As part of today’s evolving energy landscape, original equipment manufacturers (OEMs) producing equipment for industries ranging from power generation to heavy machinery must keep up with customers’ ever-changing needs. This includes being prepared to support a range of future power solutions and alternative fuel options that offer a lower carbon footprint, especially when considering the entire lifecycle of the fuel source.

At Perkins, we are committed to supporting OEMs through the evolving energy landscape, and we help customers determine suitable options by dedicating time and resources to thoroughly researching a variety of alternative fuel options for our engines. One alternative fuel option we’ve researched heavily and have accommodated in our diesel engines for more than a decade is hydrotreated vegetable oil (HVO).

In this paper, we dive into all the details on what HVO is and how HVO compares to both biodiesel and ultra-low sulphur diesel (ULSD). We also highlight the results of the extensive testing we’ve performed in cooperation with one generator set OEM running HVO in a Perkins engine and the benefits OEMs, and their customers, can experience when making this swap.

First commercialised as an alternative fuel option in 2007, HVO is a renewable drop-in alternative to diesel. Common feedstocks for HVO include waste cooking oils and virgin plant oils such as soy, rapeseed, and palm. Produced through a process called hydrotreating, oxygen and other impurities are removed from the feedstock, resulting in a high-quality paraffinic hydrocarbon chemically similar to traditional diesel.

Since the hydrocarbon structure of HVO and diesel are similar, the two fuels exhibit comparable combustion behaviour, performance, and fuel efficiency when used in a diesel engine. Due to these similarities, HVO is sometimes referred to as renewable diesel and can be used as a drop-in replacement fuel, meaning no modifications are required to an existing diesel engine to use HVO.

Since the hydrocarbon structure of HVO and diesel are similar, the two fuels exhibit comparable combustion behaviour, performance, and fuel efficiency when used in a diesel engine.

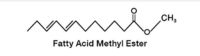

HVO and biodiesel are both renewable, plant- or waste-derived alternatives to diesel, yet these two fuels are quite different. One of the key differences is the production methods used; biodiesel is made from vegetable oils, animal fats, or used cooking oils using a process called transesterification, which converts the oils into Fatty Acid Methyl Esters (FAME), while HVO is produced using hydrotreating as described above.

As a result of these different production methods, HVO is a pure hydrocarbon fuel that closely resembles diesel while FAME biodiesels can contain 10 – 12 percent oxygen, leading to higher oxidative instability. Additionally, biodiesel is prone to gelling at low temperatures (-5°C to ~15°C depending on the feedstock used). Together, these two characteristics mean that FAME biodiesels cannot be considered a drop-in fuel since the engine may be incompatible or need modifications to run the biodiesel, or a change in maintenance procedures may be required. Additionally, FAME biodiesels generally have a shorter shelf life than HVO due to their higher susceptibility to oxidation.

| Biodiesel (FAME) | Hydrotreated Vegetable Oil (HVO) (Renewable Diesel) | |

| Source | Vegetable oils and fats | Vegetable oils and fats |

| Process | Transesterification | Hydrotreating |

| Chemistry |  |

|

| Product | Oxygenated, ester | Non-oxygenated, paraffin |

| Replacement for diesel? | Yes, with some cautions | Yes |

| Specifications | ASTM D6751, EN14214 | EN15940 |

Table 1. A comparison of the properties of FAME biodiesel and HVO

Diesel is often blended with FAME biodiesel, which offers benefits such as reducing lifecycle CO2 emissions, improving lubricity to reduce engine wear, and lowering particulate emissions versus using unblended diesel. While up to a 20 percent blend of biodiesel fuel by volume (B20) is acceptable for use in many Perkins’ engines, using a blend above B20 can lead to bacterial growth that impacts maintenance of the fuel system. HVO does not have this same consideration and can be used in a pure state or at any EN590 diesel blend level

Since HVO is a pure hydrocarbon, it is backwards compatible with older engines and can be used in most engines manufactured since the early 1990s. However, since diesel engines built after 2007 are required to run ultra-low-sulphur diesel (ULSD), we will focus our comparison of the characteristics of HVO to ULSD.

