There is an optimum temperature at which your Perkins engine needs to run to maximise its efficiency and prolong its life. The cooling system – which is made up of several different but complementary components – is vital in preventing engines from over-heating and breaking down.

Every engine needs some form of cooling system to prevent it overheating and breaking down. The term cooling system in a water-cooled engine generally refers to a combination of the radiator, fan, thermostat, and the water pump which connect to passages in the engine and they are all designed to work in harmony to remove the very high levels of heat generated as part of the combustion process.

The cooling system is usually fitted when a new engine is built by the machine builder or OEM, though sometimes it can be provided by the engine manufacturer complete as a unit. As the cooling system is a major element to the performance of the engine, we take the specification of the best and most effective cooling system seriously. Our application engineering teams, working with the machine builder, sign off the use of the most appropriate cooling system that has been designed for the application, which is why the use of genuine Perkins components will ensure the smooth and efficient use of your engine.

Most engines have radiators to disperse heat. Their design incorporates as large a surface area as possible and the tubes within them are arranged in long loops to add to the area available. Water that has travelled through the engine flows into these tubes where the heat is lost, often with the aid of a fan to help the cooling process.

The water pump circulates this water in a continuous loop, feeding cold water into the engine and removing heated water on its way out. On average, an engine water pump will move a greater volume of water in a day than a domestic washing machine will use in five years, so it needs to be very reliable.

The oil within the engine has Its main function to provide lubrication to the moving parts of the engine, but just as important is its role in circulating and dissipating the heat from the oil that is produced when the engine runs.

Because these individual parts are used together to create the cooling system, any broken parts can be replaced individually too. All our genuine parts are designed to meet very high tolerances.

Engines that run too hot are in danger of overheating and causing damage to internal components. But there are also difficulties if the engine fails to get up to the correct operating temperature, in under-performance and increased fuel consumption.

Buy orginal Perkins ecooling systems from Perkins (US and UK)

The use of non-genuine parts in your Perkins engine can be a false economy. Cheaper substitute parts can wear faster, may damage other parts of the engine, and can invalidate your warranty.

The water pump is designed specifically for the model of engine you have. Each one has undergone extensive testing during the development phase to ensure it works time after time and delivers the right amount of coolant flow. A replacement water pump is quick to source, so replacing it before it fails could prevent downtime later. All this is backed by the Perkins warranty.

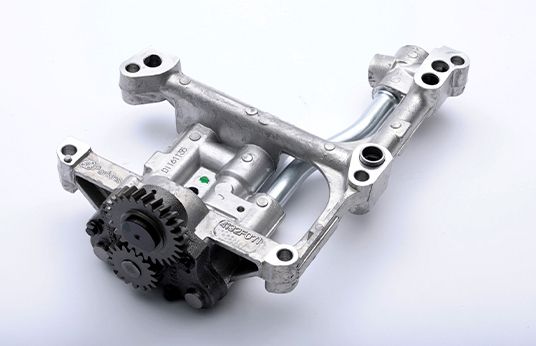

Learn MoreThe oil pump plays an essential role in keeping your engine properly lubricated. It’s a complex piece of engineering that not only keeps everything running smoothly, but also helps with removing excess heat from pistons, bearings and shafts. If it doesn’t work properly and consistently, the engine can potentially seize, causing considerable additional expense and unnecessary downtime.

Learn MoreThermostats are essential for regulating the flow of coolant around the engine. Fitting a non-genuine thermostat could potentially cause your Perkins engine to overheat and seize up, or for it to run at too low a temperature. The thermostat is essential to prevent an engine from overheating or overcooling so that it works as efficiently as possible at all times.

Learn MoreIf you're ready to receive trusted advice from a Perkins expert, speak to our team today.

Connect with usOur digital magazine with the latest news, interviews and analysis.

Read moreYour regional Perkins Distributor can provide local, on-the-ground engine support.

Learn More