The future of diesel-driven power generation keeps getting brighter

As modern diesel engines have been re-engineered to meet increasingly stringent emission standards, they also have become more efficient, not just in terms of fuel consumption, but also in the physical size of the new generation of engines. The size difference is quantified as ‘power density’ which means essentially generating more power in less space, all else being equal.

A more power dense engine delivers a competitive advantage for both Original Equipment Manufacturers (OEMs) and end-users in the diesel-driven electric power (EP) industry because an engine that produces more power from a smaller package can make a big difference to the bottom line. In addition to lower fuel consumption, the benefits include reduced shipping costs, smaller overall package sizes and the ability to fit more easily into confined spaces in increasingly crowded cities and locations where dependable standby power is needed.

In response, Perkins engineers focused on making dependable high power density engines a key design goal for all of their new products. The first new Perkins engines designed under this strategy for the EP industry were the 7-litre 1206, 9.3 litre 1706 and 18 litre 2806.

The trend accelerates

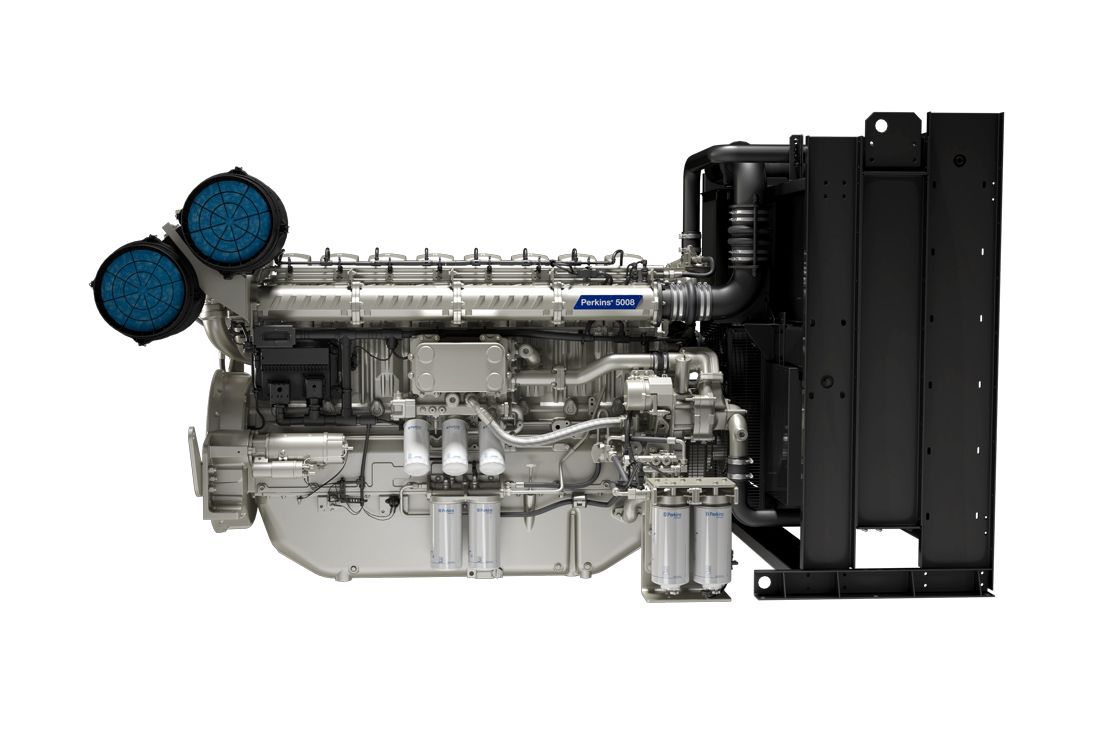

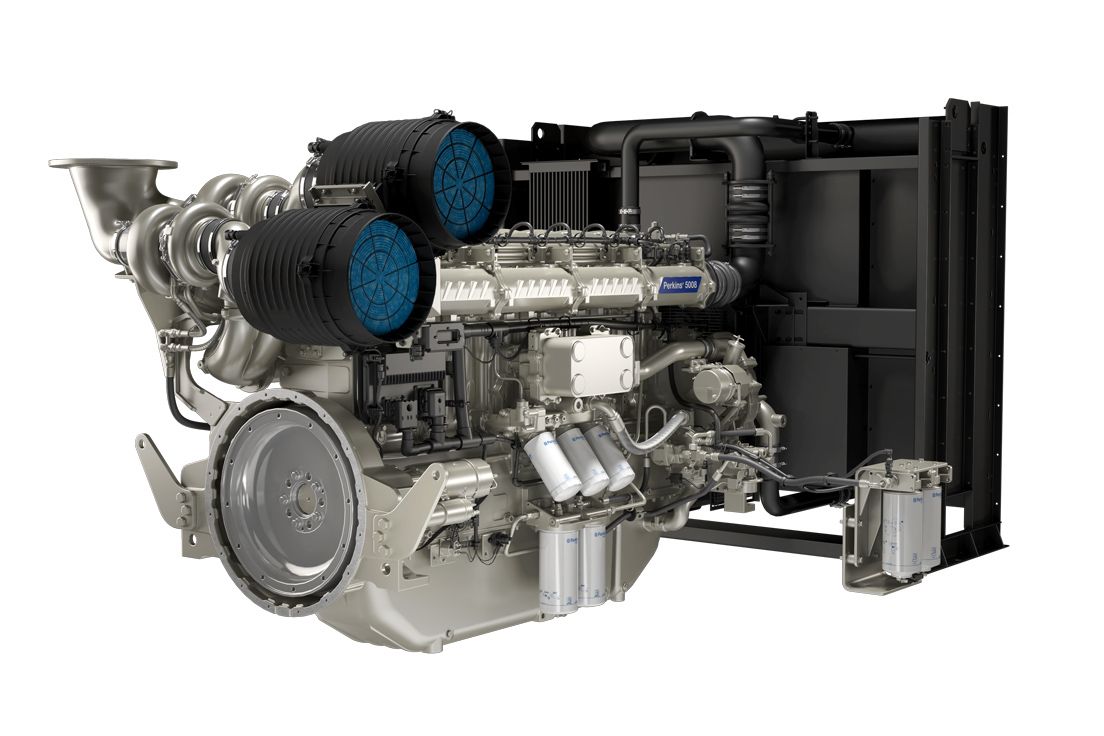

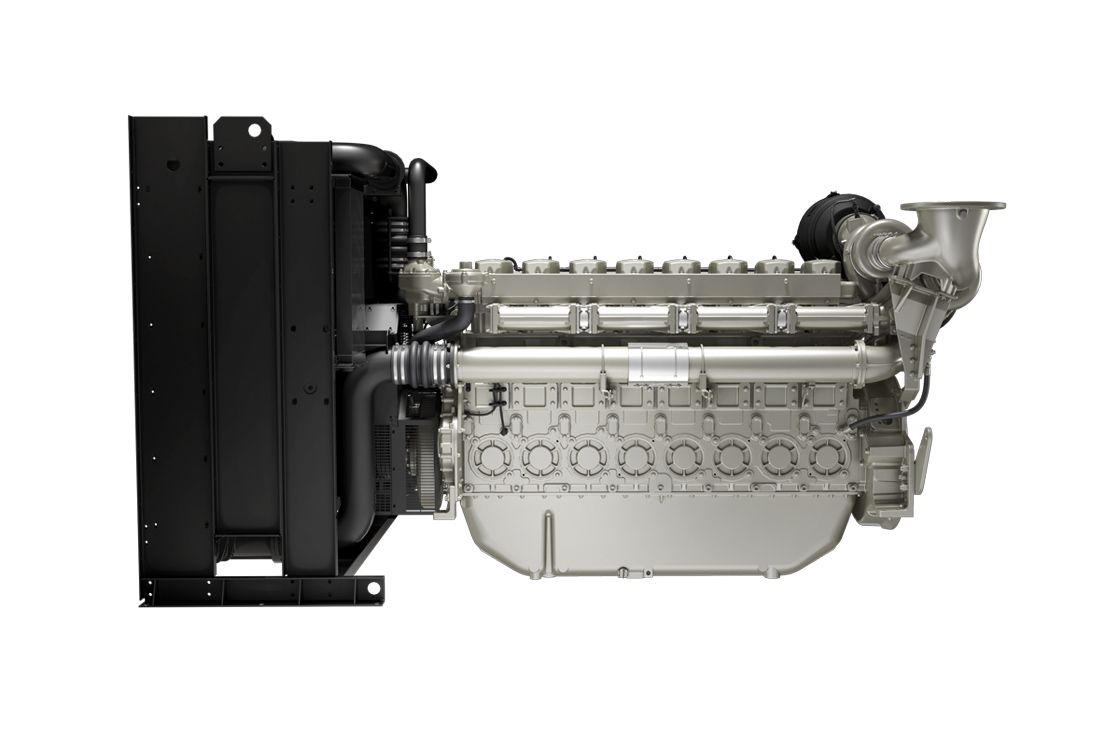

Building on that experience, and responding to customer requests for an even larger powered product, Perkins engineers began developing the 5000 Series engine, the first of which, the 5008C-E30TAG, was introduced in North America in February 2021. It is a high power density, 8-cylinder inline turbocharged and air-to-air charge cooled diesel displacing 30.56 litres, available configured as 900 and 1000 kWe standby power nodes.

