Rent or buy - how to decide and why it matters

Anyone who needs a specialised tool or piece of equipment for a particular job is much more likely to rent it than buy it. After all, it makes no sense to pay the full purchase price for something that will sit idle most of the time. The logic is as compelling for a homeowner with a weekend project as it is for a contractor with a huge construction site, but that’s where the similarity ends.

The homeowner probably doesn’t have a project scheduled every weekend, but a successful contractor almost certainly has one or more construction sites in operation every day. That profoundly changes the dynamic of the contractor’s rent/buy decision by introducing a range of economic issues the homeowner never has to consider. It is those issues that fuel the steady growth of the equipment rental industry worldwide.

Why equipment rental makes sense...

Why would a contractor rent a piece of equipment that is used often, or even daily?

There are three basic reasons in favour of rental

The most obvious one is that renting eliminates the need to expend the capital required to purchase the equipment outright or the credit needed to finance it. Those resources can then be allocated to other productive purposes. Also, unlike a capital equipment debt, the rented equipment probably does not show up as a liability on the company balance sheet.

But the cost of ownership extends well beyond the initial purchase. Owned equipment has to be maintained and that means either skilled personnel on the payroll or bills from an outside supplier.

Compliance with evolving environmental and legal requirements is another potentially costly issue that can be avoided with rental equipment. The rental house owns the equipment and compliance is their responsibility.

If the maintenance is done in-house it requires an expenditure for any specialised tools that may be needed along with a spare parts inventory, a stock of fluids and other materials, a place to perform the services and probably one or more vehicles to handle maintenance or repairs on the construction site. For rented equipment, all of those expenses are the responsibility of the rental house.

Rented machines are returned to the rental house when they’re no longer needed. That frees the contractor from the task of selling equipment that is no longer needed on the used market which requires experience, time, research and personnel if it is to be done effectively.

And rented equipment is delivered to the construction site by the rental house. That means the contractor doesn’t have to purchase and maintain a fleet of trucks and trailers to move it from site to site. And if the rented machine breaks down on the construction site, the rental house can usually supply a replacement on very short notice.

... and when it doesn’t.

Even with all of those advantages, equipment rental isn’t always the best option for a contractor; rental also has its down sides. As a rule of thumb, it probably makes sense to buy a piece of equipment that will be used on projects 60 to 70 percent of the time. Even here, however, a rental is an excellent way to ‘try before you buy’ and evaluate different machines from different manufacturers or different models of the same machine.

There are there basic reason in favour of ownership

Rental equipment is not always instantly available. Rental houses deal with multiple customers, many of whom are likely to be competitors with similar projects. Even commonly used machines may be unavailable from time to time and specialised equipment is rarely stocked in quantity and tends to disappear quickly.

Purchased equipment may be preferentially allocated to high value or time sensitive projects at the owner’s discretion or quickly switched between construction sites as needed. It’s also available 24/7/365 to meet emergency needs or handle jobs of opportunity on short notice.

In certain cases purchasing may allow the contractor to take advantage of special low interest financing offered by OEMs and dealers which can be more cost effective than a rental. Making the correct decision requires a careful analysis of the comparative costs over the lifecycle of the equipment and clear recognition of the fact that the machine begins to lose resale value the instant it is put into service.

Purchasing equipment gives the contractor access to the used market and the potential for substantial cost savings. Paradoxically, used rental equipment is often available for sale at very attractive prices with a reasonable expectation that it has been well maintained. Because rental fleets are constantly upgraded such machines often have been in service for only a year or two.

A closing thought

Whether the best choice for a particular contractor’s situation is a purchase or a rental the machine must deliver the performance and reliability expected and that depends largely on the engine chosen to power it. Perkins is a key supplier to the rental industry thanks to a variety of reasons including proven engine performance under demanding conditions, the Perkins Rental Support Programme and the global network of distributors and dealers.

Got something to say?

Share this story and get involved in the conversation on social media #Powernews

Related articles

-

Powering forward: Richard Hemmings on innovation, reliability and what comes next

Powernews caught up with new VP Richard Hemmings to learn more about his new role.

Read more -

Rewriting the rules of power: The electric unit driving the next wave of innovation

The Perkins battery-electric power unit continues to attract interest among original equipment manufacturers (OEMs).

Read more -

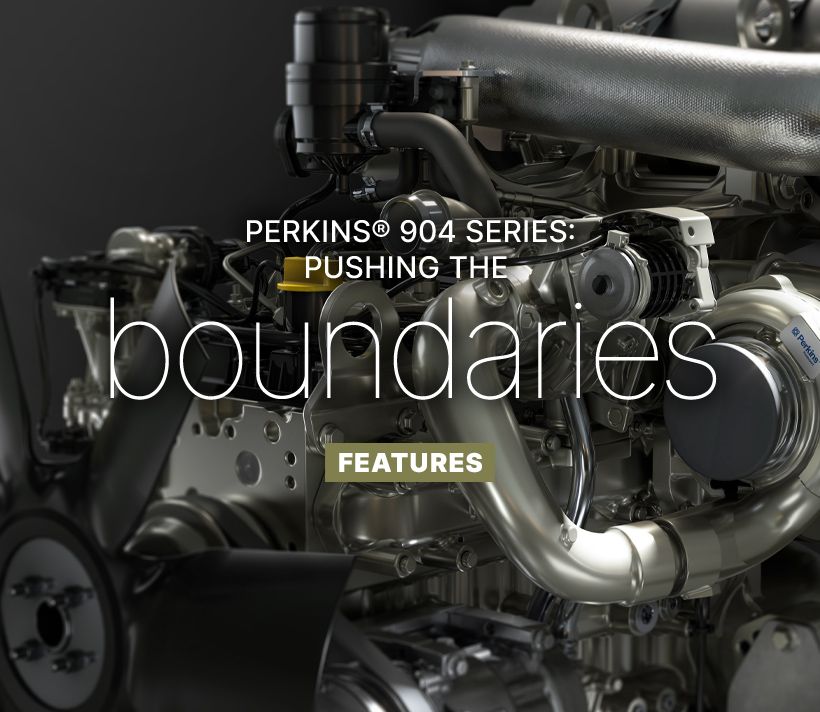

Perkins® 904 Series: pushing the boundaries

The new model will deliver up to 129 kW (173 hp) and 740 Nm (546 lb ft) at 1500 rpm, from a compact 3.6 litre engine.

Read more -

Built to make a difference: The new 5000 Series is driving progress around the world

Providing dependable power output up to 2500 kVA for standby and 2250 kVA for prime applications.

Read more