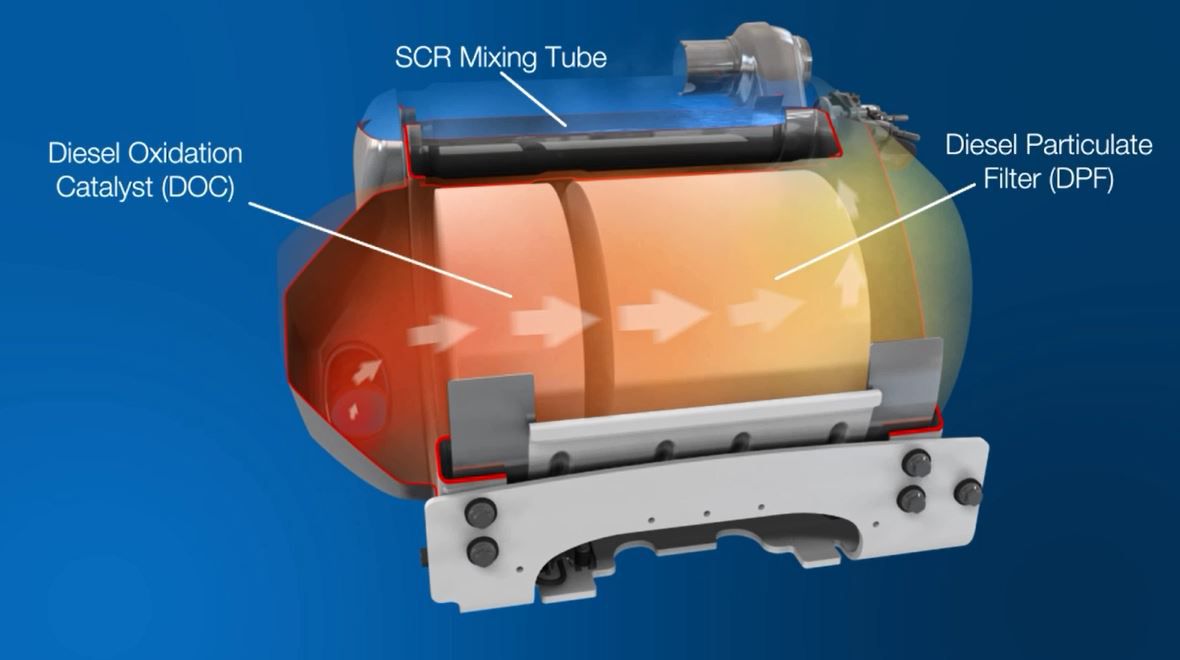

Perkins has been developing aftertreatment systems since 2007 and over that time, aftertreatment has changed significantly. New aftertreatment structures have allowed us to shrink the aftertreatment while meeting the stringent emissions limits.

