“The most striking thing about Speedy is its real commitment to ESG,” explains Amelia (pictured below), who joined the company following a stint as head of sustainability for one of the UK’s biggest rail operating companies.

“I felt like this was a company who wanted to make ESG part of their business. Seamlessly. The support and enthusiasm for ESG is perceptible throughout the whole organisation: within the leadership, at board level, in the way everyone within the company embraces the ESG agenda.”

And while Amelia says that’s made her job easier, her goal remains in place: to entwine ESG through every aspect of the company’s day-to-day activity, with her and her team acting as the expert advisers.

“The scale and pace of innovation in the supply chain is something to behold,” she says. “We’re probably hiding our light under a bushel when it comes to adapting to net zero – batteries, solar, hydrogen. Yet there’s still more we can do; the scale of opportunity is quite significant.”

Creating the role into which she stepped 18 months ago has served to emphasise Speedy’s focus on the importance of sustainability in the construction industry, and emphasised its potential amongst shareholders, investors and customers.

“This is about generating a measure of success of this business, for the future,” she stresses. “The messages we’re sending to the corporate world are that if you’re going to be successful, you have to embrace ESG.”

But this isn’t about jumping on the bandwagon. “Speedy published its first ‘sustainability plan’ back in 2010, and was the first company in its sector to sign-up to science-based targets to align itself with new net zero corporate standards.

“We’re already on track to deliver reductions of 50 percent in our Scope 1 and 2 emissions by 2030. Modelling on Scope 3 is being finalised, and we’ll deliver net zero across the entire business by 2040.

“We’re going to decarbonise by 90 percent – that’s deep decarbonisation. And we’re offsetting the residual 10 percent that we won’t be able to decarbonise.”

Among the technologies being pursued by Speedy are alternative power sources, including electric, and new sustainable fuels that will take carbon out of the equation. Speedy’s property estate isn’t immune, either: its Milton Keynes headquarters sport a proud Grade A rating Energy Performance Certificate for energy sourcing and efficiency, embedding technologies that include smart heating and cooling systems and LED lighting, all fully powered via solar photovoltaic arrays.

Speedy’s ESG focus isn’t just about internal progress. Net zero demands are making their way up the supply chain. “There’s palpable demand from customers. They’re being asked by their clients to deliver net zero, so they’re looking for zero-emission equipment.”

That’s prompted a two-pronged approach: Speedy invests in net zero technologies across it’s supplier base, including an exclusive low-carbon partnership with tool manufacturer Milwaukee, while also embracing and encouraging the circular economy through a comprehensive retrofitting programme.

“Prime examples are the hybridisation of our diesel lighting fleet, and a retrofitting programme to move our generators from Stage III to Stage V emissions standards.”

While that may satisfy Speedy’s own decarbonisation commitments, it’s not enough to placate all customers. Amelia points to research from the investment company Blackrock that suggests the most common barrier cited by companies to net zero engagement is the availability of data.

“These companies need accurate carbon data to inform their decision-making,” she explains. “We’ve appointed Hydrock, an engineering and sustainability consultancy, as our sustainability partner to help us on that carbon data journey.

“They’re going to help us manage our carbon data – measuring and reporting on emissions, waste streams and resource consumption – so that we can support our customers with Net Zero hiring decisions.”

But it’s Speedy’s own supply chain where Amelia has her sights set next. “We need to work together with our suppliers to mobilise them to net zero too, so that they can help us with our own demands for product and service innovation.

“Original equipment manufacturers (OEMs) are critical in helping us achieve that goal, because 90 percent of our emissions are in the supply chain. Collaboration is key. We don’t want a kaleidoscope of different initiatives.”

Here, Speedy is working with another consultancy – Larch – to help ‘heatmap’ suppliers, in a bid to identify risks and opportunities. “We need them to come with us, to help us figure out what innovations we need to deliver, and how they can help us with that.

“Some won’t have been built yet, but if we work with them as partners then we can figure out the when, why and how much, too.”

It’s not just the construction industry where Speedy is responding to customer demand for net zero. As the UK’s leading rental provider, the company has developed a home improvement strategy where it hopes to inspire a ‘Hire Revolution’.

“This is another manifestation of the circular economy,” Amelia enthuses. “We’re trying to make hire the first choice in a sustainable, circular economy. The idea is that we want to persuade DIYers to making more sustainable choices. Why buy equipment – which might then languish in a shed or garage after it’s been used only a couple of times – when you can hire it instead?”

Whether it’s up or down the supply chain, it’s discussions with OEMs or customers that drives Speedy to these solutions.

“Take our relationship with Perkins,” Amelia suggests as an example. “The internal combustion engine (ICE) is still in existence. So we need solutions that can move us from an ICE using fossil fuels to one that doesn’t.

“Take generators. These are one of our top products, so we have to find a diesel fuel alternative. That’s why we’ve focused on the lighting towers. It’s an easy way to begin the transition, to start our journey of moving fossil fuels out of the business.