One of the key differences between HVO and ULSD is the feedstock source. As mentioned, the source of HVO is organic vegetation either as a virgin or secondary source. Either way, this is a renewable and sustainable feedstock. Since ULSD is a fossil fuel, the feedstock is crude oil. As a result of these different feedstocks, HVO contains virtually no sulphur, resulting in almost zero SO2 emissions during combustion. Even though ULSD has a sulphur content of 15 ppm or less, which is significantly lower than traditional diesel that could have been up to 500 ppm, there are still SO2 emissions occurring when using ULSD.

Due to the consistency and chemical stability of HVO, it is resistant to a variety of factors such as oxidation and microbial growth, making it suitable for long-term storage without degradation. Since ULSD can oxidise and is more prone to moisture absorption that can cause microbial growth, it must be carefully managed when stored and has a much shorter shelf life, especially when the ULSD has a high FAME content (B20+).

Using HVO can significantly lower life cycle emissions from well-to-wheel for multiple reasons. First, HVO can be produced locally from available feedstocks, leading to a reduction in the emissions associated with the transportation of raw materials and the fuel itself.

Second, the feedstocks for HVO are derived from biological sources that absorbed CO2 as they were grown. Therefore, when HVO is burned as a fuel and CO2 is released back into the atmosphere, the majority of these emissions can be accounted for with the CO2 absorbed during the feedstock’s growth, resulting in a closed carbon loop. Or, if the feedstock comes from organic waste materials, less materials are potentially transported to landfills.

When HVO is burned as a fuel and the CO2 is released back into the atmosphere, the majority of these emissions can be accounted for with the CO2 absorbed during the feedstock's growth, resulting in a closed carbon loop

Since HVO has a higher heating value per unit of mass, it contains more energy for combustion than ULSD on a mass basis. This means that each gram of HVO can produce more energy than the same mass of diesel, making HVO a highly energy-efficient fuel option, even if the engine consumes slightly more HVO by volume. This is because the high energy content of HVO compensates for the lower density, helping maintain comparable performance to ULSD.

One of the biggest challenges with the adoption of HVO today is the cost and availability of HVO compared to ULSD. HVO tends to be more expensive and has limited availability in some regions. However, this is quickly changing as the sale of HVO is becoming more common in Europe and North America through fuel distributors, online fuel suppliers, and some fuel stations. With a well-established infrastructure for fossil fuel production and distribution, ULSD is widely available globally. While costs are generally lower than HVO, diesel is highly sensitive to price fluctuations due to constantly changing crude oil prices.

Lubricity, which is the ability of a fuel to minimise wear between moving metal parts in a fuel injection system, is a key concern from a fuel component perspective. Since HVO is highly refined and almost entirely paraffinic, it’s lubricity is not as good as the lubricity of a standard diesel. However, HVO fuels that meet the EN15940 standard are required to have lubricity additives, which means this is not an issue for EN15940 HVO fuels.

Recently, our engineers worked on a project in cooperation with Jubaili Bros, an OEM using Perkins engines in their diesel generator sets, to research the impacts on performance and emissions when using HVO for a generator set application running a Perkins® 1103 Series engine. The testing was completed at Perkins Engines Company Ltd, Peterborough UK between January and July 2024. The goals of this project were to:

Test Setup

At a high level, our testing involved running a 1,000-hour high-load generator set durability cycle test while executing target performance tests every 250 hours as the engine was aging (Figure 1). Figure 1

Figure 1. The high-load durability cycle test setup.

The periodic performance tests we ran at 0, 250, 500, 750, and 1,000 hours included load acceptance, fuel consumption, and emissions testing. For the load acceptance test, we tested to ISO 8528 standards against G2 test cycle, which specifically defines performance standards for generator sets, using automated test scripts through a load bank with a pass or fail result (Figures 2 and 3).

