Perkins launches next generation 2600 Series engine.

A key focus of the energy transition toward a lower-carbon future is the continued refinement of diesel engine designs to reduce fuel consumption, improve performance and prepare for the increased utilisation of renewable fuels.

As part of its commitment to delivering smarter solutions, Perkins has launched the Perkins® 2600 Series, a new 13-litre diesel engine platform designed to achieve best-in-class power density, torque and fuel efficiency for heavy duty off-highway applications.

Targeting applications in agriculture, construction, and numerous other sectors, the new platform extends Perkins leadership in high-performing, heavy duty engines with eight power ratings from 340 to 515 kW (456 to 690 hp) offering up to 3,200 Nm of peak torque. Industrial open power units configured with engine-mounted aftertreatment and cooling packs will also be available from the factory to reduce installation and validation costs for original equipment manufacturers (OEMs).

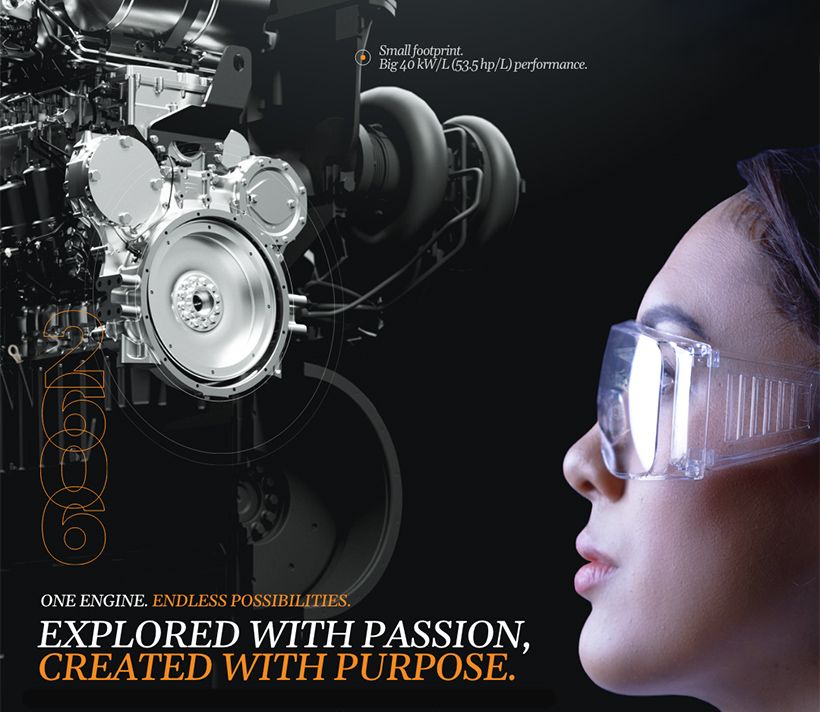

One engine, endless possibilities

Perkins will offer 2600 Series engines configured to meet the emissions standards of higher regulated countries, such as EU Stage V, U.S. EPA Tier 4 Final, China Nonroad Stage IV, Korea Stage V, and Japan 2014, as well as versions for lesser regulated countries. The engines are compatible with renewable liquid fuels such as 100% hydrotreated vegetable oils (HVO), B100 distilled Biodiesel, and up to B100 fatty acid methyl ester (FAME) standard biodiesel by working with the local Perkins distributor*. Additionally, its core architecture supports the future development of spark-ignited natural-gas and hydrogen fuel capabilities.

To date, engineers have completed more than 25,000 hours of design validation on the 13-litre engine platform. It is ideally suited for dozens of off-highway applications, such as agriculture tractors, combines, harvesters, self-propelled sprayers; wheel and track loaders, excavators, dozers and other construction machinery; heavy lift trucks and other material-handling equipment; and large industrial pumps and compressors.

“As the off-highway industry advances toward a lower-carbon future, equipment manufacturers still face expectations for long-term productivity and reliability in the world’s most demanding work environments,” says Jaz Gill, Vice President of Global Sales, Marketing, Service and Parts. “The new Perkins 2600 Series engine platform demonstrates how we’re leveraging our experience, intelligence and commitment to help OEMs navigate the energy transition with power solutions that deliver exceptional performance on the worksite.”

One and done

The dynamic 2600 Series delivers power density and performance in a uniquely compact package – providing an impressive 40 kW/L (53.5 hp/L) at 0.45 kW/kg (0.27 hp/lb). That makes it an ideal choice for a broad range of off-highway applications, from agricultural machinery like tractors and harvesters, to construction equipment such as excavators and dozers, to material handling equipment as well as industrial pumps and compressors. The 2600 Series is built and tested to power more of the equipment that moves the world forward.

A new era in engine performance

The Perkins 2600 Series showcases the company’s commitment to innovations that support the success of customers by challenging traditional assumptions, as evidenced by the 82 patents granted to date across the entire engine platform.

It is designed to perform at altitudes of up to 12,000 ft, and in extreme ambient temperatures as high as 60 C (140 F) and as low as minus 40 C (minus 40 F) with aids.

The engine supports quality, reliability, and easier maintenance through numerous design enhancements, including the integration of components as well as a reduction in the number of leak joints by more than 45%. Together, the upgrades result in more hours of dependable performance in the field. With the 2600 Series, machines will work longer with simplified service and maintenance, featuring extended oil and fuel filter change intervals of up to 1,000 hours.

