Leaders in modular aftertreatment solutions

Perkins range of emissions technology allows you to find the right solution, every time in every market.

- Wherever in the world they’re being used, Perkins engines meet the emissions standards required

- Our engineering teams help you achieve the local emission standards without compromising high-end performance

- Through our Technology Integration Workshops, we optimise each and every engine application

- Cooled exhaust gas recirculation (EGR) is an aftertreatment solution for NOx reduction and thermal management.

- A diesel particulate filter (DPF) captures particulates formed during combustion.

- Selective catalytic reduction (SCR) is another solution for NOx reduction.

- Diesel exhaust fluid (DEF) is the key component in SCR, helping to reduce NOx levels by more than 90 percent before they exit the exhaust pipe.

- A diesel oxidation catalyst (DOC) relies on a chemical catalyst to reduce particulate matter, as part of a catalytic converter solution.

- High-pressure common-rail fuel systems achieve more efficient combustion, improving both performance and fuel efficiency. With naturally lower NOx levels, these engines require less aftertreatment.

- By installing ‘series’, or sequential turbos, we can downsize your engine to improve efficiency and reduce emissions, with no effect on engine rating.

Perkins. Engines and expertise for every need.

-

Case studies

Learn More -

Compliance needn’t be complex

Ask any of our 800+ original equipment manufacturers (OEM) customers worldwide what they enjoy most about their collaboration with Perkins and they’ll tell you about the no-fuss, meticulous approach that is our hallmark.

Learn More -

Embracing hybrid and electric opportunities

Hybrid and electric power systems are gaining traction with agricultural machine manufacturers as they develop the next generation of farm machines.

Learn More -

Emissions accomplished with Perkins

By working with Perkins, you can ensure you meet all your requirements, while keeping your engineering managers, compliance teams and accountants happy.

Learn More -

Perkins: powering more than tractors

Hundreds of thousands, even millions of farmers rely on a tractor powered by Perkins.

Learn More -

Power Solutions

We create and deliver appropriate power solutions which perfectly match the operational needs of original equipment manufacturers (OEMs).

Learn More -

Service options to suit your needs

There are many reasons why manufacturers choose Perkins to power their products.

Learn More -

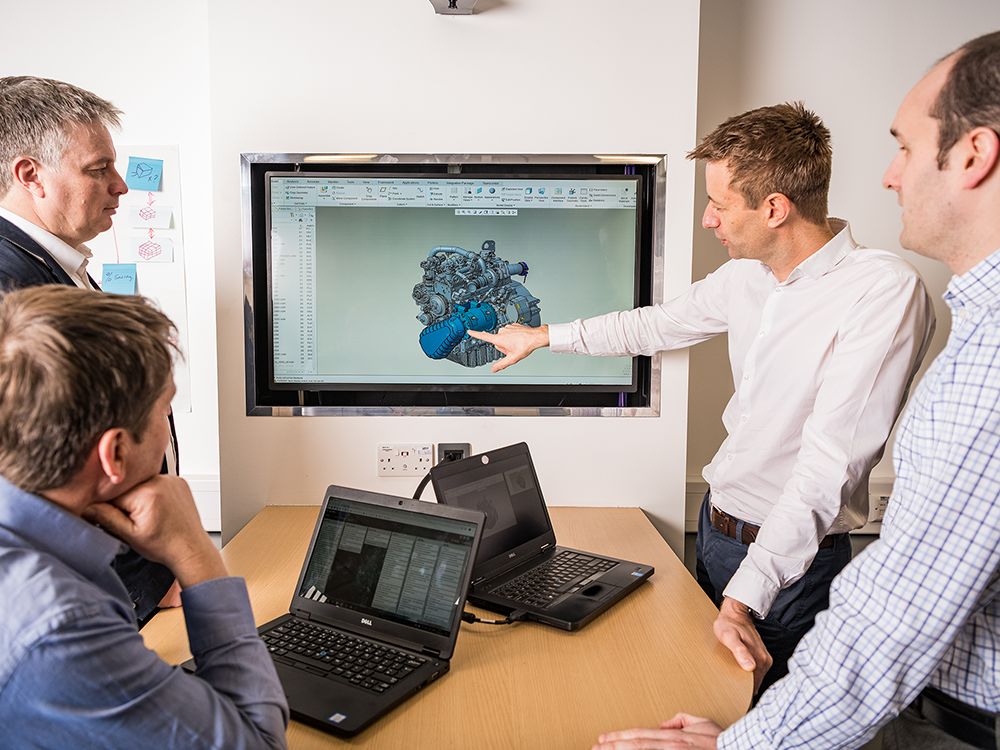

Technology Integration Workshops

Using Technology Integration Workshop to bring together the right expertise.

Learn More

-

Distributor locator

Your regional Perkins Distributor can provide local, on-the-ground engine support.

Learn More -

Powernews Q4 2025

Our digital magazine with the latest news, interviews and analysis.

Read more -

Request Consultation

If you're ready to receive trusted advice from a Perkins expert, speak to our team today.

Connect with us