Figure 2. The setup for the load acceptance testing.

Figure 3. An example of a typical load bank diagram we used.

For the fuel consumption testing, we ran the engine at steady-state load conditions for 30 minutes after conditioning, with testing starting at the highest load and working down the load to maintain consistent engine temperatures where possible. An auxiliary 20 litre fuel tank was weighed before and after running each load point, to 1 gram resolution with a maximum error of 3 grams; corresponding to a maximum 0.2 to 1% error based on fuel consumption over these tests (Figure 4).

Figure 4. The fuel consumption testing setup.

For the emissions testing, we used a portable emissions measurement system (PEMs) to measure tail pipe emissions including CO2, CO, hydrocarbons (HC), and NOx (Figure 5). We also performed soot particle measurements using an AVL 483 micro soot sensor and measured exhaust mass flow.

Figure 5. The emissions testing setup

At the end of the 1,000-hour load test, we then performed the target performance tests using HVO from three additional suppliers to determine if the source of the HVO would have any significant impact. Some additional notes on the HVO we used:

| Parameter | EN590 | HVO 1 | HVO 2 | HVO 3 | HVO 4 |

| Density0 | 0.8345g/cm3 | 0.7849g/cm3 | 0.7849g/cm3 | 0.7808g/cm3 | 0.7811g/cm3 |

| Cetane Index1 | 51.7 | 90.1 | 89.5 | 87.8 | 84.4 |

| Water Content2 | 20ppm (20ppm) | 16ppm (11.3ppm) |

20ppm (16ppm) |

12ppm (9ppm) |

39ppm (10.4ppm) |

| Lubricity WSD3 | 414µm | 329µm - 450µm* | 420µm | 420µm | 440µm |

º Averages of all samples – 2 different methods have been used to test density giving a possible 1 percent variation.

¹ Using 4-square method ASTM D4737-21.

² Using ASTM D6304 - Max value seen (Average).

³ Mean Wear Scar Diameter – ISO12156 against 320µm Repeatability = 69.53 Reproducibility = 97.342.

* Values from start and end of HVO IBC - 1 (lower number being at the end of the IBC).

Table 2. A comparison of the characteristics of the EN590 and the HVO sourced from four different UK suppliers for this testing.

Beyond these tests, we also performed noise and vibration testing to see if there were any differences in the noise or vibration levels when running HVO in the engine. We performed a comparison of EN590 and HVO at 0 hour and then reran the testing with HVO at 1,000 hours. The main goal of this testing was to determine if a user might think something was wrong with the engine if the noise and vibration levels were significantly different when running HVO versus EN590.

Overall, this testing supported our hypothesis that HVO could be used as 1-1 drop-in replacement for EN590 diesel in the generator set with no specific engine conversion process needed when HVO is used for the first time or thereafter. The tanks and filters also do not need to be cleaned when switching between HVO and diesel. Other high-level results of the testing included:

Digging down into our results, regarding fuel consumption, our testing showed that HVO EN15940 fuel consumption averaged about 2 to 2.5 percent (max 3.7 percent) higher than EN590 by volume (Figure 6). This difference is likely explained by the fact that EN590 has ~6 percent higher volumetric density, which is partially offset by its lower energy density compared to HVO EN15940. These results were in line with our expectations and remained consistent throughout testing.

This testing supported our hypothesis that HVO could be used as 1-1 drop-in replacement for EN590 diesel in the generator set with no specific engine conversion process needed.

Figure 6. A comparison of fuel consumption for EN950 vs. HVO EN15940 as the load applied changed.

Additionally, our emissions testing revealed that when running HVO, there were similar tail pipe emissions for CO, CO2, NOx, and soot levels, but a noticeable reduction in tailpipe HCs as shown in Figure 7. We believe this reduction in tailpipe HCs was due to the increased paraffinic, and reduced aromatic, proportion of HVO compared to diesel. This lowers the fuel’s final boiling point, which promotes earlier, and more complete, combustion that reduces the partially combusted HCs seen in the exhaust gas. This correlates with the increased cetane number of the HVO.

