Pioneering innovative design in engineering since the late 1800s, UK based Bomford Turner has always been a leader in its field. Based in Worcestershire, UK, the Bomford team are rightly very proud of the quality state-of-the-art machinery they offer their loyal customers including contractors, farmers and local authority workers.

Over the years Bomford has enjoyed increasing success and impressive business growth which it attributes to several factors including a range of innovative products, to having a great home market and the right export dealership network.

Read profile

Engine info

Product overview

Gallery

Related case studies

Delivering an all-terrain performance

It is often said that there is no substitute for experience. It’s certainly a wisdom which the team at Bomford Turner wholeheartedly agree with. Pioneering innovative design in engineering since the late 1800s, Bomford has always been a leader in its field.

Based in Worcestershire, UK, the Bomford team are rightly very proud of the quality state-of-the-art machinery they offer their loyal customers including contractors, farmers and local authority workers.

Over the years Bomford has enjoyed increasing success and impressive business growth which it attributes to several factors including a range of innovative products, to having a great home market and the right export dealership network.

For the past five years one of Bomford’s most notable applications has been the Flailbot, a wirelessly operated track mower that’s ideally suited to difficult terrains such as mountain sides, reservoir banks, roadsides and oil refineries.

Covering challenging, steeply inclined terrain with a traditional man-on-board power mower can put a driver at risk, so the remotely controlled Flailbot provides the required mowing capability while keeping the operator at a safe distance.

Used in both the agricultural and amenities sectors, the Flailbot boasts a huge array of attachments, meaning there is always a different implement to offer its wide range of customers.

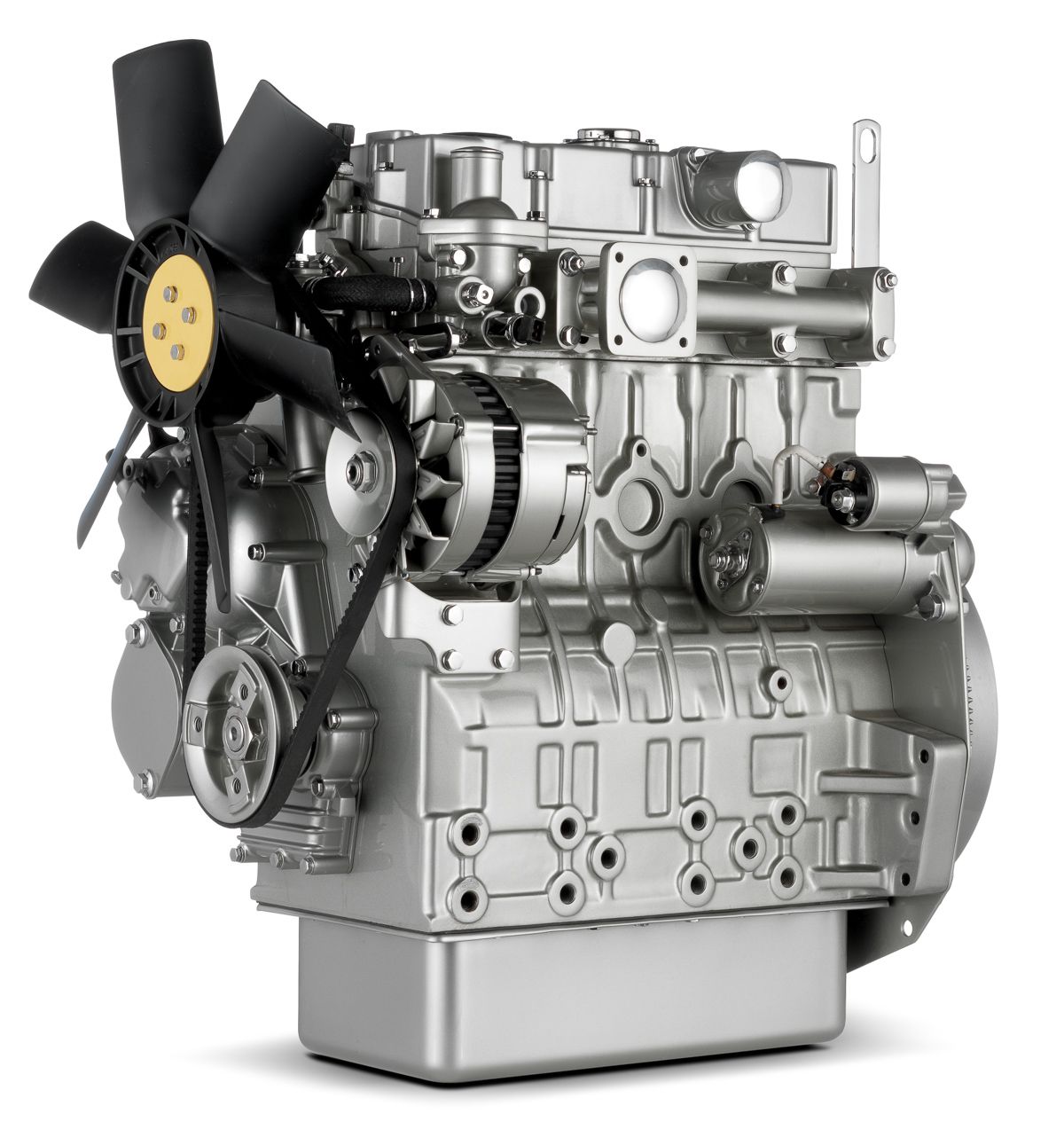

The compact, original, extra and supreme models are currently powered by Perkins three and four cylinder 400 Series engines meeting EU Stage IIIB emission standards and will soon be fitted with the latest Stage V Perkins engines built in Peterborough, UK.

Rhys Thomas, Bomford’s Flailbot product specialist said: “One of the main USPs for the Flailbot that myself and the rest of the sales team use, is the fact that it has a Perkins engine. From the better fuel economy offered to the extreme reliability and less noise pollution than our competitors.”

He continued: “Also, the fact that every customer who has had experience of a machine with a Perkins power unit has gone on to then mention themselves about how reliable they were. And finally, the fact that it is a British company really does go down well with the customer.”

For Bomford and its customers, the reassurance of immediate on the ground support from Perkins’ UK distributor, Diperk Power Solutions, is also another reason for staying Perkins-powered.

“The field service support that has been offered by DiPerk is a great selling point but as yet due to the reliability of the engine we have not needed any support,” said Sam Sharp, Bomford’s parts sales manager.

“It is great being able to offer the fact that Diperk will support us on visits should any engines fail.”

Thanks to the 400 Series engines fitted in the Flailbot, it delivers ample power and torque, and performs reliably under arduous or extended duty, without overheating. The whole powertrain has been designed and tested to work continuously, even on gradients of up to 55°.

Sam continued: “One huge benefit that we have had from the relationship with Perkins has been the reliability. We have not had one single major breakdown. When machines have stopped, parts were extremely easy to get hold of and get our customers back working.”

“One of the main USPs for the Flailbot that myself and the rest of the sales team use, is the fact that it has a Perkins engine. From the better fuel economy offered to the extreme reliability and less noise pollution than our competitors."

Rhys Thomas, Bomford’s Flailbot product specialist

Services

Discover more about some of the additional services Perkins can offer you.