“I’m really excited about the potential of what our connectivity solutions can do,” enthuses Ronan, “and their ability to understand how products are being operated and used. Our new offering really is a powerful tool that has already been positively received by our pilot customers.”

Over the past year, the Perkins brand has spent significant time, energy and resources to accelerate transformational changes to benefit customers around the world, spanning operations, research and development, product and service offerings including aftermarket support, and the many ways customers interact with and experience Perkins before and after a sale.

Combined, these changes are helping Perkins protect its hard-earned reputation as an industry leader by showing how it is building on its past success to rapidly transform from just a manufacturer of diesel engines for OEMs to a future-forward problem solver serving an array of customers seeking a wide range of advanced power solutions.

Ronan explains: “So we’ve always had our customers and we’ve always had our products, but now connectivity has the ability to pull these so much closer together than ever before, creating an enhanced solution and experience for everyone.”

So how did it all begin? “We’ve spent a considerable amount of time with our customers, as they have to be at the core of any solution that’s implemented,” says Ronan. “We asked our customers who have already connected about their experiences, what they had learned and liked. To those customers who haven’t connected their assets yet, we asked them why they hadn’t and what barriers there were to doing so. And of course we asked both sets of customers how Perkins’ connectivity services could help solve the problems they are looking for answers to or enhance their current solution.

“We will be offering two services, both with the same aim of making digital a key enabler, while providing a superior customer experience and delivering growth for us and our customers.”

The first is a telematics solution, delivered through an new Perkins telematic device, which is simple to connect and will take data from the machine and send it back to Perkins and the customer.

The second solution is Perkins’ Application Programming Interface (API) – an interface enabling data to be passed between two platforms. Ronan explains: “This is useful for those customers that already have a connectivity solution, so we can provide an additional service that they are not getting already. During our research phase we discovered that they were happy to be getting some information, but actually we could provide an enhanced solution – not just data, but enriched data, which is where our solution is going. In this instance, we’re not just providing data from the machine to the back office, but we take the data and enrich it further – and provide actionable insights.

Ronan continues: “So a customer has our proven connectivity services, but what I believe is our real differentiator, is our condition monitoring and advanced analytics. Our condition monitoring team is central to our solution – it’s embedded as part of the service. We take the data and we enhance it. The data we enhance, we then provide insights and recommendations to the customer. That is where this really sets us apart from other solutions, as it’s a much smarter solution.

“We have that knowledge about our engines, that we know better than anyone else. We know when we see a fault code, the best resolution for it and we can advise what that is. Through the condition monitoring team, we can also work with our customers to provide deeper understanding through advanced analytics and will push out these recommendations and insights. We have the advantage of scale because we will be connected to a large and global fleet of equipment, so our insights and analytics are potentially much better. This really is a key differentiator in our connectivity service.

“Additionally, one of the barriers that we understood from our discussion with customers was the support network available to them. At Perkins we already have this service and team in our business, so customers don’t have to invest in this element of the solution, as we make it available to them.”

“We are developing a fully integrated solution,” says Ronan. “People don’t want all these platforms developed in insolation. They want all these things seamlessly linked together. So, in the future, Perkins ecommerce will be fully embedded in our end to end solutions, as we bring together multiple platforms including the Perkins® Hub – for use by distributors and OEMs, Perkins® My Engine App – which with more than 86,000 active users, is already a core part of the connectivity service and Perkins® Fleet Vision – the user interface. It truly is a Perkins ecosystem of integrated elements including service literature, tech support, parts information and recommendations all relating to a selected engine of interest in one Perkins solution.

“Our API and Perkins telematic device hardware will also be part of the full end to end service, fully integrated with the customer very firmly at the core. The way we have created our solution and will roll it out, the data will be shared with all those that help support the customer – such as the OEM, the OEM’s service network and the local Perkins distributor, to make sure the customer receives the best possible service and solution.”

As a global business our OEMs are complex. “They go from large to small, they have different needs and different business types,” explains Ronan, so we had to make an interface that was flexible and adaptable, and which had to reflect the customer’s business.

“Our interface has a hierarchy tree, so it can be quickly built and adapted by the customer, to align with how they do business. Things like unit and/or fleet data, priority data, alarms, events, history – they can be moved around and explored further. They can also create customer alerts, monitor trend data and generate reports.”

Extensive customer pilots across Europe, the Middle East, Africa and Far East have proved “very positive” says Ronan, and “have highlighted the benefits of the Perkins telematic device, the API and the user interface”.

