The new Perkins® 5012 is a compact 12 cylinder powerhouse.

Perkins broke new ground in 2022 with the introduction of the Perkins® 5000 Series, its first full authority electronic engines optimised and purpose built for power generation applications. Initially offered in 6 and 8 cylinder in-line configurations, the 5000 Series now includes a compact vee 12 cylinder, 46 litre model – the Perkins® 5012.

The 5012 is rated at 1275 to 1500 kVA and 1710 kVA in 50 Hz prime applications and 1250 to 1500 kW as a 60 Hz critical standby powerplant. It’s certified as U.S. EPA Tier 2 compliant and is Tier 2 capable outside the U.S.

The next generation of electric power.

Perkins engines have been a go-to choice for electric power generation around the world for many decades. All of that real-world experience, research, development and testing was the foundation that the 5000 Series development team built upon.

They were challenged to re-imagine everything that goes into an efficient, reliable, durable and economical electric power engine with a clear focus on meeting contemporary environmental concerns. The Perkins 5000 Series is the result.

Perkins engineers examined, evaluated and enhanced everything from the core architecture and individual components down to sealing technology and even individual bolt patterns to design an engine specifically optimised for power generation. The result is a family of engines with outstanding load acceptance, future-proof emissions, high power density, built-in reliability and durability, and a low total cost of ownership. The new, Perkins 5012 is no exception.

Outstanding load acceptance.

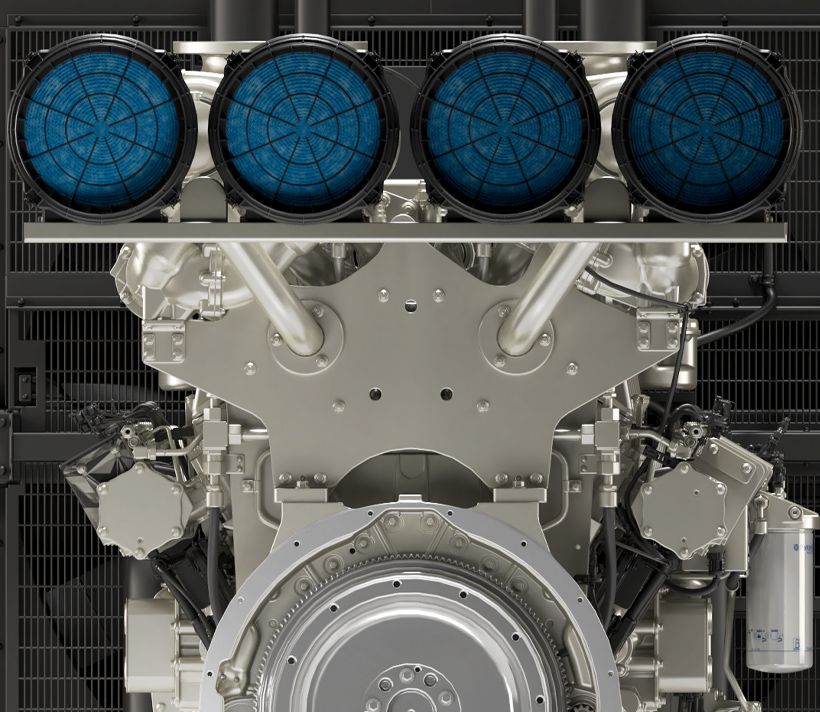

Like all 5000 Series engines, the 5012 is engineered to meet ISO G3 and NFPA110 standards to handle the most demanding load acceptance challenges. The 5012 uses a pair of smaller turbochargers on each bank that get up to speed much faster than a single large unit.

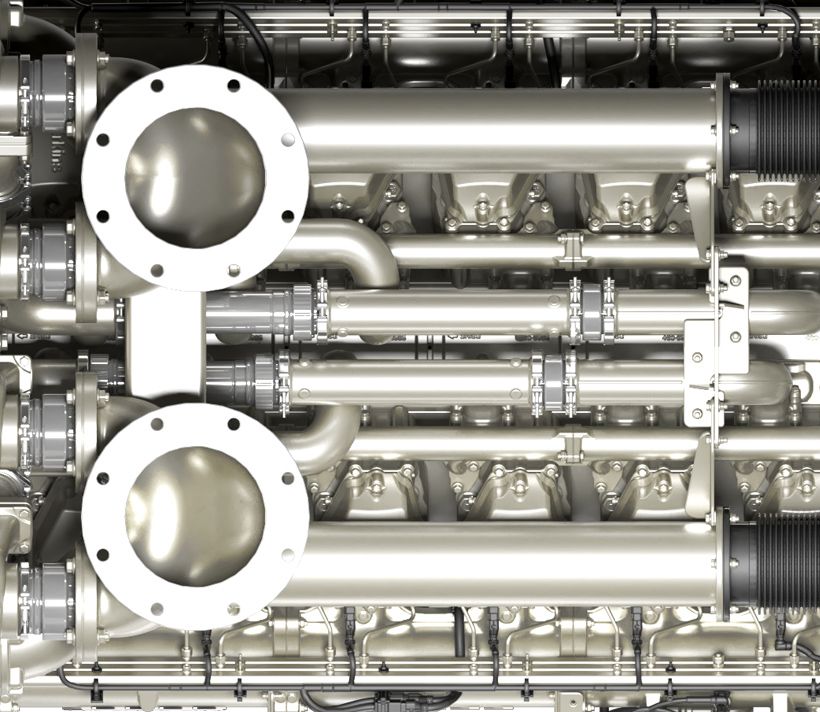

Even the exhaust manifolds are engineered to optimise gas flow to the turbochargers which further reduces ramp-up time and enhances load acceptance.

