Meet Ann Brown – Vice President of facility operations.

Running four manufacturing facilities in China, the U.S., Brazil and the UK is a welcome challenge for Ann Brown who has held the post of Vice President of facility operations since 2018. Powernews caught up with Ann to learn more about her responsibilities, motivations, and leadership journey.

Ann, many thanks for taking the time to meet with us today. Can you tell us a little more about your current role and how this helps our customers?

Absolutely. As Vice President of facility operations, I have the pleasure and responsibility of running our four global facilities in Wuxi China, Griffin, U.S, Curitiba, Brazil and Peterborough, UK. These facilities manufacture engines from 0.5 up to 7.1 litres for our Perkins powered customers around the world.

Having a global team, it’s important for me to focus on building a strong operational foundation by emphasising safety, quality, Lean principles, and cost-effectiveness. I work closely with many areas of our business, as well as suppliers, and of course our customers and distributors, to ensure the delivery of the world-class products they need for their equipment.

It sounds like it keeps you very busy, but I’m intrigued by what brought you into this industry in the first place?

I decided to join Caterpillar – which acquired the Perkins brand in 1998 – primarily based on the positive experience I had during my year-long industry placement at another of its brands, then known as FG Wilson. That valuable experience provided me with insights and knowledge, and I thoroughly enjoyed collaborating with the talented individuals there.

After completing my university education, I secured a position at a pharmaceuticals company in Northern Ireland, and I attribute much of my success in obtaining that role to the experience I gained during my FG Wilson placement.

During my time at the pharmaceutical company, I found myself in a work environment that required teamwork, team trust, and mutual support. It was a rewarding experience that reinforced my aspiration to be part of a collaborative team where I could contribute my skills and continuously advance in my career.

When the opportunity arose to join Caterpillar, I saw it as an opportunity to be part of an organisation and team that would allow me to leverage the skills I had acquired and further develop my career. Since then, it has been an incredible journey, and time has flown by as I have experienced personal and professional growth within the company.

Overall, my decision to choose Caterpillar was influenced by the positive experiences I had during my industrial placement from university, my desire to work within a supportive team, and the opportunity to continue advancing my career within a reputable and globally recognised organisation.

Since joining the company, have you always worked in the manufacturing area?

In short, no, but I guess you want a slightly longer answer than that! So, throughout my career, I have held various roles in different areas of expertise. With over 25 years of experience, I have developed a multi-role background in supply chain, purchasing, operations, sales, product-commercial, and aftermarket support, primarily within the diesel power generation industry.

In recent years I have also taken on the responsibility of order to delivery for four of our global engine manufacturing facilities, which is my current role we’ve just been talking about.

I recently spoke to the new marketing director Vicki Reeves and what’s evident from my conversations with both of you, is your passion for your respective jobs and getting things done. Is this what motivates you?

Yes, throughout the various roles I’ve had, I have aways been driven by a passion for achieving high performance, managing cross-functional teams, and delivering results.

I have thoroughly enjoyed every role I have held throughout my career. Each position has provided me with unique opportunities and valuable experiences. One of the aspects I particularly appreciate about working for Caterpillar is the global nature of the company. It has allowed me to interact with exceptional individuals and teams from various countries around the world. Being part of a global business has given me the privilege to travel extensively, visiting over 20 countries as part of my day-to-day work. This exposure has broadened my horizons and provided me with a deeper understanding of different cultures, perspectives, and business practices. It has been truly enriching to meet and collaborate with people from diverse backgrounds, learning valuable lessons along the way.

Do you have a particular piece of advice for people either at the start of their careers or mid-career?

One thing I strongly believe in is lifelong learning. Each day presents a new opportunity to grow, change, and develop oneself, whatever stage you’re at in your career journey. The dynamic nature of the roles I have held has allowed me to continuously learn and adapt, keeping me engaged and motivated.

Overall, I consider myself fortunate to have had the chance to work in a company like Caterpillar, where I have been able to contribute, learn, and thrive in a global environment surrounded by talented individuals.

Many thanks for your time, Ann, but before you go, I have one final question. With such a busy, global role, how do you manage to achieve what you consider to be a work-life balance?

In today's evolving work landscape, achieving a healthy work-life balance has become increasingly important. When I first began my career, the concept of work-life balance was not commonly discussed or prioritised. The traditional mindset was to work diligently and steadily advance in your chosen field. However, the dynamics have shifted over time, and now there is a greater emphasis on achieving a more well-rounded and flexible approach to work.

At Caterpillar there is a recognition of the changing needs and expectations of employees. The company acknowledges the importance of work-life balance and strives to provide support to its workforce in this area. One notable aspect is the increased flexibility in where and how work is conducted. Thanks to technological advancements, employees no longer need to be confined to the office 5 days per week/ 8 hours per day. This flexibility allows individuals to create a work environment that suits their personal needs and promotes a better work-life balance. However, I agree with Simon Sinek’s quote “we are social animals that need human interaction”.