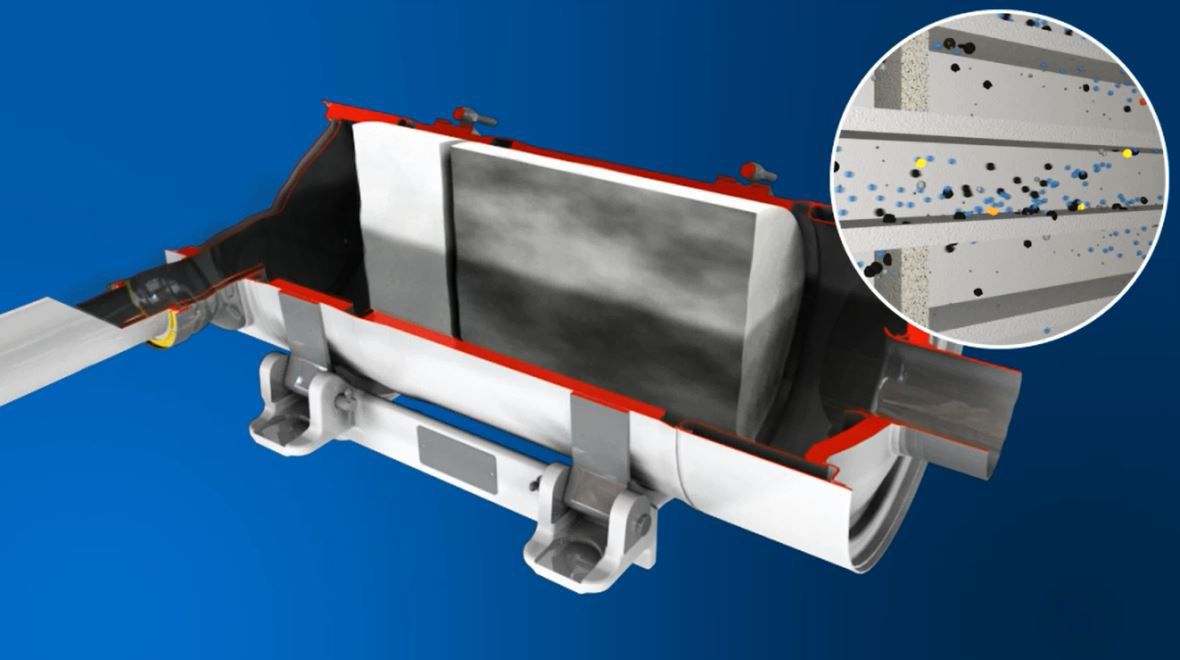

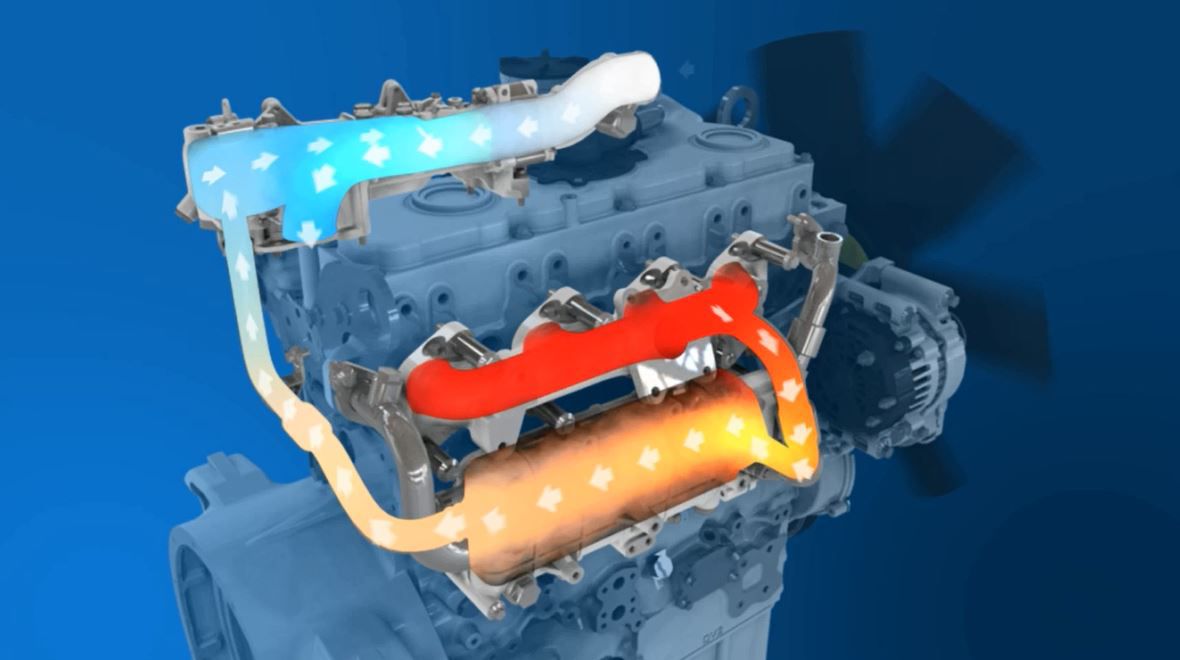

“High exhaust temperatures are critical to regenerating the DPF and removing soot. Our first aftertreatment designs required extremely high engine temperatures, for example more than 700°C. With our latest catalyst technology, we’ve been able to lower these to 300°C meaning we can regenerate the DPF more of the time, with passive regeneration meaning more seamless operation,” said Ajay.

Perkins customers need engines and aftertreatment which won’t let them down – whether it’s in the Arctic circle where temperatures are below 25°C or the Colorado mountains where air pressure is extremely low – so we’ve tested our systems over and over again to make sure they’re robust.