The 2600 Series achieves fuel consumption as low as 185 g/kW-hr through advanced control algorithms coupled with optimised electronic architecture (OEA) to match operating cycles for various ambient and altitude conditions.

In addition, the range will offer telematics solutions enabling OEMs to collect, analyse, and integrate key engine performance data within a connected intelligent platform.

By modularising and eliminating components, its architecture is space-protected to accommodate configuration adjustments anticipated for future tiers of emission standards in the U.S. and EU without relocating customer connection points. All eight power ratings for higher regulated markets will be available on a common core engine, enabling OEMs to reduce their inventory and integration costs. The combination of the all-new rear gear train, stiffer core architecture, and common rail fuel system reduces noise by up to 3 dB when compared with Perkins current 13-, 15- and single-turbo 18-litre engines.

How will the 2600 Series benefit the OEM and end user?

- Class-leading power density, torque and productivity with 40 kW/L of power density.

- Common value streams - one single engine platform for multiple sized machines, on a single iron set, with only software re-rating required. This means consolidating engine inventory, aftermarket parts inventory, service literature, and knowledge training.

- Diesel-electric needs: The Perkins 2606 will meet constant speed needs for diesel-electric applications. Programmable PID governor tunes have been used successfully for multiple diesel-electric customers that require consistent constant speed performance using a variable speed engine.

- Advanced controls: Next generation software controls enable real-time optimisation of performance and minimise fluid consumption; achieving fuel savings as high as 29% compared to the current Perkins® 2406.

- Reliability and durability driven by proactive quality: Combining multiple components into a single fluids and fuel module removes the potential for leaks between components.

- Improved serviceability leads to a more compact package; the Perkins 2606 features hydraulic lash adjusters that remove the need for time-intensive service interval rocker adjustments. Furthermore, the crankcase ventilation system has been embedded into the valve cover, thus removing the need to service or stock those crankcase filters.

Global support

Every 2600 Series engine comes packed with power and is backed by the Perkins global distribution service and support network. Our wide-reaching distributor network, operating in over 180 countries, helps ensure you’re never far from the genuine parts and expert service you need to keep your engines running at their peak for longer.

* To preserve the performance and integrity of the engine whilst reducing the risk of downtime or failure, fuels must meet the specifications and characteristics described in official Perkins fluids guideline documents found on www.perkins.com.

Power rating and emissions |

||

Minimum power |

340 KW |

456 HP |

Maximum power |

515 KW |

690 HP |

Rate speeds |

1800-2100 RPM |

|

Emissions |

Higher regulated countries (HRC) |

|

Engine specifications |

||

Engine configuration |

In-line 6, 4-stroke-cycle diesel |

|

Bore |

130 mm |

5.1in |

Stroke |

162 mm |

6.4 in |

Displacement |

12.9 L |

787.2 in3 |

Aspiration |

Turbocharged-aftercooled (TA) |

|

Compression ration |

18.0:1 (for HRC), 16.5*:1 (for LRC) |

|

Combustion system |

Direct injection |

|

Rotation (from flywheel end) |

Anti-clockwise |

|

Watch the 2600 Series webinar

Want to learn more about the 2600 Series? Watch the recent KHL webinar where Perkins’ team of experts provided exclusive access to the all-new 13-litre engine. There’s something for everyone in this behind-the-scenes look at the built-from-the-ground-up Perkins 2600 Series.

-

Perkins® 904 Series: pushing the boundaries

The new model will deliver up to 129 kW (173 hp) and 740 Nm (546 lb ft) at 1500 rpm, from a compact 3.6 litre engine.

Read more -

High‑reliability power systems: The silent guardians ensuring data centre uptime

Ensuring uninterrupted performance is non-negotiable, at the heart of that reliability sits the diesel-powered generator.

Read more -

Built to make a difference: The new 5000 Series is driving progress around the world

Providing dependable power output up to 2500 kVA for standby and 2250 kVA for prime applications.

Read more -

Powering forward: Richard Hemmings on innovation, reliability and what comes next

Powernews caught up with new VP Richard Hemmings to learn more about his new role.

Read more -

A future full of momentum for Golden Arrow Marine

Building on a legacy of over 1000 Perkins engines supplied and 62 years of hands-on experience.

Read more -

Rewriting the rules of power: The electric unit driving the next wave of innovation

The Perkins battery-electric power unit continues to attract interest among original equipment manufacturers (OEMs).

Read more -

Connectivity delivers real-time insights

Perkins’ collaboration with Trackunit, delivering real-time insights to customers, increasing productivity in the field.

Read more -

Rental equipment runs on uptime

For industrial equipment rental, excellent technical support and parts availability is a necessity.

Read more -

Powering ahead in agriculture

To mark Agritechnica's 'Celebrate Farming Day', Powernews spoke to Andy Curtis, Customer Solutions Director at Perkins.

Read more -

New marine propulsion engines

Clever configuration options fulfil the current and future requirements of the industry.

Read more

Also in this issue

-

New marine engines

Two new auxiliary engines powering the marine sector.

Read more -

Perkins kicks off Project Coeus

Perkins kicks off Project Coeus to demonstrate leading-edge hydrogen hybrid power solutions.

Read more -

Driving sales of Perkins® 4000 Series in India

Dependable electric power generation drives sales of Perkins® 4000 Series in India.

Read more