Maintenance

Looking after your Perkins engine.

At Perkins, we build our engines to last. Designed for agriculture, their heavy-duty construction and precision engineering ensures that whatever you demand of them, they’ll perform their duty without complaint.

And just as we’ve built them to withstand all that you can throw at them, we’ve also tried to optimise their service intervals. Reduce the time in the workshop, we thought; increase the time spent using the machine to do the tasks needed for you and your business.

But while service intervals come and go, it’s what you do in between that really counts. Get more still from your Perkins engine by practising a little ‘inter-service’ maintenance. You’ll do more than extend its operational life – you’ll also reduce the likelihood of something unexpected between services, and perhaps even the cost of the service itself. You’ll also keep your power output at maximum – it can fall by 20 percent before an operator begins to notice.

Your operating manual explains how to carry out daily, weekly and yearly checks – download one here if you no longer have yours, or use the free Perkins® My Engine App.

Here’s a few pointers from our engineers.

1. Breathe in…

Ever thought about how much air your engine needs to function properly? Take our Perkins® Syncro 3.6 as an example. Delivering 100 kW (134 hp) and up to 500 Nm of torque, at 2,000 rpm its four cylinders will consume around 3,600 litres of air every minute. Think about this engine running all-day in a telehandler, shifting bales during harvest, and we’re looking at nearly 30,000 litres – all of which has to first pass through the air filter. Impair the efficiency of that filter in any way – dust and debris – and the engine suffers too.

Keep the air filter clean. Check it regularly.

2. And breathe out…

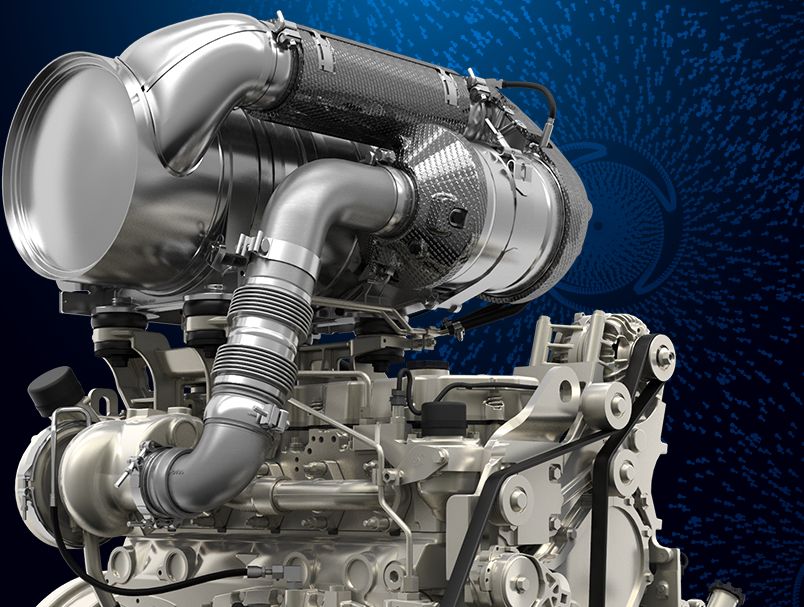

If your engine’s fitted with an emissions control system, it’s important to add this to the regular maintenance schedule. At Perkins, we use a variety of emissions control technologies across our engine range, including selective catalytic reduction (SCR), diesel oxidation catalyst (DOC), diesel particulate filter (DPF) and exhaust gas recirculation (EGR).

If your engine features SCR, it’s important to keep the diesel exhaust fluid (DEF) topped up. If the engine runs out of DEF, it will automatically limit its power and performance to maintain emission control.

DOC is fitted to all of our EU Stage IV and V/U.S. EPA Tier 4 Final engines. Often found in conjunction with SCR technology, it requires no additional control from the machine operator.

A DPF captures the fine particulate matter (PM) that forms during diesel combustion. It also helps lower fuel consumption and improves engine performance, while minimising operating costs. Depending on the DPF model fitted, it can either be cleaned (usually by the dealer), replaced, or can last for the lifetime of the engine.

EGR reduces emissions of oxides of nitrogen (NOx). Cleaning of the valve should only be required during service intervals – but again, a drop-off in performance will be one of the first signs of a blocked EGR valve.

3. Keep cool

If you’ve found the air filter needed a clean, then your radiator needs one too. Plant debris, insects and dust will all decrease the radiator’s efficiency. Clean it out with an air hose – you’re less likely to damage the fins than if you use a water jet.

While you’re looking at the radiator, check the fan belt for tightness.

When did you last check the coolant? If you’ve been topping it up with water alone, then the mixture’s likely to have become diluted. Keep a ready-made mixture of coolant and water to hand, and use this for topping up. It’s best to use deionised water; this will prevent limescale forming, which could lead to blockages in the cooling system.

4. Look after your fuel

Not all diesel fuels are created equal. Source and buy the highest quality you can find. Diesel fuels are rated by their cetane content, the higher the better. Higher grades will perform better, especially in more recent engines – EU Stage III/U.S. EPA Tier 3 and later.

Check your engine’s fuel filter – is it clean and drained? Minimise the risk of water in the fuel by keeping the fuel tank topped up, preventing condensation from forming.

5. Warm-up before exercise

Don’t expect your engine to provide you with peak performance from the moment you fire it up. Asking too much from the engine before it’s reached optimum operating temperature could cause premature wear of components. But warming-up doesn’t mean letting it idle in the yard; a gentle drive at low revs for five minutes will be sufficient to bring it up to temperature and ensure that lubrication is well-circulated.

Just as important is running down the engine before turning it off, especially when a turbo’s fitted and it’s been working hard. Allow five minutes of idling to allow the turbo to cool and prevent hot oil from carbonising.

6. Speaking of oil…

Checking the oil level is probably second-nature, but remember it needs to be done when the engine’s level, and cold. The oil’s not just there for lubrication (although that’s a vital role it plays), but also for cooling.

Use the right type of oil and don’t buy on price alone. Perkins has developed its own oil for use in our engines, Perkins® DEO 15W-40 API CI-4, but other oils are available and suitable, provided they meet the full specification.

7. When winter comes…

What does your Perkins engine power? While a tractor will be used year-round, if the engine’s in a piece of machinery that spends part of the year dormant, it’s worth spending some time preparing the engine for storage.

We’d recommend adding a fuel stabiliser to prevent the fuel from going “off”, ensuring the oil level’s correct, and checking the coolant and anti-freeze concentration.

Perkins engines are designed to keep going. With the regular care and attention we’ve outlined above, you’ll be likely to spot any major problems before they develop into costly repairs. But to help you with identifying any early warning signs, here’s a handy guide to the most common engine problems. Download it, print it, put it on the wall of the workshop and share it with your team.

And for any further information, or queries about your engine, your local Perkins distributor is always well-placed to help with the advice and technical services needed to keep your engine in prime condition.

Perkins. We put power into farming.

-

Request Consultation

If you're ready to receive trusted advice from a Perkins expert, speak to our team today.

Connect with us -

Powernews Q4 2025

Our digital magazine with the latest news, interviews and analysis.

Read more -

Distributor locator

Your regional Perkins Distributor can provide local, on-the-ground engine support.

Learn More