Powering ahead in agriculture.

Every second year, it’s time for Agritechnica – the world’s leading trade fair for agricultural machinery. Held over seven days in November, the show brings together manufacturers, innovators and visionaries to present solutions for the challenges of global crop production.

To mark Celebrate Farming Day, one of the show’s theme days, Powernews spoke to Andy Curtis, Customer Solutions Director at Perkins, about providing solutions for perhaps the most pressing of those challenges, power.

How do we keep farmers farming, efficiently, sustainably and with high levels of productivity? Crop production, at the scale needed to feed a global population of up to 10 billion, needs mechanisation – which in turn, demands a reliable source of power.

What should that be? In farming – and it’s important to emphasise that every industry is different – the internal combustion engine (ICE) is here to stay. For every farmer, in any part of the world, it’s an efficient and reliable source of energy, tried and tested over many years. It’s not enough to say that farmers like dependency; they resolutely demand dependency. In farming, when a field needs to be drilled or the perfect harvest window opens, there can be no waiting, no delay – and the near-instant refuelling capability of ICE provides the assurance that a machine can keep going until the job’s done.

At Perkins, we’ve designed and built engines to fulfil that function for 95 years. But our belief in a future for ICE shouldn’t be seen as us burying our heads in the sand. Instead, we see an opportunity to use ICE as the gateway to a sustainable future for power, by deploying the innovative thinking that’s been a hallmark of Perkins throughout our history, and helping farmers to find simple, easy-to-adopt ways to tackle the energy demand.

Project Coeus

This is perhaps one of our most exciting projects. It addresses the evolving energy landscape – a global commitment to shift from fossil fuels to lower-carbon or zero-carbon energy sources – head-on.

One of the (many) charges levelled against fossil fuels is how reliant we’ve become on them. A single fuel source does not make for a resilient energy system. But the evolving energy landscape gives us the opportunity to redesign our energy systems from scratch. So for ‘Global Energy Systems 2.0’, the intention is to ‘spread the load’ with a portfolio of novel fuel sources, all sporting robust renewable credentials.

That’s exactly what Project Coeus is about. Supported by a £11.14m UK Government grant and named after the Greek god of resolve and intelligence, Coeus exemplifies Perkins new ‘customer-back approach: we’re thinking about the problems faced by the end-user and how we can help solve them.

Launched two years ago, Coeus is committed to developing a ‘drop-in’ hybrid power unit. The drop-in aspect is important: it’s a direct replacement for a diesel-powered equivalent, with the same if not better performance.

For an OEM, this reduces almost to zero the engineering and design challenges associated with a new power source, such as system design integration, installation validation and analysis and improvement (A&I) demands – all of which Perkins supports through resources such as the Customer Machine Engineering Team (CMET).

But perhaps the most exciting aspect of Coeus lies in its fuel source: not just one, but several. First, by designing an engine with complete fuel flexibility, we can help support the creation of a more resilient global fuel system that allows customers to use different fuel types with minimal disruption to their operations.

Equally exciting is the ability for farmers to self-generate the fuel they’ll use in the future. Bio-methane – one of the four fuels on which Coeus is founded, alongside ethanol, methanol and hydrogen – can be produced on-farm in a multitude of ways, from dairy methane to anaerobic digestion of harvest by-products.

Coeus still has another two-and-a-half years to run, but 2026 should see the launch of an advanced prototype – a hydrogen-fuelled ICE element matched with the hybrid motor and powertrain – to go into full-scale, real-world testing.

Hybrid solutions

We don’t need to wait for Coeus to complete to know that a hybrid engine is already a viable solution.

We’ve worked closely with OEMs to understand two crucial concepts: the operating cycle of real customer machines and the space available in these machines for power systems.

What we know is that there are multiple possibilities for technology configurations in off-highway machines, including those used in agriculture. Machine type and use will dictate the balance between installation complexity, cost, durability, productivity and fuel consumption. On the latter, the critical characteristics are the quantity of energy storage and how quickly it can be released.

Our best demonstration of how all these points can be successfully reconciled lies in the hybrid telehandler project where we took a popular telehandler, refitted it with hybrid technology – and increased its fuel efficiency by 10%.

