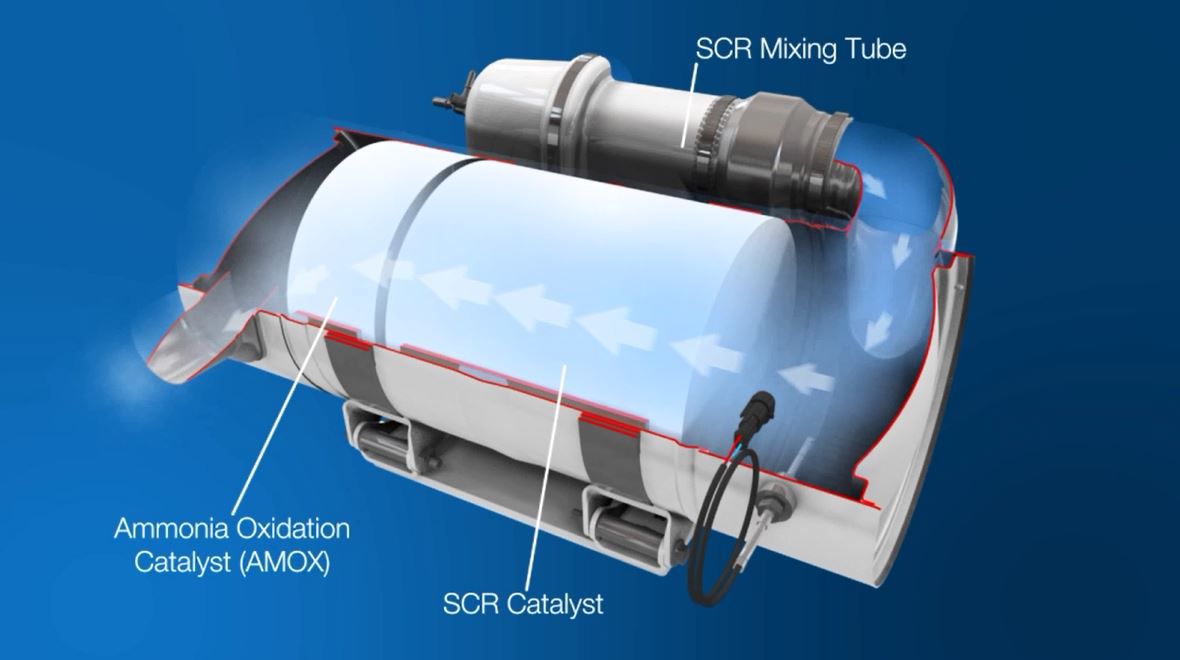

If you’re using a selective catalytic reduction (SCR) system you need diesel exhaust fluid (DEF) for the system to work. Our products that utilise SCR are designed to reduce the amount of DEF in your system. The benefits of this are simple – if customers consume less, they save money. It’s also easier to package, with smaller DEF tanks to be installed and less storage space needed.

The process of selective catalytic reduction (SCR) in our engines is invisible to the operator. The only action required on their part is to ensure the diesel exhaust fluid (DEF) tank is refilled as required.

To keep operator running costs to a minimum, we have minimised the amount of DEF required, as a percentage of the diesel consumed. For our 1200 Series engines utilising SCR, the amount of DEF required is within the range of 3-4 percent of the diesel consumed. For our 854 range of engines that utilise SCR, the amount required is around 3-5 percent of the diesel consumed.

DEF is chemical grade urea in solution. Liquid at room temperature, it is composed of 32.5 percent urea and 67.5 percent de-ionised water.

Operators can use any commercial DEF that meets the ISO 22241 specification in our SCR-equipped engines. They can buy it from a variety of retail locations, such as on-highway truck fuelling stations or automotive parts stores, or they can arrange for bulk delivery from fuel distributors or DEF producers.

Operators will need to consider several factors including the shelf-life, storage temperature and containment requirements of DEF when purchasing it.

The optimal storage temperature for DEF is 15-77°F (-9- 25°C). The rate of decay significantly accelerates when DEF is stored in temperatures above 90°F /32°C. It freezes at 12°F/-11°C.

Exposure to sunlight will reduce the shelf-life of your DEF.

DEF has specific container requirements, and there are restrictions around the kinds of containers that DEF can be stored in. If you’re unsure, please refer to the Perkins Operation and Maintenance Manual (OMM) for more information.

Operators will need to consider these materials when they transfer and handle DEF. If they pump DEF from bulk tanks, they should particularly consider the materials of the funnel and pump used.

Consult your OMM for specific instructions that relate to your engine system.

With our SCR-equipped engines, operators will only need 3 litres of DEF for every 100 litres of diesel fuel

Operators can use any DEF that meets the ISO 22241 specification in our SCR-equipped engines

If you’re using a selective catalytic reduction (SCR) system you need diesel exhaust fluid (DEF) for the system to work.