Figure 7. Emissions data comparing EN590 to HVO. Note: g/kwh values were normalised against generator set output power taken from the control panel and from the 25% load EN590 emissions measurement.

Through our high-load endurance testing, we saw that during the first 500 hours of running, the engine speed at the 110 percent load point gradually decreased over time (Figure 8) which can occur as a new engine is run-in. Before running the second 500 hours of testing, we completed a ‘high-idle adjustment,’ which brought the frequency/engine speed back up to the higher 50.8 Hz/1,525 RPMs for the start point of the second part. This was successful and we saw only a slight speed reduction during the second 500 hours of testing as shown in Figure 8.

Figure 8. A plot of our 1,000-hour high-load generator set durability cycle test.

Regarding the service life of the engine when running HVO, we found that engine performance remained acceptable through the 1,000-hour test period. Oil condition remained acceptable, service intervals were unchanged, and based on a visual assessment, the engine condition looked as expected as well (Figure 9).

Figure 9. The engine after running on HVO for 1,000 hours.

Additionally, the noise and vibration testing revealed the following results, as shown in Figure 10:

Figure 10. A comparison of all three noise and vibration tests.

For the final part of our testing, we aimed to determine if the source of the HVO could have any significant impact on performance, emissions, and efficiency. No significant differences in performance, emissions, or fuel consumption was found between the variants. Fuel consumption for each variant was consistent, with approximately 1.5 percent variation at 100 percent load (Figure 11).

Figure 11. Fuel consumption of the different HVO variants at 0 percent, 50 percent, and 100 percent loads.

Across all variants, no significant changes were observed except for an increase of soot noted when testing HVO 2 (Figure 12). We repeated this test to eliminate the possibility of a measurement error and came up with the same result. In general, this test demonstrated that using EN15940 fuels from different sources offers a level of stability and equality.

Figure 12. A comparison of emissions testing for the four HVO variants used. Note: g/kwh values were normalised against generator set output power taken from the control panel and from the 25% load HVO1 emissions measurement.

While running a generator set on HVO provides similar performance to diesel, there are several ancillary benefits OEMs, and their customers, can experience by making the switch. First, substituting HVO for petroleum-based diesel reduces life cycle greenhouse gas emissions, while maintaining similar tailpipe greenhouse gases emissions as traditional diesel.

Additionally, having the ability to highlight that your equipment’s engines can run HVO can be a competitive advantage as you may have the opportunity to differentiate your company and win more business. Plus, having the confidence to know you can switch your engine to HVO, or any HVO/diesel blend, also provides greater flexibility in fuel sources as well as supply chain resilience. Having an alternative fuel option to switch to when needed can reduce the risks associated with price volatility and supply chain disruptions that can happen with fossil fuels.

As an OEM serving the power generation or heavy machinery industries, you likely have customers looking to implement more sustainable or flexible power solutions while maintaining performance and fuel efficiency. As demonstrated by our rigorous testing, this can be achieved by using HVO as a drop-in alternative to traditional diesel in a Perkins engine. The compatibility of HVO with existing infrastructure offers OEMs and their customers the opportunity to focus on today’s evolving energy landscape related while increasing operational flexibility and supply chain resiliency.

Learn more about our range of advanced power solutions.

All information in this document is substantially correct at time of printing and may be altered subsequently.

Produced in England ©Perkins Engines Company Limited 2025.. Perkins Non-Confidential

Perkins is continuously following the development of renewable and lower-carbon intensity fuels.

Learn moreThe technology we use ensures our products meet the standards wherever the engines are being used in the world.

Learn MoreCollaborating with customers to deliver innovative solutions and achieve sustainability goals through the energy transition.

Learn morePlease fill out the form below and your local distributor will be in touch soon to arrange for a quote or a personal consultation.

false