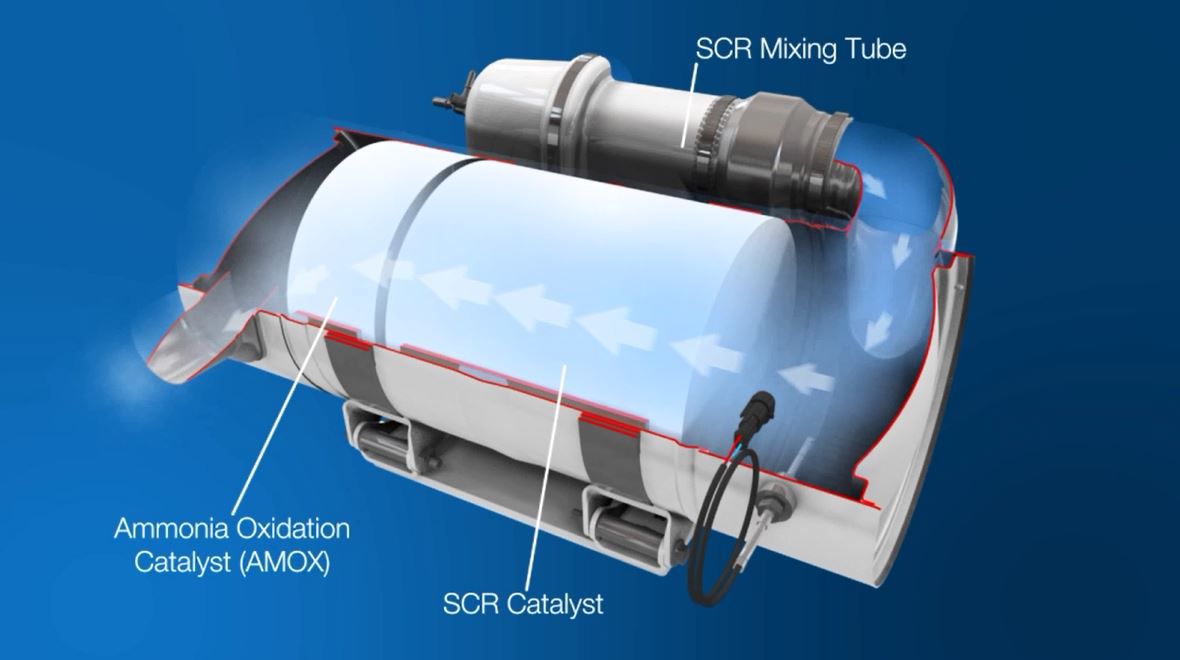

If you’re using a selective catalytic reduction (SCR) system you need diesel exhaust fluid (DEF) for the system to work.

Learn MoreA diesel oxidation catalyst (DOC) is an aftertreatment component that is designed to convert carbon monoxide into carbon dioxide and water.

Learn MoreOur diesel particulate filter (DPF) solutions capture a high percentage of particulate matter or soot.

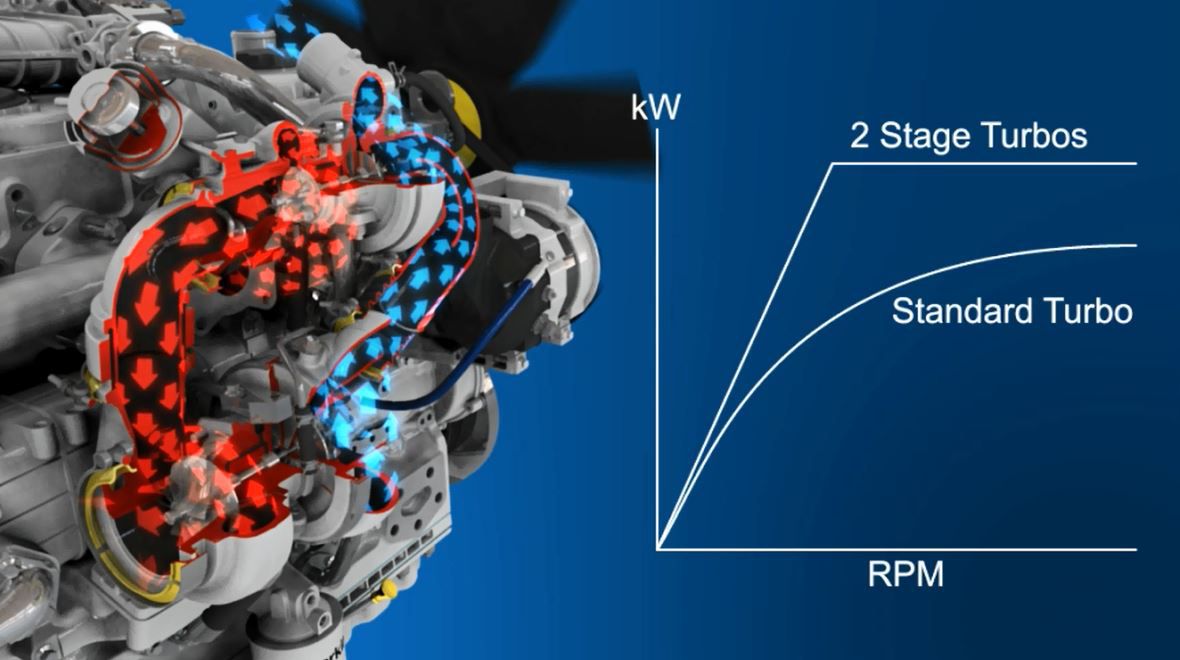

Learn MoreA series turbo set-up involves two turbochargers installed to operate in sequence.

Learn MorePassive regeneration is an approach used to oxidise particulate matter (PM) in the diesel particulate filter (DPF).

Learn MoreOne of the options available for reducing NOx emissions is selective catalytic reduction (SCR), used on a number of our engines.

Learn MoreOne of the technologies available for the reduction of oxides of nitrogen (NOx) is exhaust gas recirculation (EGR).

Learn MoreReducing particulates and optimising fuel consumption are primary reasons for adding high pressure common rail to our engines.

Learn MoreIf you're ready to receive trusted advice from a Perkins expert, speak to our team today.

Connect with usOur digital magazine with the latest news, interviews and analysis.

Read moreYour regional Perkins Distributor can provide local, on-the-ground engine support.

Learn More