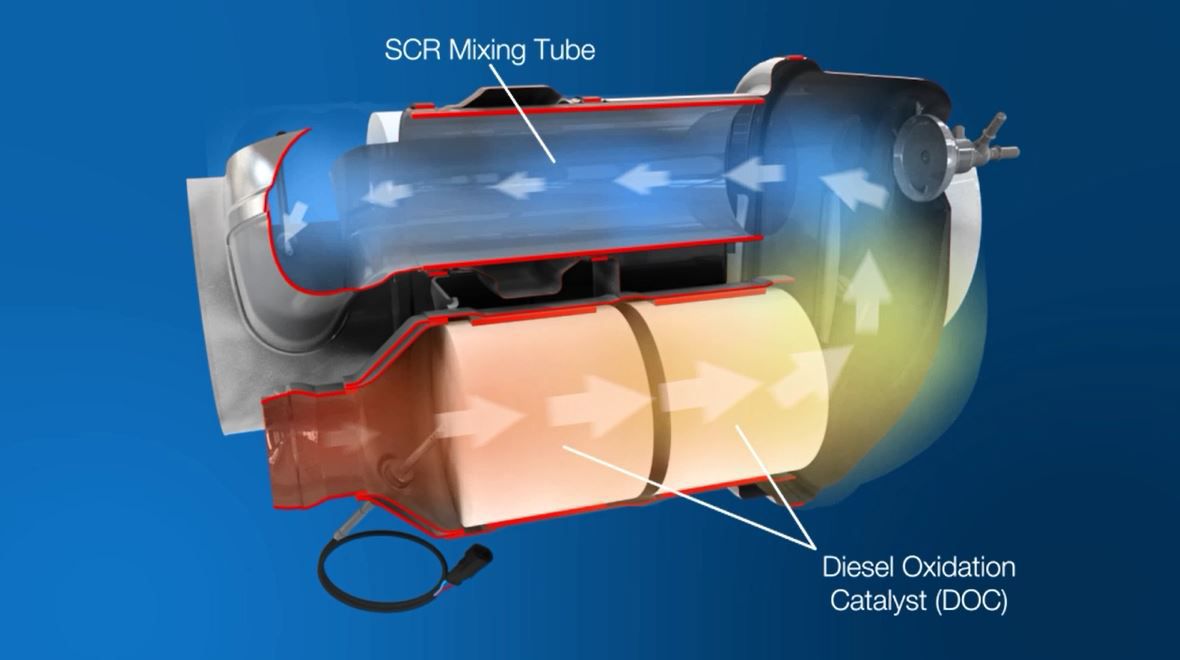

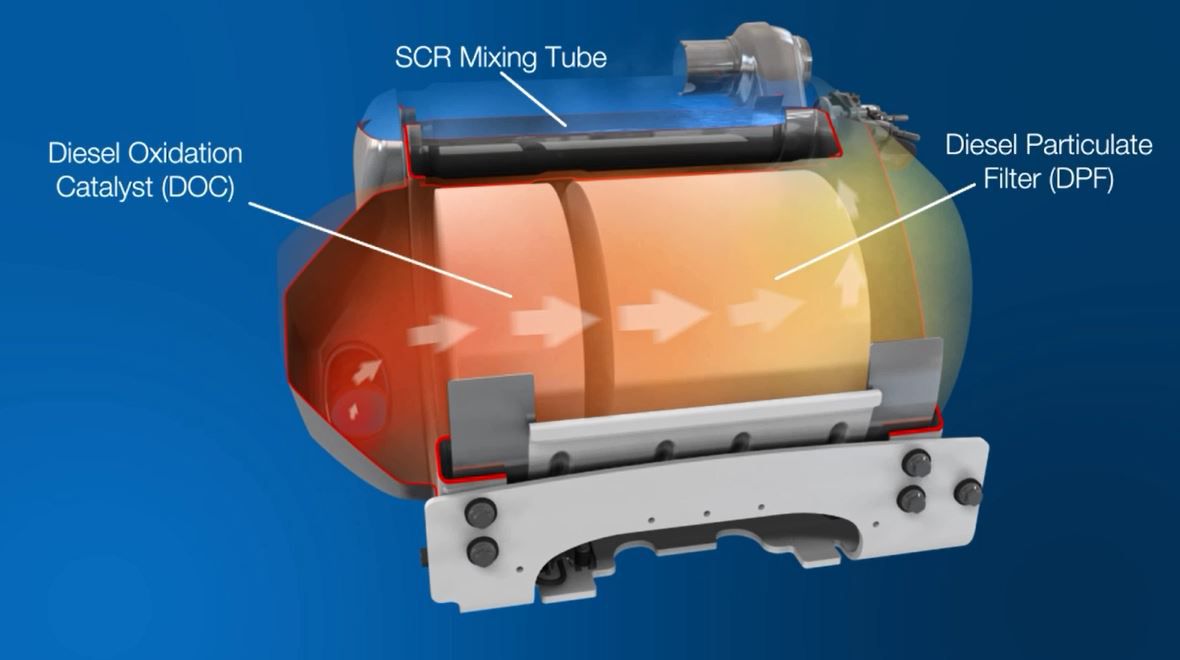

Learn MoreA diesel oxidation catalyst (DOC) is an aftertreatment component that is designed to convert carbon