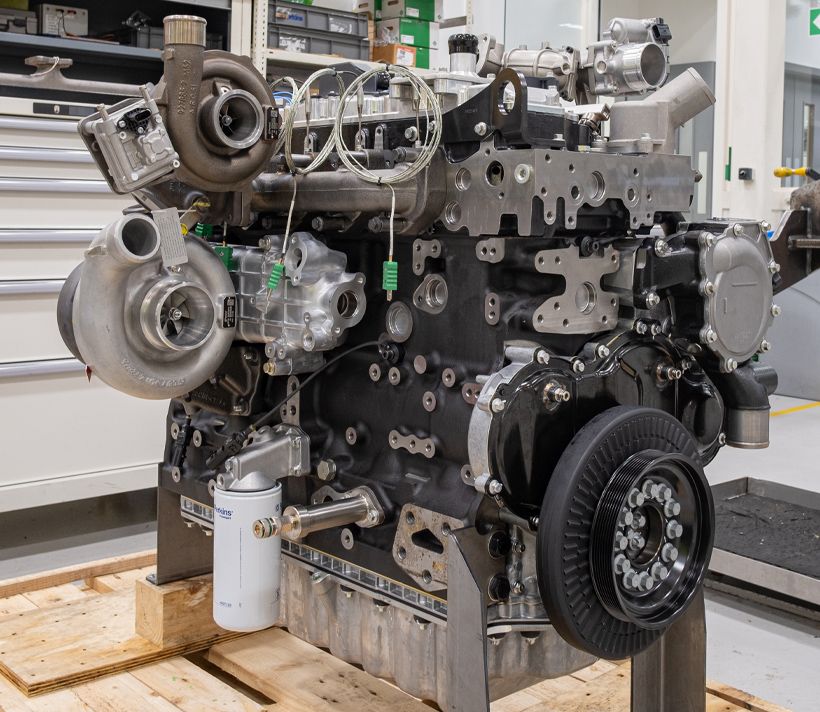

A true test of Perkins’ engineering capability, our team refitted a 75 kW telehandler with a 55 kW Perkins® 904J-E28T, a 20 kW 48V P2 Motor Generator Unit (MGU) and a 48V 3.9 kWh battery – all within the same engine compartment.

Now in day-to-day operation around the Peterborough site, this proof of concept displays a 10% increase in efficiency against the original base machine. Thanks to electric-only running, it can perform additional tasks indoors – making it even more useful than the original specification machine.

What’s more, the machine has been tested in the real world too, with real-life operators. When feedback includes ‘operation felt identical to the diesel machine’, ‘no noticeable transition between engine and motor’, and ‘positive impression’, we know we’re on the right path.

Connected assets

The advanced control systems required to support a hybrid or Coeus platform engine also provide a magnificent opportunity to leverage those to even greater use.

We’ve had Perkins connectivity and condition monitoring in development for a few years – and 2025 saw it move to the real world.

Not just in farming, but in other off-highway sectors too, operators are concerned with minimising both total cost of ownership (TCO) and machine downtimes, while maximising efficiencies in machine management.

By taking the on-board monitoring systems one stage further – adding connectivity – we can effectively deploy a pro-active maintenance regime on any machine. We’ve collected huge amounts of data – terabytes – that reveal what engines are doing and how they’re performing. Using this data to compare with the real-time information provided by the machine uplink means we can keep an engine running not only at peak performance but also spot problems before they become critical.

In farming, that translates into the difference between a combine that keeps running through harvest, versus one that breaks down with only a third completed. That same data also helps us to guide new product development or new services, further adding value to the customer experience.

Machine diversity

Finally, it’s worth emphasising that it’s not only diesel on which we should become less reliant. We should also not allow conventional thinking to constrain future thoughts about how we should use and deploy machines.

For example, conventional thinking dictates that to plough a field, one needs a tractor, implement and operator. But in a world where labour is ever more costly, and the operator might be better upskilled to another role, could an autonomous tractor be a better bet?

There’s similar thinking on power. Current prices of diesel, batteries and grid electricity limit the economic case for fully electric machines. However, electric machines might find niche operations: such as a wheeled loader (which could also be autonomous) around the farmyard, recharged by solar panels on the grain store roof.

Ready for the future

What all these examples prove is that while we’re committed to a future where the internal combustion engine still features, we’re also ready for a future filled with other technologies. What’s more, this isn’t just blue-sky thinking: in projects like the hybrid telehandler, we have not just proof of concept, but real-life proof from real-life usage.

Even more so, we’re already in our future: every Perkins engine that rolls off one of our production lines in the UK, US, Brazil, China and India can run on biodiesel and hydrotreated vegetable oil (HOV)). At Perkins, our solutions for the evolving energy landscape are already in full swing.

-

Connectivity delivers real-time insights

Perkins’ collaboration with Trackunit, delivering real-time insights to customers, increasing productivity in the field.

Read more -

Rental equipment runs on uptime

For industrial equipment rental, excellent technical support and parts availability is a necessity.

Read more -

New marine propulsion engines

Clever configuration options fulfil the current and future requirements of the industry.

Read more -

Meet AMPS’ new Director General, Alan Beech

Who keeps the lights on when the grid can’t? The power generation sector, of course. In the UK, its interests are represented by The Association of Manufacturers and suppliers of Power generating Systems (AMPS) – whose new director general, Alan Beech, came into post earlier this year.

Learn More -

Unlock the mystery of Perkins engine names

Have you ever looked at the name of a Perkins engine and wondered what all those numbers and letters actually mean? If so, you’re certainly not alone. But rest assured the nomenclature is anything but random.

Read more -

Flexible fuel choices – HVO

One alternative fuel option we’ve researched heavily and have accommodated in our diesel engines for more than a decade is hydrotreated vegetable oil (HVO) – which must meet the EN 5940 standard – with the Perkins® 400 to 5000 Series able to use up to 100% HVO.

Read more -

Spotlight on marine – new product introduction

In part two of our spotlight on marine we talk with Ben Lewis commercial manager, Dave Wood, application and tech support team lead and Stuart Phillipson, marine application and tech support to find out more about what’s in development for the marine range.

Read more -

A flexible hybrid power system

Why stick to one fuel, when you can have a configurable power system?

Read more -

Rediscovering the world’s ‘lost crops’

More than just a curiosity, they offer us different routes to future food security.

Read more -

Spotlight on marine - customer first

Perkins marine engines has an illustrious history. Meet the team behind the brand.

Read more

Also in this issue

-

Connectivity delivers real-time insights

Perkins’ collaboration with Trackunit, delivering real-time insights to customers, increasing productivity in the field.

Read more -

Rental equipment runs on uptime

For industrial equipment rental, excellent technical support and parts availability is a necessity.

Read more -

New marine propulsion engines

Clever configuration options fulfil the current and future requirements of the industry.

Read more