“With multiple engine models offering a substantial power output of up to 1500 kWe the 5000 Series is ideal for a 1.5 MWe generator set. Every aspect of the new 5000 Series engine range, from its load acceptance capabilities to custom created components and innovative engineering techniques, has been designed to optimise customers’ needs for quick, reliable and cost-effective power,” said Americas sales director Bill Giunta.

Targeted at the market for emergency and standby power for critical applications like hospitals and data centres, the new engines offered the engineers a few new challenges.

Foremost of these was the ability to meet NFPA 110 Type 10 and ISO 8528-5 G2 and G3 standards for critical applications. In practical terms that means the engine has to achieve full recovery after first load step within 13 seconds.

5000 Series product manager, Steve Chesworth explained the challenge this way, “The engine’s ability to very quickly deliver stable backup power is a vital requirement for critical applications. Drawn on nearly nine decades of engine-design and manufacturing expertise, the 5000 Series is the culmination of many years of research, development and rigorous testing. Throughout that time, we’ve focused on delivering what our customers have asked for—cost-effective and reliable power—and we’re confident the

5008C-E30TAG will exceed their expectations.”

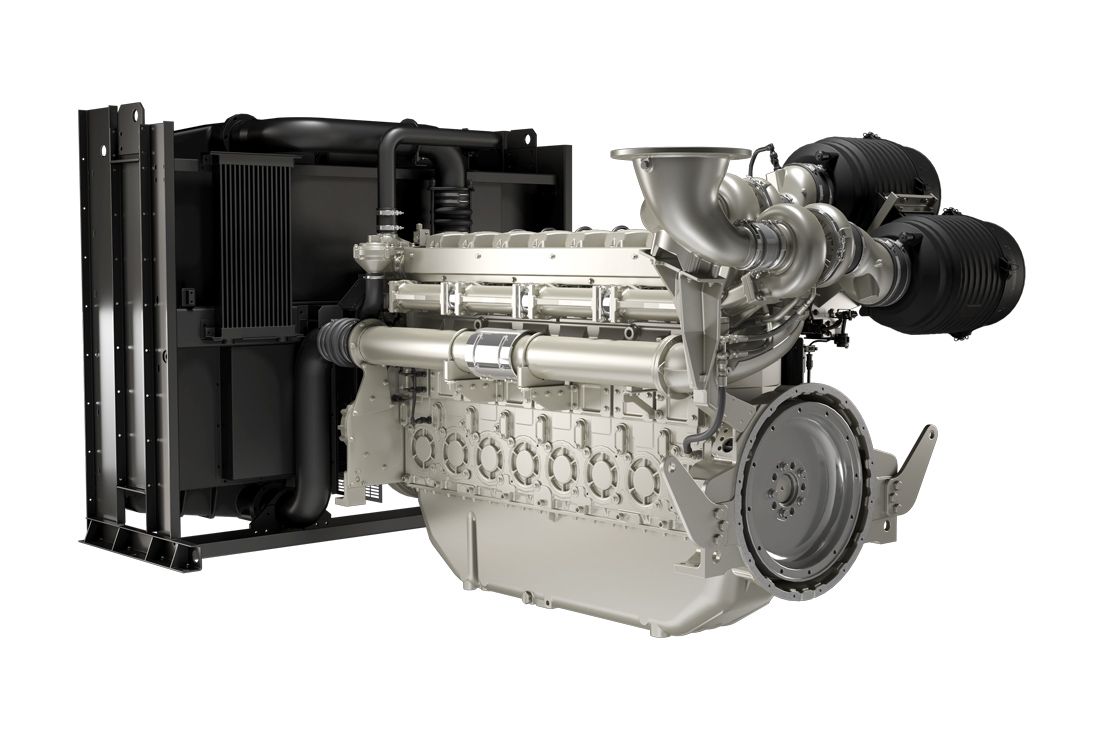

The engine has newly designed connecting rods, crank and camshafts, cylinder block and head all specifically designed for the 5000 Series engines. The 8-cylinder inline block is 8 percent narrower than the previous generation 12-cylinder V-block that produced the same output yielding an overall power density that is 11 percent greater.