monoxide into carbon dioxide and water.

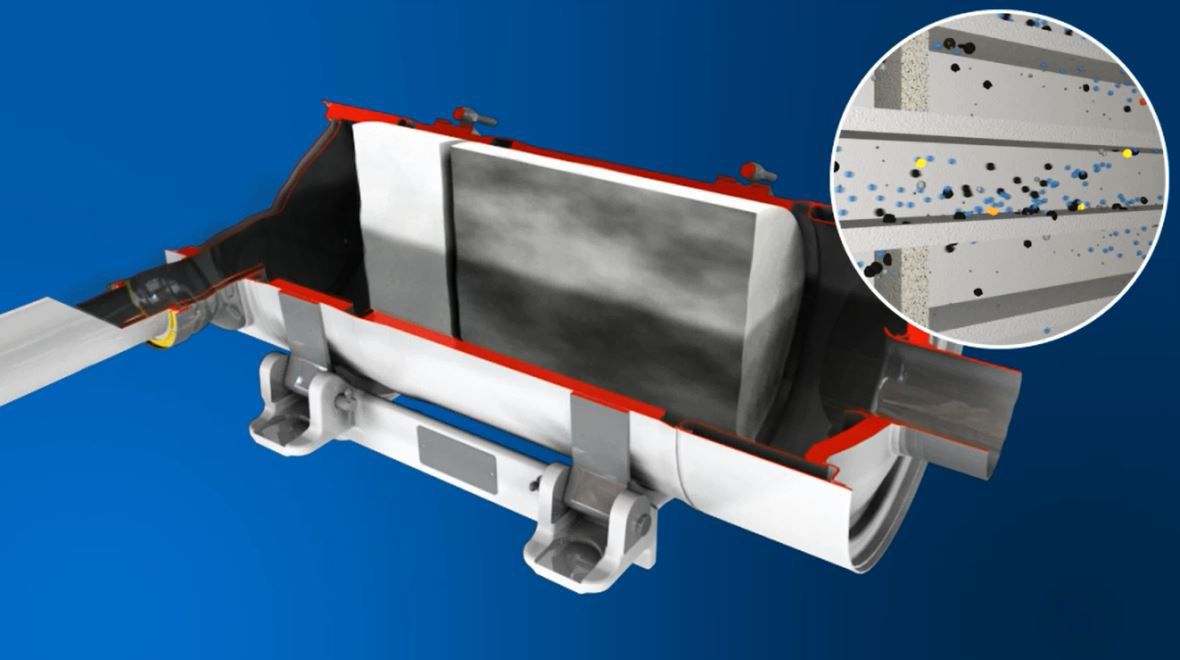

Learn MoreOur diesel particulate filter (DPF) solutions capture a high percentage of particulate matter or soot.