For working parents, in particular, the business acknowledges the unique challenges they face in juggling family and work responsibilities. The company understands that being the best employee and the best parent are not mutually exclusive. Employees are encouraged to learn and grow from the experiences of being a working parent, gaining valuable insights and skills from managing different aspects of their lives.

Furthermore, there is an emphasis on avoiding the need to completely switch off from work. Instead, the focus is on finding a healthy integration of work and personal life, allowing individuals to address their commitments and priorities in a way that aligns with their needs and preferences. This drive for independence empowers employees to have the freedom to say no when necessary, ensuring that they maintain a balanced lifestyle.

The company understands that a well-rounded and fulfilled employee is more productive, engaged, and satisfied in both their personal and professional lives.

-

Perkins® 904 Series: pushing the boundaries

The new model will deliver up to 129 kW (173 hp) and 740 Nm (546 lb ft) at 1500 rpm, from a compact 3.6 litre engine.

Read more -

High‑reliability power systems: The silent guardians ensuring data centre uptime

Ensuring uninterrupted performance is non-negotiable, at the heart of that reliability sits the diesel-powered generator.

Read more -

Built to make a difference: The new 5000 Series is driving progress around the world

Providing dependable power output up to 2500 kVA for standby and 2250 kVA for prime applications.

Read more -

Powering forward: Richard Hemmings on innovation, reliability and what comes next

Powernews caught up with new VP Richard Hemmings to learn more about his new role.

Read more -

A future full of momentum for Golden Arrow Marine

Building on a legacy of over 1000 Perkins engines supplied and 62 years of hands-on experience.

Read more -

Rewriting the rules of power: The electric unit driving the next wave of innovation

The Perkins battery-electric power unit continues to attract interest among original equipment manufacturers (OEMs).

Read more -

Connectivity delivers real-time insights

Perkins’ collaboration with Trackunit, delivering real-time insights to customers, increasing productivity in the field.

Read more -

Rental equipment runs on uptime

For industrial equipment rental, excellent technical support and parts availability is a necessity.

Read more -

Powering ahead in agriculture

To mark Agritechnica's 'Celebrate Farming Day', Powernews spoke to Andy Curtis, Customer Solutions Director at Perkins.

Read more -

New marine propulsion engines

Clever configuration options fulfil the current and future requirements of the industry.

Read more

Also in this issue

-

New marine engines exhibited

A new range of auxiliary marine engines were shown at METS.

Read more -

California: the state that feeds America

Adrian Bell dives into the history of Californian agriculture.

Read more -

Seeing the unseeable

The importance of thermal fluids simulation.

Read more -

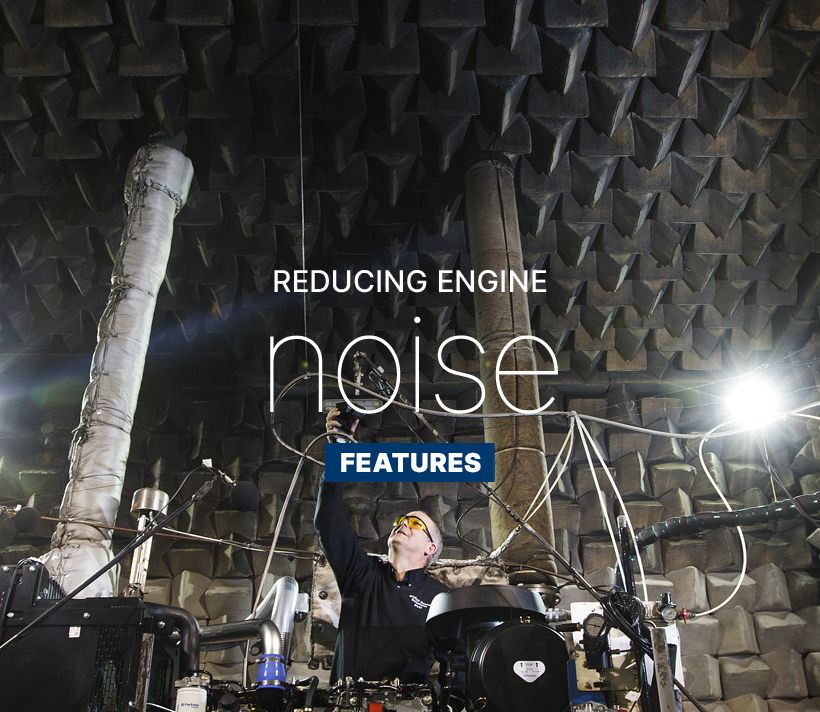

Reducing engine noise

How ‘noise chambers’ help Perkins build quieter engines.

Read more -

The Agrievolution Alliance

The global voice for agricultural equipment manufacturers.

Read more