Light on-demand

Just because it’s dark doesn’t mean life stops or outdoor work has to come to a halt. Light towers are a must-have for night-time work for applications ranging from remote oil/gas rigs and construction sites to concert venues and special-event parking lots. And these days, where “off-hours” are practically non-existent, a continuous, reliable light tower with on-demand illumination and minimum maintenance downtime is crucial.

Consistent power for on-going projects

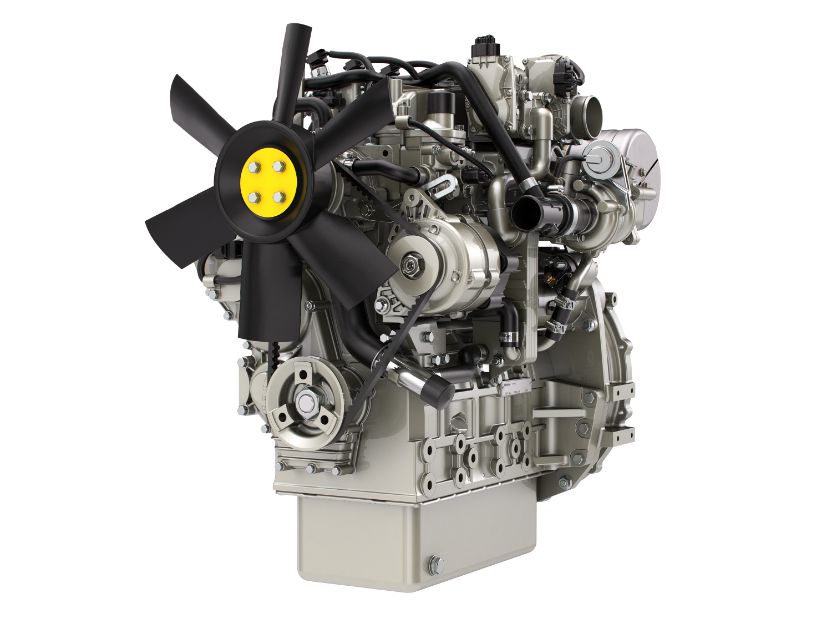

“We knew Perkins as a recognised global supplier with service and support capabilities just about everywhere,” said Dave Jones, Vice President of sales. “And we recognised the value this added to our products. But even more important was the 1,000-hour maintenance interval offered by the 403F-11. This was a critical factor in our selection of Perkins. For a light tower, the fewer touch points and the fewer requirements to service the engine, the better.”

Light towers are typically run for extended periods, so the whopping 1,000-hour maintenance interval on the Perkins-powered Allmand series will lead to fewer service disruptions during ongoing projects. And not being suddenly plunged into darkness is always a good thing – right alongside decreased downtime and a healthier bottom line for the project.

Dave is quick to note one other major benefit of choosing the 403F-11 to power the Night-Lite™ Pro Series light tower lines: “One of the significant values our lights offer contractors is their resale value; it’s industry-leading, and it has been a real competitive advantage for us.” So it’s the light that truly keeps on shining.

The four SHO-HD lamp fixtures in the Night-Lite™ Pro Series light towers provide an 135,500 lumens per lamp. The towers’ Perkins engines also support up to 50 hours of continuous operation. A wide range of available options includes an eco-friendly fluid containment package to prevent spills and two different arctic packages (complete with heavy-duty battery, block heater, arctic hydraulic fluid, heated fuel/water separator and radiator cover). Not to mention an automatic light-sensing on/off system, air intake and low-fuel shut-offs and Allmand’s Balloon Light AirStar Flex diffused lighting system.

A sequenced light system provides operators with an extra layer of control on both the lights and the engine shutdown process. The tower’s Perkins® 403F-11 engine is also designed to minimise operating noise levels, with particular attention to subjective harshness to minimise perceived sound quality. It’s approved for operation on biodiesel concentrations up to 20 percent and is covered by a standard two-year warranty. And along with that warranty comes access to the comprehensive Perkins distributor network, which means that service and support is always just a few clicks away – which is yet another bright spot.

Contact Allmand for details

These energy-efficient, best-in-class workhorses tackle applications such as drill and blast, shallow depth drilling, geotechnical exploration drilling, abrasive blasting, pipeline pigging, drying and purging. Aligning pressure or flow per application not only increases versatility but also overall performance.