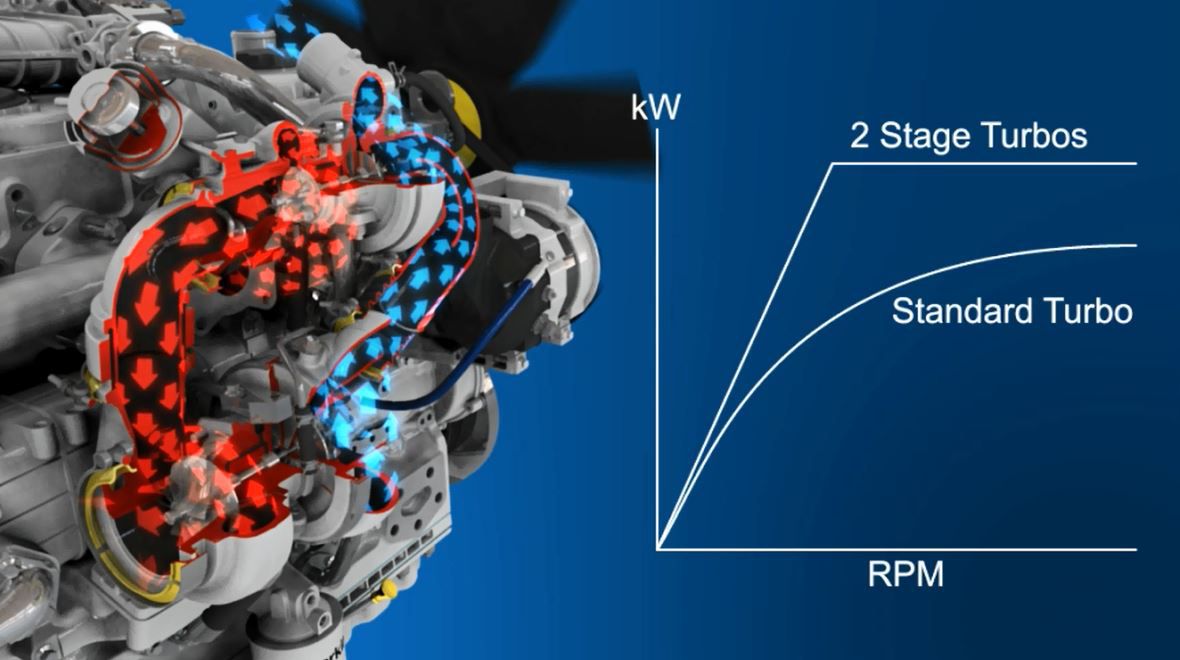

Learn MoreA series turbo set-up involves two turbochargers installed to operate in sequence.

Learn MorePassive regeneration is an approach used to oxidise particulate matter (PM) in the diesel particulate filter (DPF).

Learn MoreOne of the options available for reducing NOx emissions is selective catalytic reduction (SCR), used on a number of our engines.

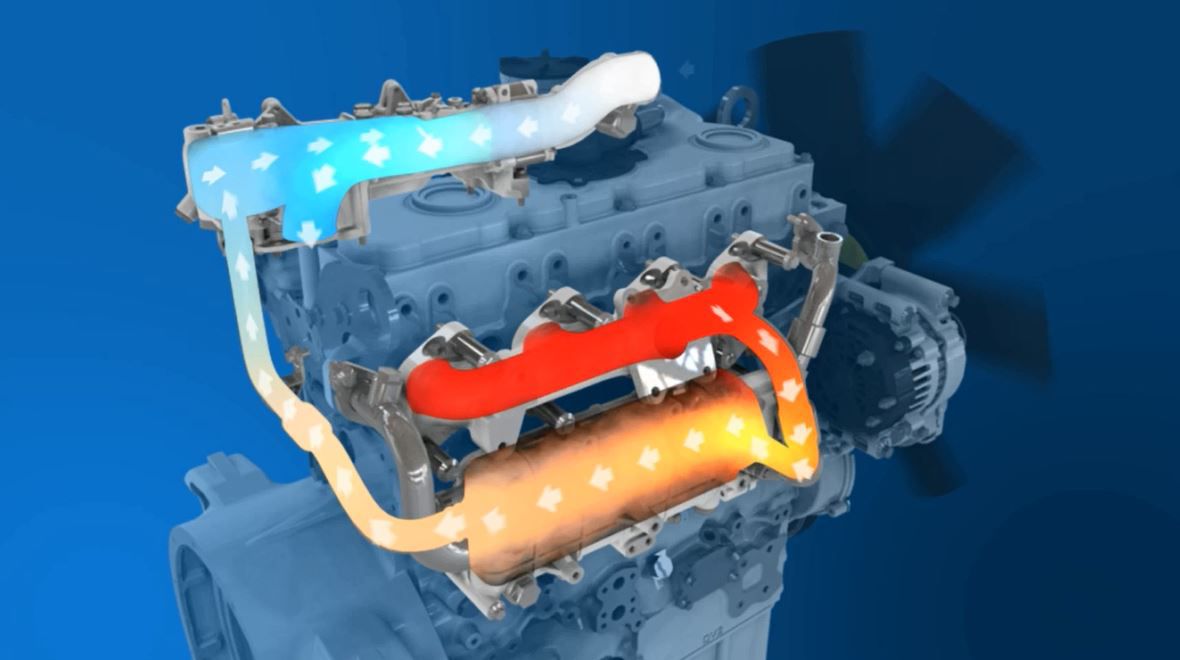

Learn MoreOne of the technologies available for the reduction of oxides of nitrogen (NOx) is exhaust gas recirculation (EGR).

Learn MoreReducing particulates and optimising fuel consumption are primary reasons for adding high pressure common rail to our engines.

Learn MoreIf you're ready to receive trusted advice from a Perkins expert, speak to our team today.

Connect with usOur digital magazine with the latest news, interviews and analysis.

Read moreYour regional Perkins Distributor can provide local, on-the-ground engine support.

Learn More