The result: the engine delivers excellent transient response time and outstanding load acceptance.

Future-proof emissions.

The 5012 variant uses a unique, low-pressure fuel system developed specifically for the 5000 Series that is more tolerant of variations in fuel quality. The 5012 is fully compatible with biodiesel mixtures up to B20 and can operate on 100 percent hydrotreated vegetable oil (HVO) to meet present and future lower-carbon fuel requirements*.

High power density.

The Perkins® 5012 is a purpose designed engine optimised with the latest technology to operate at top efficiency over its full rated output range. It is physically smaller than legacy engines with similar output, making it an ideal choice for space-limited applications.

The V12 configuration provides a significant increase in power over the in-line 6 and 8 cylinder 5000 Series engines in a compact package that is easily integrated into prime and standby systems. It’s an ideal solution for hospitals, data centres and other locations where space is limited, but reliable power is essential.

Built in reliability and durability.

The pistons, rings, liners, fuel filters, the electric fuel priming pump and the electronic fuel system used in the 5012 are all engineered specifically for the 5000 Series. More than 200,000 engineering hours went into their development, and 10,000 hours of real-world testing have demonstrated their durability and reliability.

Low total cost of ownership.

Every component of a 5000 Series engine was chosen to maximise uptime while reducing operating and maintenance cost. In the 5012, for example, the pistons, rings and liners are specifically designed to work together to minimise both wear and oil consumption. The 5012 engine is also equipped with an electric fuel priming pump and premium fuel and oil filters to achieve an oil and fuel service interval up to 500 hours or two full years.

Responsive power when you need it.

The Perkins 5012 uses a proprietary adaptive cylinder cut-out and cranking protocol to deliver an outstanding cold-start capability. In conjunction with the 5000 Series’ sophisticated turbocharging technology, electric fuel priming pump, and electronic fuel system, the 5012 can deliver 100 percent power within 13 seconds of a cold start.

The electronically controlled injectors used on the 5012 can alter both timing and pressure to accommodate a broad range of ambient temperatures and altitudes without sacrificing performance. Working together with the advanced turbocharging technology developed for the 5000 Series the combination has been proven to help optimise load acceptance, altitude capability and fuel consumption.

As a full authority electronic engine, the Perkins 5012 features an electronic control module (ECM) and sensor pack that is easily integrated into existing monitoring and control ecosystems. This makes the 5012 exceptionally easy to seamless incorporate into many different telematic systems regardless of current infrastructure.

Because downtime is never an option.

Hospitals, data centres and other mission-critical installations require dependable, reliable, robust prime and backup power. Downtime simply isn’t an option, and the Perkins 5000 Series has been engineered, tested and proven to meet the challenge.

With the addition of the more powerful 5012 V12 – which will be built in Stafford, UK and Aurangabad, India – the choice is clearer than ever. The 5012, the newest member of the 5000 Series joins the next generation of electric power, and it’s ready to go to work.

* Fuels must meet the specifications and characteristics described on www.perkins.com in order to be used in Perkins engines and reduce the risk of downtime.

-

Connectivity delivers real-time insights

Perkins’ collaboration with Trackunit, delivering real-time insights to customers, increasing productivity in the field.

Read more -

Rental equipment runs on uptime

For industrial equipment rental, excellent technical support and parts availability is a necessity.

Read more -

Powering ahead in agriculture

To mark Agritechnica's 'Celebrate Farming Day', Powernews spoke to Andy Curtis, Customer Solutions Director at Perkins.

Read more -

New marine propulsion engines

Clever configuration options fulfil the current and future requirements of the industry.

Read more -

Meet AMPS’ new Director General, Alan Beech

Who keeps the lights on when the grid can’t? The power generation sector, of course. In the UK, its interests are represented by The Association of Manufacturers and suppliers of Power generating Systems (AMPS) – whose new director general, Alan Beech, came into post earlier this year.

Learn More -

Unlock the mystery of Perkins engine names

Have you ever looked at the name of a Perkins engine and wondered what all those numbers and letters actually mean? If so, you’re certainly not alone. But rest assured the nomenclature is anything but random.

Read more -

Flexible fuel choices – HVO

One alternative fuel option we’ve researched heavily and have accommodated in our diesel engines for more than a decade is hydrotreated vegetable oil (HVO) – which must meet the EN 5940 standard – with the Perkins® 400 to 5000 Series able to use up to 100% HVO.

Read more -

Spotlight on marine – new product introduction

In part two of our spotlight on marine we talk with Ben Lewis commercial manager, Dave Wood, application and tech support team lead and Stuart Phillipson, marine application and tech support to find out more about what’s in development for the marine range.

Read more -

A flexible hybrid power system

Why stick to one fuel, when you can have a configurable power system?

Read more -

Rediscovering the world’s ‘lost crops’

More than just a curiosity, they offer us different routes to future food security.

Read more

Also in this issue

-

From engine insights to issue resolution

The customer benefits achieved through Perkins’ new connectivity solutions.

Read more -

Meet new marketing director, Vicki Reeves

The new Perkins global marketing and channel development director.

Read more -

The chill factor

Things are different when it’s very, very cold.

Read more -

Structural engineers are key players for Perkins

Engineering manager Graham Hill explains the importance of structural simulation when designing a new engine.

Read more -

The new Perkins® 2806FA CPCBIV+

The platform will cover two key power nodes.

Read more -

The pressure's on

Interview with Susterre CEO Michael Cully on the latest no-till soil solutions.

Read more -

Double anniversary underlines powerful collaboration

For 60 years Lindner has chosen Perkins engines to power its machines.

Read more