Taylor Power Systems generates more than energy with their line of life-saving products

When tornados decimate towns. When heatwaves cause brownouts. When earthquakes rupture power lines. When we find ourselves in times of true crisis, we look to power. Literally. Taylor Power Systems creates prime and standby power generation resources that keep critical systems running and help save the lives of people when they’re most vulnerable. The generators they design and manufacture keep the power on across the country for everything from municipalities to nursing homes to oil and gas companies to commercial farms and hospitals.

Based in Clinton, Mississippi, the Taylor Power team builds their products as if lives depended on them, because they actually do. “I can’t think of a single team member here that doesn’t appreciate the gravity of what we’re doing, from the design stage to the R&D team that’s making sure that we have a quality product to the people that assemble them and even the testers on the way out the door,” said Thomas Culpepper, Manager of product design and development. Taylor’s generators are there to keep life as we know it running when the worst is upon us. “I took great pride as a generator technician in knowing that most often I was running towards the storm in the face of people running away from it,” Thomas recalled.

Powered through innovation

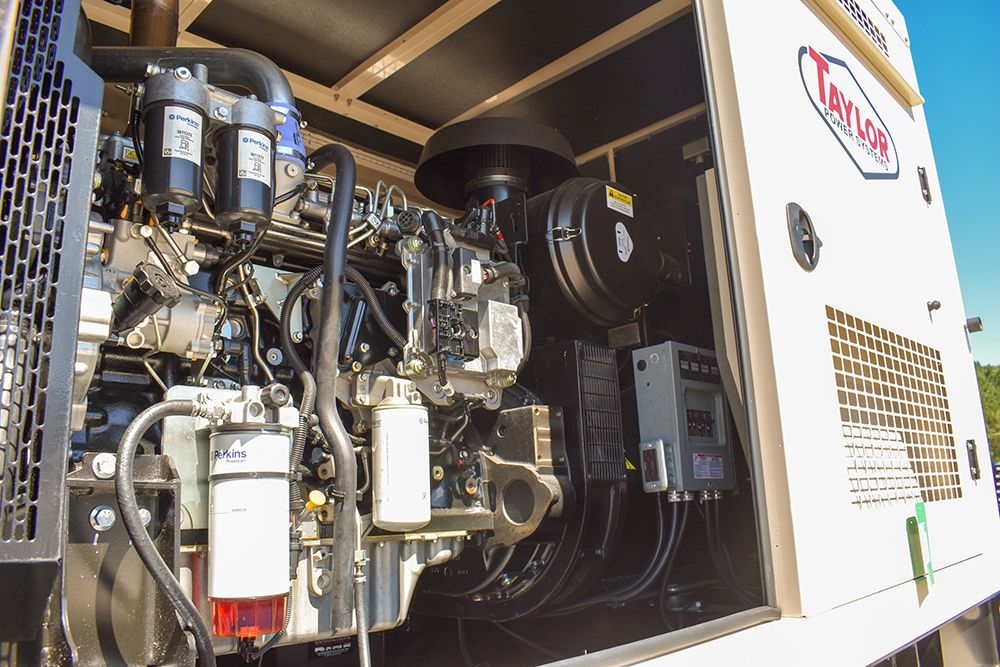

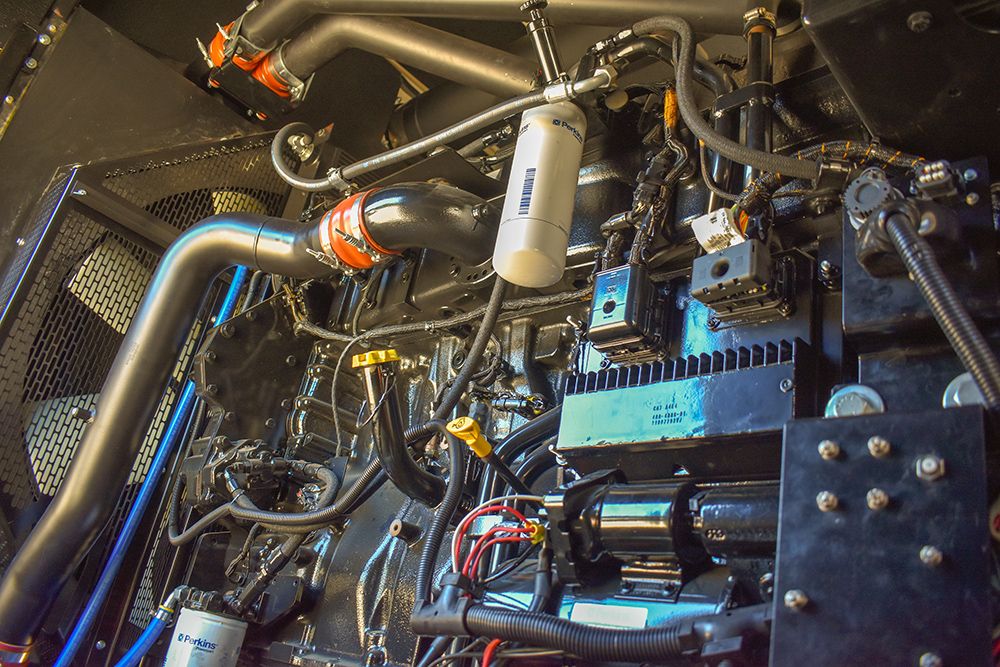

Since the company’s founding in 1986, Taylor Power has partnered with Perkins to ensure that their generators are completely dependable on both the best and worst days imaginable. The designers and engineers at Taylor Power also know they can go directly to the Perkins team to help conquer the proverbial outside-the-box challenges—like when leading fruit and produce companies asked Taylor Power if they could bring a semi-vintage model of intermodal generator back to market because it had an unparalleled history of reliability. In determining exactly how to customise the product to meet the client’s specific application, the Taylor Power team worked alongside the Perkins team, resulting in the T15U generator, with a U.S. EPA Tier 4 Final 404F engine capable of 24 horsepower with a practically unheard-of service interval of 3,000 hours.

The Taylor Power crew also didn’t hesitate to invite Perkins factory engineers to the table when they decided they needed to craft a 750-kilowatt standby-power generator to address a massive gap in their offerings. To help bring the Taylor designers’ vision to life, Perkins expanded the capabilities of the 18L, Perkins® 2806, with increased power density, to now support up to 750kWe output, while also improving the air filtration system to allow service from either side. This brand new TD750 generator also has a smaller footprint and is competitive on price. Final reviews are still being done on the new addition to the Taylor Power family, but once it’s officially market-ready, it’ll be capable of powering large office complexes, data centres, hotels, municipalities and medical facilities. “We’re really excited about this,” Thomas said. “The sales department’s energised, and we have people on the shop floor that don’t normally work in R&D that are asking to work on this project. There’s a lot of buzz in the building about it.”

Agriculture is another significant market for Taylor Power, which means there are a whole lot of poultry farms across the country that have generators equipped with Perkins engines. And a typical chicken farm holds between 36,000-50,000 birds, so if the power fails in the summer and the Taylor Power generator didn’t kick in, the loss could be catastrophic. “The generators in the agriculture market are protecting the livelihood of farmers,” Thomas pointed out. “In some instances, poultry farmers don’t want anything else. They insist on a Perkins engine.”

Taylor Power is indeed powering our lives day after day. One might even say they’re as integral to America as the Statue of Liberty—which just happens to have a Perkins powered Taylor Power generator on its grounds at Ellis Island.