He continues: “OEMs have said that knowing how many hours are on these engines and where they are, have enabled them to pre-empt issues and send alerts to customers. It has provided greater efficiency and has taken away any guess work, with not all faults requiring onsite visits. Now, servicing is happening at right time and for example, if know the fault, the service team arrive with the right parts, so there’s less downtime and issues are often resolved in just one visit.”

The benefits of Perkins connectivity services are:

“Connectivity is really proving itself to be a vital tool for the future,” states Ronan. “Our solution helps move the industry from being reactive to issues, to helping customers have more scheduled maintenance and when there is an issue to be actioned, as we have seen already, the maintenance teams have often been on the ground even before the customer is aware there’s a problem. They arrive prepared after seeing the faults, so they attend with the right parts in the van to reduce downtime and fewer repeat visits.

“We’re excited for the here and now and what we can do for our customers, but rest assured, this is just the start of our connectivity journey as we can quickly scale and will going forward, evolve even further.”

Perkins’ collaboration with Trackunit, delivering real-time insights to customers, increasing productivity in the field.

Read moreFor industrial equipment rental, excellent technical support and parts availability is a necessity.

Read moreTo mark Agritechnica's 'Celebrate Farming Day', Powernews spoke to Andy Curtis, Customer Solutions Director at Perkins.

Read moreClever configuration options fulfil the current and future requirements of the industry.

Read moreWho keeps the lights on when the grid can’t? The power generation sector, of course. In the UK, its interests are represented by The Association of Manufacturers and suppliers of Power generating Systems (AMPS) – whose new director general, Alan Beech, came into post earlier this year.

Learn MoreHave you ever looked at the name of a Perkins engine and wondered what all those numbers and letters actually mean? If so, you’re certainly not alone. But rest assured the nomenclature is anything but random.

Read moreOne alternative fuel option we’ve researched heavily and have accommodated in our diesel engines for more than a decade is hydrotreated vegetable oil (HVO) – which must meet the EN 5940 standard – with the Perkins® 400 to 5000 Series able to use up to 100% HVO.

Read moreIn part two of our spotlight on marine we talk with Ben Lewis commercial manager, Dave Wood, application and tech support team lead and Stuart Phillipson, marine application and tech support to find out more about what’s in development for the marine range.

Read moreWhy stick to one fuel, when you can have a configurable power system?

Read moreMore than just a curiosity, they offer us different routes to future food security.

Read moreThe new Perkins global marketing and channel development director.

Read moreThings are different when it’s very, very cold.

Read moreEngineering manager Graham Hill explains the importance of structural simulation when designing a new engine.

Read moreThe platform will cover two key power nodes.

Read moreInterview with Susterre CEO Michael Cully on the latest no-till soil solutions.

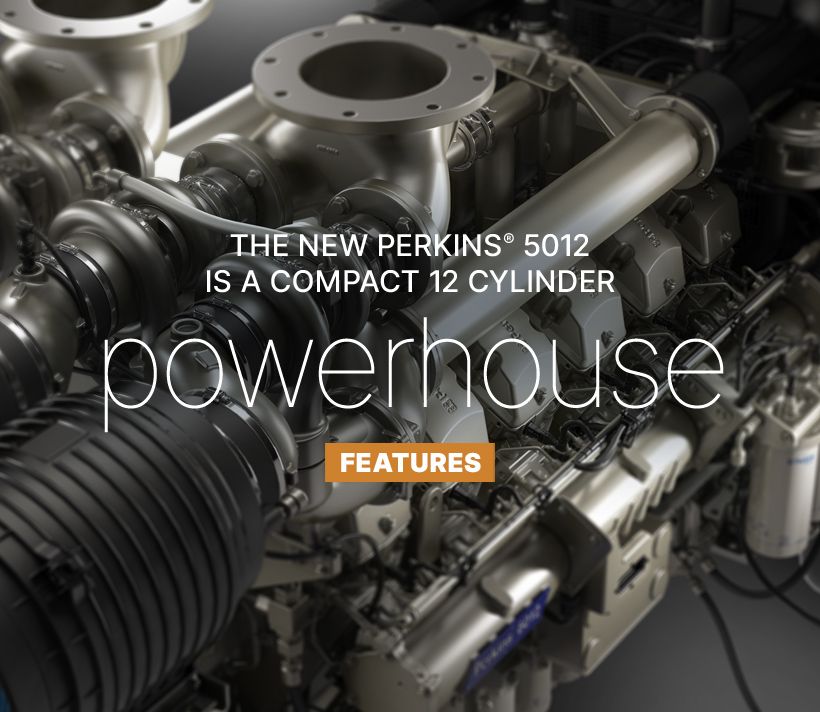

Read moreA compact 12 cylinder powerhouse.

Read moreFor 60 years Lindner has chosen Perkins engines to power its machines.

Read more