“Suppliers like Perkins understand our technology, we can work closely with their innovation teams, and we can together come up with new solutions. When we work with Perkins, it’s like pushing at an open door. They’re a responsible supplier in the supply chain, despite not being a direct supplier. Collaboration is the way forward.”

While zero emissions and environmental concerns are one of the major drivers to any ESG strategy, it’s important to remember the other elements too, emphasises Amelia. “Climate solutions are but one pillar, but they do help us accelerate innovation: not only can we develop new ideas to meet environmental objectives, but we can create better products and services as well.

“Then there’s the social component: we’re building a culture where everyone belongs, through initiatives such as the Speedy Family and Speedy Spirit, and finessing a company culture that’s a progressive, friendly and supportive working environment.

“What can we do to include everyone? How do we deal with under-represented, or ‘forgotten’ groups: ex-offenders, who might struggle to find employment; bringing young people into the industry, giving them career line of sight and development plans; helping military veterans make the transition to civilian life? And mental health: it’s the number one issue in construction.

“Finally, what about support for the communities in which we work? We’re a national organisation with more than 200 locations – what can we give back?”

With ESG now threaded through every strand of the business, Amelia says it’s at an exciting phase. “Even more so, given we have a new chief executive – Dan Evans – who’s just stepped into the role. Dan’s been in the business for a number of years, in a variety of roles, and his commitment to ESG reflects the business itself: ESG is no longer an add-on, but an essential element for business growth.

“It’s where the demand is.”

Perkins’ collaboration with Trackunit, delivering real-time insights to customers, increasing productivity in the field.

Read moreFor industrial equipment rental, excellent technical support and parts availability is a necessity.

Read moreTo mark Agritechnica's 'Celebrate Farming Day', Powernews spoke to Andy Curtis, Customer Solutions Director at Perkins.

Read moreClever configuration options fulfil the current and future requirements of the industry.

Read moreWho keeps the lights on when the grid can’t? The power generation sector, of course. In the UK, its interests are represented by The Association of Manufacturers and suppliers of Power generating Systems (AMPS) – whose new director general, Alan Beech, came into post earlier this year.

Learn MoreHave you ever looked at the name of a Perkins engine and wondered what all those numbers and letters actually mean? If so, you’re certainly not alone. But rest assured the nomenclature is anything but random.

Read moreOne alternative fuel option we’ve researched heavily and have accommodated in our diesel engines for more than a decade is hydrotreated vegetable oil (HVO) – which must meet the EN 5940 standard – with the Perkins® 400 to 5000 Series able to use up to 100% HVO.

Read moreIn part two of our spotlight on marine we talk with Ben Lewis commercial manager, Dave Wood, application and tech support team lead and Stuart Phillipson, marine application and tech support to find out more about what’s in development for the marine range.

Read moreWhy stick to one fuel, when you can have a configurable power system?

Read moreMore than just a curiosity, they offer us different routes to future food security.

Read moreConstantly innovating to meet the changing electric power marketplace.

Read moreManufacturing industrial engines at our Curitiba facility since 2003.

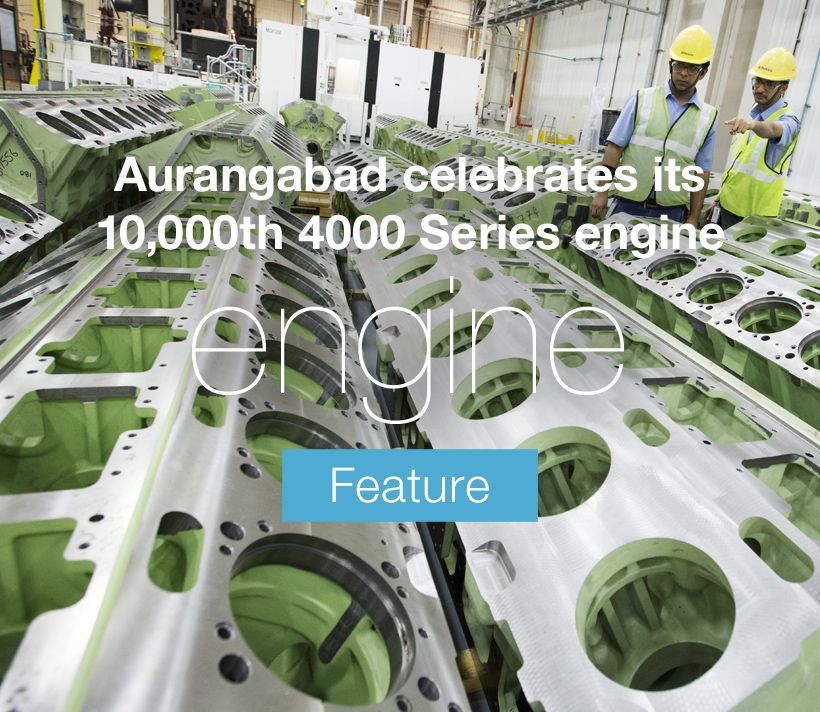

Read morePerkins Aurangabad celebrates the production of its 10,000th 4000 Series engine.

Read more