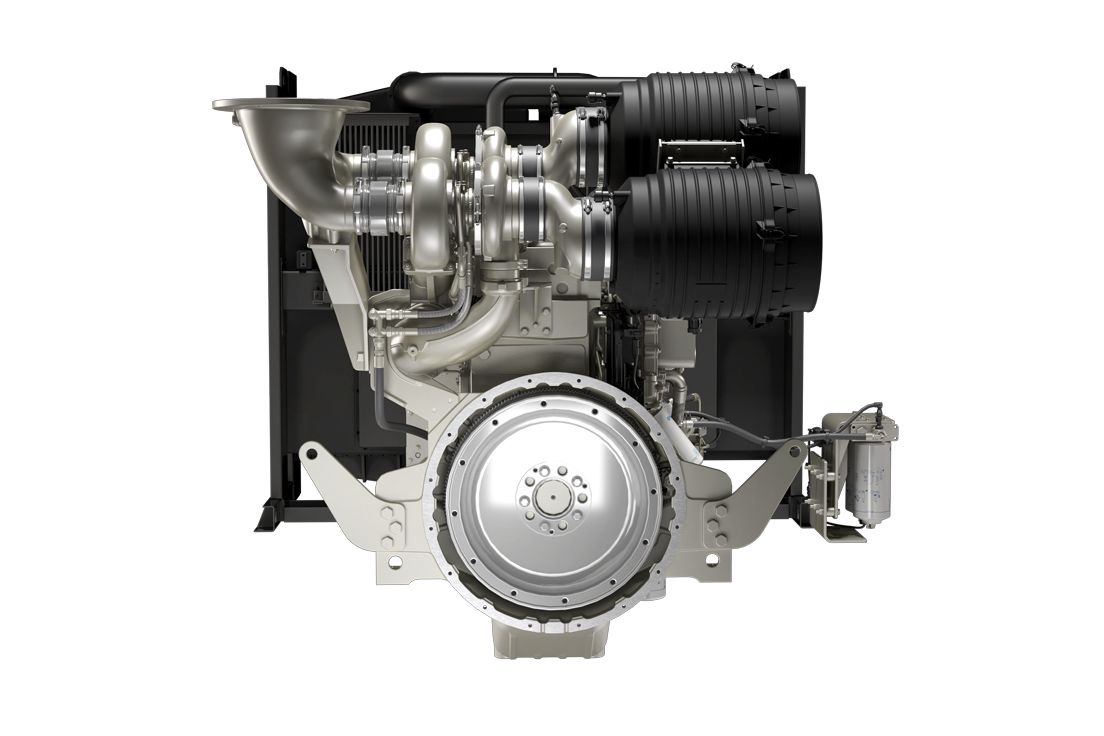

To achieve the load acceptance goals Perkins engineers used an innovative design with two smaller turbochargers on each cylinder bank which are specifically matched to the engine’s power rating. The smaller turbos have less inertia so they get up to speed faster than a single larger unit. The turbos also feature titanium compressor wheels that can withstand higher operating temperatures and ball bearing centre housings to minimise friction and further improve responsiveness. Exhaust gas flow to the turbos has been optimised to reduce ramp-up time.

The engineers also fine-tuned the fuel injector flow rate and nozzle configuration to work with an enhanced camshaft design and high peak cylinder pressures to minimise fuel consumption while achieving high power density. The camshaft has optimised valve timing to improve exhaust gas flow and work with the turbocharger to optimise load acceptance and fuel consumption.

The fuel system is electronically controlled to optimise fuel delivery and timing during transient response. The electronics provide fully controllable injection pressure and timing. The system can vary the beginning and end of the injection cycle and the injection rate during the cycle to optimise fuel economy while meeting emission requirements.

An advanced sealing technology utilising urethane bead gaskets was selected to reduce operational wear and potential leaks and a new piston, ring and liner assembly was developed to minimise oil consumption. It features an enhanced ring groove profile on the piston, a new ring profile and coating and a new liner surface finish.

A patent pending cylinder cut-out and cranking software strategy improves cold start and light load running capabilities. The standard cooling system supports operation in ambient temperatures up to 50° C without derating.

5000 Series engines are equipped with an integrated ECM and sensor pack that easily integrates with existing telematic ecosystems to simplify adoption and deployment regardless of the current infrastructure. They also have been certified for use around the world to simplify implementation.

As diesel technology continues to improve, the future of the diesel-driven EP industry promises to be one of increasing efficiency, higher reliability and lower operating costs.

Virtual product tours

When emergency standby power is essential to your day-to-day operations, you need an engine that’s ready to get the job done.

5008

5012

Got something to say?

Share this story and get involved in the conversation on social media #Powernews

Related articles

-

Powering forward: Richard Hemmings on innovation, reliability and what comes next

Powernews caught up with new VP Richard Hemmings to learn more about his new role.

Read more -

Rewriting the rules of power: The electric unit driving the next wave of innovation

The Perkins battery-electric power unit continues to attract interest among original equipment manufacturers (OEMs).

Read more -

Perkins® 904 Series: pushing the boundaries

The new model will deliver up to 129 kW (173 hp) and 740 Nm (546 lb ft) at 1500 rpm, from a compact 3.6 litre engine.

Read more -

Built to make a difference: The new 5000 Series is driving progress around the world

Providing dependable power output up to 2500 kVA for standby and 2250 kVA for prime applications.

Read more