We worked hard to find a solution when a customer asked us to reduce the low idle speed in their machines while also allowing them to apply full hydraulic load at the lowest idle condition. We delivered this by fitting electronic control to the 400 Series engine.

This not only reduced high and low idle speeds, but because operators could now use their machines at lower speeds, it reduced fuel consumption too.

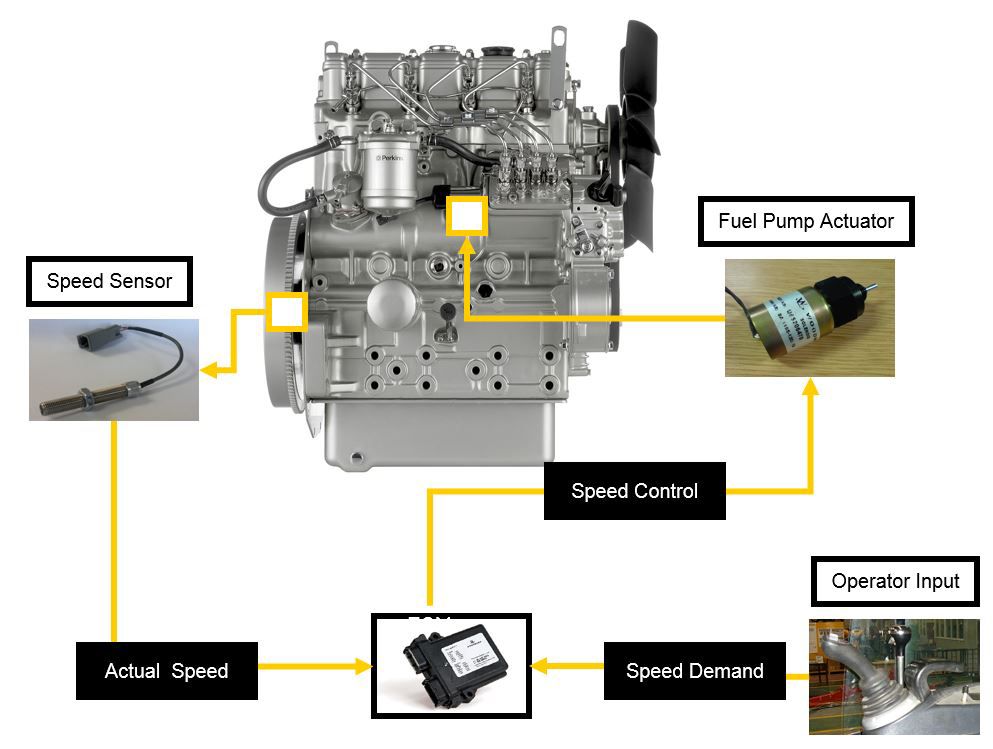

Traditionally, low-cost diesel engines have mechanical governing, by which the speed of the engine is selected – high to low. The machine applies a load to the flywheel to slow it down and the mechanical governing device introduces fuel to give the torque that balances the load that's applied. The system is entirely mechanical and allows you to select, for example, the engine to maintain 1000 rpm or 2000 rpm.

These mechanical systems are very low cost and very reliable.

Electronic systems, however, provide additional value by giving better speed control. On the 400 Series we now offer an electronic controller that works in tandem with the mechanical control to give you the benefits of both low-cost electronic control.

The development of this electronic governing (eGoverning) system on the 400 Series engines was in collaboration with a manufacturer of construction machinery, backhoe loaders and telescopic handlers.

The company wanted to reduce the low idle in its machines, including its latest excavator. At the lowest low idle condition, the company wanted to be able to put the full hydraulic load on to the machines without the engine stalling. A purely mechanically controlled engine wouldn't be able to do that.

With the electronic control on the engine it meant that there was nothing an operator could do to make the engine stall. It also meant that we were able to reduce high idle speed, which reduced engine noise and fuel consumption. Noise was also reduced at the lower low idle speed.

And, because the engine was robust enough to be operated under low idle speeds, operators were encouraged to use the machine under the low speed conditions which reduced fuel consumption.

By using eGoverning, we have given the long-established technology of our 400 Series engines a new lease of life, making them perform well in the most modern of machines.

The work done on this project has subsequently been picked up by a number of other customers. One manufacturer has made eGoverning a mandatory requirement on engines for its excavator applications.

Another has put eGoverning on its Perkins marine engines applications.

It’s by working in collaboration with our customers in this way that we continually meet their needs and exceed their expectations.

“We have demonstrated again that by working in close collaboration with our customers we can provide solutions to their needs- in this case giving long-established technology a new lease of life so that it performs well in modern society.” |

eGoverning fitted to the 400 Series engines:

If you're ready to receive trusted advice from a Perkins expert, speak to our team today.

Connect with usOur digital magazine with the latest news, interviews and analysis.

Read moreYour regional Perkins Distributor can provide local, on-the-ground engine support.

Learn More